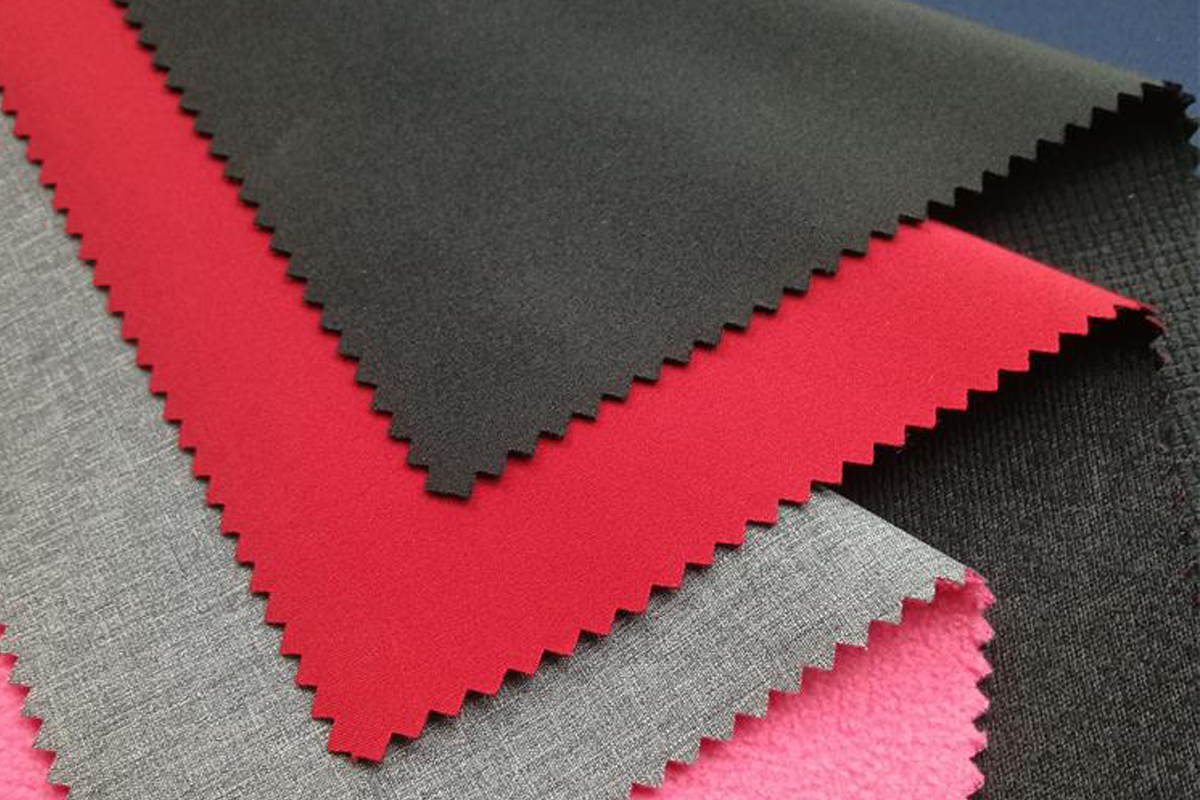

Lesela le thatae fetotse saense ea lintho tse bonahalang ka 2025. Liindasteri joale li itšetlehile ka thepa ea tsona e tsoetseng pele ho fihlela litlhoko tsa sejoale-joale. Mohlala,Lesela la mekhahlelo e 'melie ntlafatsa ts'ebetso maemong a feteletseng, halesela la baki le sa keneleng metsie netefatsa ho tšoarella le tšireletso. Mekhoa ena e mecha e hlalosa bocha ts'ebetso, e fana ka litharollo tse leka-lekanyang matla, boiketlo le botsitso.

Lintlha tsa Bohlokoa

- Lesela le thata le ntlafalitsoe haholo bakeng sa maemo a thata. Mehopolo e mecha joalo ka lera la ePE le masela a bohlale a etsa hore le be betere.

- Ho bae sireletsa tikolohoho bohlokoa. Mealo e se nang PFAS le thepa e bolang e thusa polanete ha e ntse e le matla.

- Liindasteri tse fapaneng le lisebelisoa tsa AI lia sebelisoaho sebetsa 'mohoBa etsa bonnete ba hore masela a lumellana le litlhoko tse ngata 'me a lula a le matle bakeng sa tlhaho.

Lintlafatso tsa Bohlokoa Theknolojing ea Lesela la Hardshell

Li-membrane tse tsoetseng pele tse phefumolohang joalo ka theknoloji ea ePE

Mara a phefumolohangli bile le tsoelo-pele e kholo, ka theknoloji e atolositsoeng ea polyethylene (ePE) e etellang pele. Tlhahiso ena e fana ka tharollo e bobebe empa e tšoarella haholo bakeng sa lesela la hardshell. Ho fapana le li-membrane tsa setso, ePE e ntlafatsa taolo ea mongobo ka ho lumella mouoane oa metsi ho tsoa ha o ntse o thibela mongobo o kantle. Sebopeho sa eona se senyenyane se ntlafatsa ho hema ntle le ho beha metsi kotsing. Barati ba kantle le baatlelete ba rua molemo theknolojing ena, kaha e netefatsa boiketlo nakong ea mesebetsi e matla haholo. Bahlahisi ba boetse ba ananela ts'ebetso ea eona ea tlhahiso e mosa ho tikoloho, e fokotsang tšebeliso ea matla le litšila.

Liaparo tse bohlale bakeng sa ho itlhoekisa le ho laola mocheso

Liaparo tse bohlale li emela tsoelo-pele ts'ebetsong ea lesela. Liaparo tsena li nolofalletsa lesela le thata ho leleka litšila le matheba, li boloka ponahalo e hloekile ka boiteko bo fokolang. Ho feta moo, litšobotsi tse laolang mocheso li lumella lesela ho ikamahanya le maemo a tikoloho. Mohlala, aparo a ka bonahatsa mocheso maemong a leholimo a futhumetseng kapa a boloka mofuthu maemong a batang. Ts'ebetso ena e habeli e etsa hore aparo a bohlale a be a loketseng liaparo tsa kantle le liaparo tsa mosebetsi, moo ts'ebetso le boiketlo li leng tsa bohlokoa ka ho fetisisa.

Li-laminate tse se nang PFAS bakeng sa ho thibela metsi ka mokhoa o tsitsitseng

Phetoho e lebisang ho tsitsitseng e susumelitse nts'etsopele ea li-laminate tse se nang PFAS. Li-laminate tsena li fana ka tšireletso e sebetsang ea ho thibela metsi ntle le ho itšetleha ka lintho tse kotsi tsa per- le polyfluoroalkyl. Ka ho felisa PFAS, bahlahisi ba sebetsana le matšoenyeho a tikoloho ha ba ntse ba boloka maemo a holimo a ts'ebetso a lebelletsoeng bakeng sa lesela la hardshell. Tlhahiso ena e tšehetsa liindasteri tse ikemiselitseng ho fokotsa khatello ea tsona tikolohong, haholo-holo liaparong tsa kantle le lits'ebetsong tsa indasteri.

Nanotechnology bakeng sa ho tšoarella le ho matlafatsa

Nanotechnology e fetotse ho tšoarella ha lesela le thata. Ka ho kopanya likaroloana tsa nanoscale sebopehong sa lesela, bahlahisi ba fumana matla le ho hanyetsa ho tsofala le ho taboha ho sa tloaelehang. Ntlafatso ena e atolosa bophelo ba lihlahisoa, e fokotsa tlhoko ea ho nkeloa sebaka khafetsa. Litšebeliso li tloha ho lisebelisoa tse thata tsa kantle ho ea ho liaparo tsa mosebetsi tse sireletsang, moo ho tšoarella ho leng bohlokoa. Nanotechnology e boetse e nolofalletsa meralo e bobebe, e netefatsang hore matla ha a tle ka litšenyehelo tsa boiketlo.

Litšebeliso tsa Hardshell Fabric Across Industries

Lisebelisoa tsa kantle: Tshebetso maemong a feteletseng

Lesela le thata le fetohile lejoe la motheo la thepa ea kantle, le fanang ka ts'ebetso e sa bapisoeng maemong a feteletseng. Thepa ea lona e sa keneleng metsi le e sa keneleng moea e sireletsa bahahlauli boemong ba leholimo bo bobe, e netefatsa polokeho le boiketlo. Li-membrane tse tsoetseng pele tse phefumolohang, joalo ka theknoloji ea ePE, li ntlafatsa taolo ea mongobo, li thibela ho chesa haholo nakong ea mesebetsi e matla. Bahahlauli ba lithaba, ba hahlaulang lithaba, le ba hloa lithaba ba itšetlehile ka lesela lena bakeng sa ho tšoarella ha lona ho bobebe, ho fokotsang mokhathala ntle le ho beha tšireletso kotsing. Bahlahisi ba boetse ba kopantse liaparo tse bohlale, tse nolofalletsang liaparo tsa kantle ho itlhoekisa le ho laola mocheso. Lintho tsena tse ncha li khotsofatsa tlhoko e ntseng e hola ea lisebelisoa tse tšepahalang, tse sebetsang hantle libakeng tse thata.

Kaho: Polokeho le ho tšoarella ha liaparo tsa mosebetsi

Indasteri ea kaho e hloka liaparo tsa mosebetsi tse behang pele polokeho le ho tšoarella. Lesela le thata le fihlela litlhoko tsena ka ho fana ka khanyetso e ikhethang khahlanong le maqeba, meokho le lik'hemik'hale tse matla. Tsoelo-pele ea nanotechnology e matlafalitse lesela haholo, e atolosa nako ea bophelo ea liaparo tse sireletsang. Basebetsi ba rua molemo meralong e bobebe e ntlafatsang ho tsamaea ha ba ntse ba boloka tšireletso e matla. Ho feta moo, li-laminate tse se nang PFAS li netefatsa ho thibela metsi ntle le lik'hemik'hale tse kotsi, li lumellana le boiteko ba indasteri ba ho amohela mekhoa e tsitsitseng. Ho tloha ho lihelmete ho ea ho lijakete, lesela le thata le bapala karolo ea bohlokoa ho sireletseng litsebi tsa kaho.

Feshene: Ho kopanya setaele le tshebetso

Baqapi ba feshene ba amohetse lesela la hardshell ka lebaka la bokhoni ba lona ba ho kopanya setaele le ts'ebetso. Ponahalo ea lona e boreleli le thepa ea lona e feto-fetohang li etsa hore e be khetho e ntle bakeng sa liaparo tsa litoropo le feshene e sebetsang hantle. Liaparo tse bohlale li lumella liaparo ho lula li hloekile le ho ikamahanya le liphetoho tsa mocheso, li hohela bareki ba batlang boiketlo le boiketlo. Baqapi ba boetse ba sebelisa tlhaho ea lesela e bobebe empa e tšoarella ho etsa likarolo tse ncha tse mamellang ho aparoa letsatsi le letsatsi. Ka ho kenyelletsa thepa e tsitsitseng le mekhoa ea tlhahiso, indasteri ea feshene e lumellana le mekhoa e hlokomelang tikoloho ha e ntse e fana ka liaparo tse ntle le tse sebetsang.

Tšusumetso ea Tikoloho le Botsitso ba Tikoloho

Mekhoa ea tlhahiso e sireletsang tikoloho le ho fokotsa khabone

Bahlahisi ba amohetsemekhoa ea tlhahiso e sireletsang tikolohoho fokotsa tšusumetso ea tikoloho ea lesela la hardshell. Mekhoa ena e kenyelletsa ho sebelisa mehloli ea matla a nchafatsoang, joalo ka matla a letsatsi le a moea, nakong ea ts'ebetso ea tlhahiso. Mechine e tsoetseng pele e boetse e fokolitse tšebeliso ea matla ka ho ntlafatsa katleho. Mekhoa ea ho daea ntle le metsi e fumane botumo, e felisa tlhoko ea metsi a mangata le lik'hemik'hale tse kotsi. Ka ho kenya tšebetsong mekhoa ena, lik'hamphani li theotse haholo carbon footage ea tsona. Phetoho ena ha e ruise tikoloho molemo feela empa hape e tsamaisana le tlhoko ea bareki bakeng sa lihlahisoa tse tšoarellang.

Ho sebelisa hape le ho sebelisa hape thepa ea masela

Ho sebelisa hape le ho sebelisa hape lintho tse ncha e se e le karolo ea bohlokoa tlhahisong ea masela. Likhamphani joale li bokella litšila tse setseng bareki, joalo ka liaparo tse lahliloeng le masalla a indasteri, ho etsa lesela le lecha la hardshell. Ts'ebetso ena e fokotsa ho itšetleha ka thepa e sa tsoa sebelisoa 'me e thibela litšila ho fella libakeng tsa ho lahla lithōle. Ho sebelisa hape lintho tse ncha ho nka bohato bo eketsehileng ka ho fetola thepa ea khale hore e be lihlahisoa tsa boleng bo holimo. Mohlala, bahlahisi ba sebelisa hape liaparo tse sebelisitsoeng tsa kantle hore e be liaparo tsa mosebetsi tse tšoarellang kapa likotoana tsa feshene tse fesheneng. Mekhoa ena e khothalletsa moruo o chitja, moo mehloli e sebelisoang hape ho e-na le ho lahloa.

Lisebelisoa tse bolang bakeng sa moruo o chitja

Nts'etsopele ea thepa e bolang e fetotse botsitso ba lesela la hardshell. Lisebelisoa tsena li bola ka tlhaho ha nako e ntse e ea, ha li siee masala a kotsi. Bo-rasaense ba entse li-polymer tse thehiloeng linthong tsa tlhaho tse tsoang mehloling e nchafatsoang, joalo ka cornstarch le bolele, ho nkela likhoele tsa maiketsetso tsa setso sebaka. Lesela la hardshell le bolang le fana ka ho tšoarella le ts'ebetso e tšoanang le likhetho tsa setso ha ka nako e ts'oanang le netefatsa ho lumellana ha tikoloho. Tlhahiso ena e tšehetsa moruo o chitja ka ho fokotsa litšila le ho khothaletsa ho khutlela ha thepa tlhahong.

Mekhoa ea Nakong e Tlang ea Theknoloji ea Lesela la Hardshell

Moralo le mokhoa oa ho iketsetsa lesela o tsamaisoang ke AI

Bohlale ba maiketsetso (AI) bo fetola moralo oa lesela ka ho nolofalletsa maemo a sa tloaelehang a ho iketsetsa. Baqapi joale ba sebelisa li-algorithms tsa AI ho sekaseka likhetho tsa bareki, maemo a tikoloho le litlhoko tsa ts'ebetso. Mokhoa ona o tsamaisoang ke data o lumella bahlahisi ho etsa masela a etselitsoeng litlhoko tse itseng. Mohlala, AI e ka ntlafatsa ho beoa ha lera le phefumolohang kapa ea ntlafatsa ho tšoarella libakeng tse nang le khatello e phahameng. Ho etsa mohlala oa ho bolela esale pele ho boetse ho thusa ho khetholla mefokolo e ka bang teng moralong oa lesela pele tlhahiso e qala. Tlhahiso ena e ncha e fokotsa litšila tsa thepa 'me e potlakisa linako tsa nts'etsopele. Ho iketsetsa ho tsamaisoang ke AI ho netefatsa hore bareki ba fumana lihlahisoa tse lumellanang le litlhoko tsa bona tse ikhethang, ebang ke tsa liaparo tsa kantle, liaparo tsa mosebetsi, kapa feshene.

Tšebelisano-'moho ea indasteri e fapaneng bakeng sa boqapi

Tšebelisano-'moho lipakeng tsa liindasteri e se e le tšusumetso e susumetsang tsoelo-pele ea theknoloji ea masela. Tšebelisano-'moho pakeng tsa bahlahisi ba masela, lik'hamphani tsa theknoloji le litsi tsa lipatlisiso li khothalletsa phapanyetsano ea boiphihlelo le lisebelisoa. Mohlala, lifeme tsa nanotechnology li kenya letsoho nts'etsopele ea thepa e matla le e bobebe, ha mekhatlo ea tikoloho e tataisa mekhoa e tsitsitseng. Tšebelisano-'moho ena e potlakisa boqapi ka ho kopanya maikutlo a fapaneng le lisete tsa tsebo. Likhoebo tse kopanetsoeng li boetse li nolofalletsa ho kopanngoa ha mahlale a morao-rao, joalo ka lipente tse bohlale kapa thepa e bolang, tlhahisong ea masela. Boiteko ba indasteri e fapaneng bo netefatsa hore lesela le thata le ntse le tsoela pele ho fetoha, le fihlela litlhoko tsa makala a fapaneng.

Ho atolosa ho amoheloa ha mekhoa e tsitsitseng

Ho tšoarella ho ntse ho le ntho ea bohlokoa indastering ea masela. Likhamphani li ntse li amohela mekhoa e fokotsang tšusumetso tikolohong. Tsena li kenyelletsa ho sebelisa matla a nchafatsoang, thepa ea ho sebelisa hape, le ho nts'etsapele mekhoa e ka bolang. Mebuso le bareki ka ho tšoana ba khanna phetoho ena ka ho batla lihlahisoa tse sireletsang tikoloho. Baetapele ba indasteri ba arabela ka ho beha lipheo tse kholo tsa ho tšoarella le ho tsetela mahlaleng a matala. Ho amoheloa ha mekhoa ena ka bongata ha ho tsoele polanete molemo feela empa hape ho ntlafatsa botumo ba lets'oao. Ha ts'ireletso e ntse e fetoha ntho e tloaelehileng, e tla bopa bokamoso ba tlhahiso ea masela le ho hlalosa bocha maemo a indasteri.

Thetsoelo-pele theknolojing ea leselaba hlalositse bocha ho tšoarella, ts'ebetso le botsitso. Liindasteri joale li rua molemo litharollong tse ncha tse ntlafatsang ts'ebetso ha ka nako e ts'oanang li fokotsa tšusumetso ea tikoloho. Lintlafatso tsena li khanna tsoelo-pele ho pholletsa le makala, ho tloha lisebelisoa tsa kantle ho ea fesheneng. Boiqapelo bo tsoelang pele bo ntse bo le bohlokoa bakeng sa ho sebetsana le liphephetso tsa nakong e tlang le ho netefatsa hore thepa e fihlela litlhoko tse ntseng li fetoha.

LBH

Ke eng e etsang hore lesela la hardshell le fapane le lesela la softshell?

Lesela la Hardshell le fana ka tšireletso e ntle ea ho thibela metsi le ho thibela moea, e leng se etsang hore e be ntle bakeng sa maemo a feteletseng. Lesela la Softshell le etelletsa pele ho hema le ho tenyetseha, le loketse boemo ba leholimo bo itekanetseng le motsamao o mafolofolo.

Nanotechnology e ntlafatsa lesela la hardshell joang?

Nanotechnology e ntlafatsa ho tšoarella ka ho kopanya likaroloana tsa nanoscale ka har'a lesela. Tlhahiso ena e eketsa ho hanyetsa ho tsofala le ho taboha ha e ntse e boloka thepa e bobebe bakeng sa boiketlo le ho tsamaea.

Na li-laminate tse se nang PFAS li sebetsa hantle joalo ka ho thibela metsi ka mokhoa oa setso?

E, li-laminate tse se nang PFAS li fana ka tšireletso e ntle ea ho thibela metsi ntle le lik'hemik'hale tse kotsi. Li fihlela maemo a ts'ebetso ha li ntse li tšehetsa botsitso ba tikoloho, e leng se etsang hore e be khetho e ratoang bakeng sa bahlahisi ba hlokomelang tikoloho.

Nako ea poso: Hlakola-22-2025