Massive Selection for Herringbone Wool Suit Fabric - 30% wool suit fabric wholesale good quality – Yun Ai Detail:

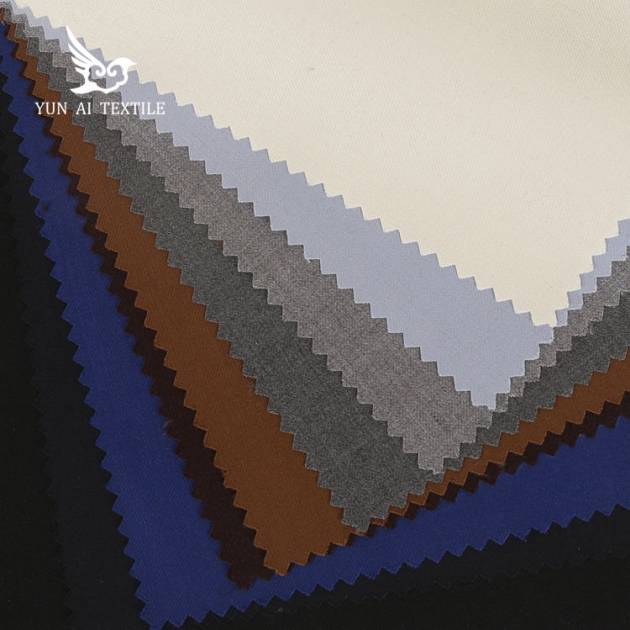

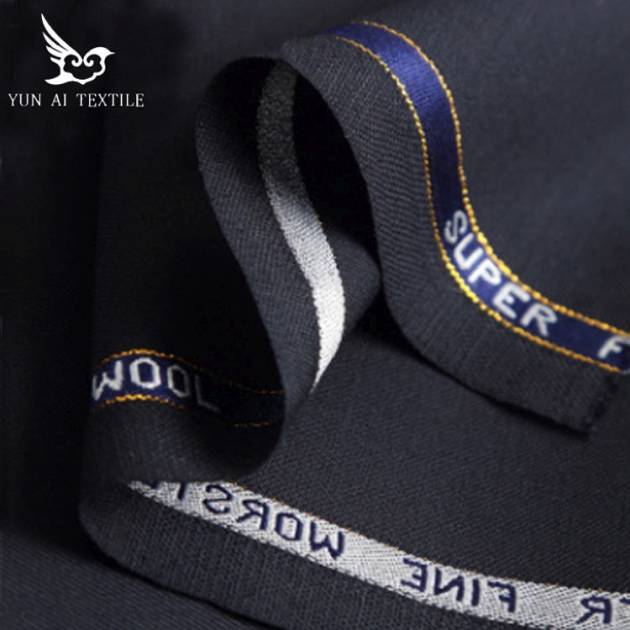

Now more and more customers are looking for high-end wool suit fabric instead of low-end polyester/viscose suit fabric. Use natural wool suit fabrics to make ready-made suits look stiffer. In the process of process improvement from polyester/viscose suit fabric to wool suit fabric, the process was also improved step by step. A small amount of wool was used to replace viscose fabric at first, rather than replacing it directly with whole wool. The process progress was a slow process. So the first thing we tried was to add 30% wool yarn. The best merino wool is twisted into the highest quality yarn, and then woven with 69.5 polyester yarns. After continuous testing, this process finally matures and becomes popular among consumers all over the world. The characteristic of this kind of suit fabric is that the cost is much lower than the whole wool, and the antistatic wire is added, so the whole fabric is no longer chafed, which increases the safety. It also makes the occasion of wearing wool suit no longer limited, not only suitable for office space, more workers also began to wear wool suit fabric, giving people confidence and temperament. Help people attend important events.

Wool blended fabric has a stiff feeling, and with the increase of polyester content and obviously prominent.Wool blended fabrics have a dull luster.Generally speaking, worsted wool blended fabrics feel weak, rough feel is loose.In addition, its elasticity and crisp feeling is not as good as pure wool and wool-polyester blended fabrics.

Through leading industry practice in design, manufacturing and services, YunAi is committed to offering customers ‘best in class’ in the design, manufacture and supply of quality school uniforms fabric, airline uniforms fabric and office uniforms fabric. We take stock orders if the fabric is in stock, fresh orders also if you can meet our MOQ. In most situation, the MOQ is 1200 meters.

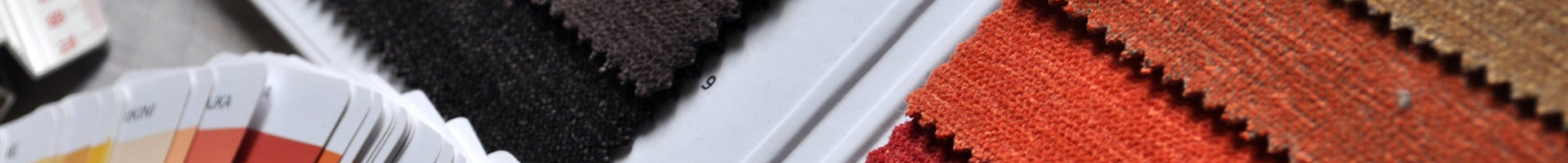

Product detail pictures:

Related Product Guide:

National High-Tech Industry

How to choose wool suit fabric?

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Massive Selection for Herringbone Wool Suit Fabric - 30% wool suit fabric wholesale good quality – Yun Ai , The product will supply to all over the world, such as: Belgium, Guyana, Malawi, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!