When I source polyester rayon fabric for menswear, I see price estimates for 2025 ranging from $2.70 to $4.20 per yard. The biggest price drivers come from raw material and energy costs. I always check for specialty options like TR 4 way stretcable for medical uniforms or Fancy blazer Polyester Rayon Plaid Design Stretch.

| Cost Component | Estimated Share of Total Cost | Key Influences and Notes |

|---|---|---|

| Dissolving Wood Pulp (DWP) | 50–65% | Affected by supply, regulations |

| Energy | 10–20% | Spinning, dyeing, finishing |

| Labor | 8–12% | Country-specific |

| Dyeing & Finishing | 8–15% | Technology, compliance |

| Certifications & Testing | 2–5% | Sustainability, compliance |

| Logistics & Admin | 3–5% | Freight, packaging, export |

I watch for What factors influence price in polyester rayon fabric? Market demand, new styles like Plaid Yarn Dyed Woven 300GM TR 70/30 Viscose/polye, and Fashion Cloth 4 Way Stretch 75 Polyester 19 Rayon often affect what I pay.

Key Takeaways

- Raw material costs like wood pulp and petroleum strongly affect polyester rayon fabric prices, so monitor market trends closely.

- Manufacturing details such as yarn thickness, fabric density, and dyeing methods impact cost and quality; choose wisely to balance price and performance.

- Negotiating bulk orders, timing purchases during slow seasons, and working with reputable suppliers help secure better prices and reduce risks.

What Factors Influence Price in Polyester Rayon Fabric?

Raw Material Costs

When I evaluate what factors influence price in polyester rayon fabric, I always start with raw material costs. Polyester relies on petroleum-based feedstocks, so its price moves with crude oil markets. Rayon, on the other hand, depends on dissolving wood pulp, which is sensitive to forestry regulations, supply chain disruptions, and environmental policies. For example, when China imposed export controls on bamboo pulp, I saw rayon prices spike by 35% in just three months. Volatility in wood pulp prices, ranging from $800 to $1,200 per metric ton, directly impacts the cost of rayon blends. Polyester prices tend to be more stable, but they still fluctuate with oil prices and global demand. I always monitor these trends because they set the baseline for fabric pricing.

Manufacturing Processes

Manufacturing processes play a huge role in determining what factors influence price in polyester rayon fabric. Polyester and rayon have different production requirements, which affect labor, energy, and quality control costs. I often refer to the following table to compare their cost structures:

| Cost/Production Factor | Rayon (Average) | Polyester (Average) |

|---|---|---|

| Fabric Cost per kg | $2.80 – $3.60 | $1.80 – $2.50 |

| Pre-treatment Requirement | High | Low |

| Labor Intensity | Moderate to High | Low |

| Wastage/Rework Rate | 6–12% | 1–3% |

| Cutting Precision | Low–Medium (distortion prone) | High (shape retention) |

| Stitching Stability | Needs care (slippage possible) | Stable, easy to stitch |

| Finishing Time | Longer (gentle treatment) | Faster (aggressive cycles) |

| Print Processing Cost | Higher (multiple steps) | Lower (fast, heat-fixed) |

| Rework Rate (average) | 8–12% | 2–4% |

Polyester’s lower labor intensity and higher production speed reduce costs by about 23% compared to rayon. Rayon requires more careful handling, longer finishing times, and higher quality assurance, which increases overhead. When I choose between these fibers, I always factor in these differences because they impact both price and production timelines.

Fabric Yarn Count and Density

Yarn count and fabric density are technical details that directly answer the question: What factors influence price in polyester rayon fabric? Yarn count measures the thickness of the yarn. Finer yarns (higher count) cost more but use less weight per meter. Fabric density, measured by ends per inch (EPI) and picks per inch (PPI), tells me how tightly the yarns are woven. Higher density means more yarn per unit area, which increases raw material costs. For example, if I select a fabric with high EPI and PPI, I know the GSM (grams per square meter) will be higher, and so will the price. Weaving costs also rise with density and loom complexity. I always calculate yarn usage and GSM to estimate the final cost, especially for custom orders.

Dyeing Methods and Other Finishings

Dyeing and finishing processes are major contributors when I consider what factors influence price in polyester rayon fabric. The choice of dyeing method—rope dip, jig, pad, or full-process—affects both cost and quality. Here’s a quick overview:

| Process Type | Specific Method/Process | Cost Range (yuan/meter) | Cost Impact Explanation |

|---|---|---|---|

| Dyeing Methods | Rope dip dyeing (polyester) | ~1.2 | Common batch dyeing; cost varies by fabric and color depth. |

| Full-process dyeing (poly-cotton) | ~2.7 | More complex, multiple fibers and steps, higher cost. | |

| Jig dyeing (chemical fibers) | <2.0 | Good for small batches; cost varies. | |

| Pad dyeing (high-density) | Higher than standard | Dense/thick fabrics cost more to dye. | |

| Finishing Processes | Polishing | 0.1 – 0.8 | Biological enzyme polishing costs more. |

| Calendering and ginning | ~0.5 – 0.6 | Adds unique appearance; cost depends on pattern. | |

| Soft finishing | 0.1 – 0.2 | Cost depends on softener used. | |

| Resin finishing | ~0.2 | Low cost, adds anti-wrinkle. | |

| Pre-shrinking | 0.2 – 0.8 | Improves stability; cost varies. | |

| Flocking | Variable (higher with complexity) | Adds 3D graphics; cost depends on width and pattern. | |

| Other Cost Factors | Warp shrinkage impact | +0.15 yuan/m per 1% shrinkage | Shrinkage reduces yield, raising unit cost. |

Natural dyeing methods can lower chemical and energy costs, but they limit color options and require more process control. I always weigh the benefits of advanced finishing—like pre-shrinking or flocking—against the added expense, especially for high-end or technical applications.

Supply Chain and Shipping

Supply chain and shipping disruptions have become a top concern when I assess what factors influence price in polyester rayon fabric. Geopolitical events, regulatory changes, and logistics bottlenecks can all drive up costs. For example:

- China’s export controls on bamboo pulp caused a rapid price surge for rayon.

- Russia’s banking restrictions delayed wood pulp shipments by up to 45 days.

- The EU’s new deforestation rules increased due diligence costs by up to 18%.

- Indonesia’s timber export ban strained global supply networks.

- Polyester prices react to crude oil volatility and shipping disruptions, though they benefit from more stable supply chains.

In 2025, I noticed ocean freight rates for textiles rising sharply. Asia-US West Coast container rates climbed 8% to $4,825 per 40-foot container, while East Coast rates hit $6,116. Port congestion and tariff changes add more uncertainty. Airfreight rates dropped slightly, but they remain much higher than ocean shipping. These trends mean I must budget for higher logistics costs and potential delays, especially for rayon-heavy blends.

Market Demand

Market demand is one of the most dynamic answers to what factors influence price in polyester rayon fabric. When demand surges in fashion, sportswear, or technical textiles, prices rise if supply cannot keep up. Economic downturns or shifts in consumer preferences can lower prices. For instance, the global textile market is projected to reach $974.38 billion by 2030, with polyester leading fiber growth at a 6.32% CAGR. Asia-Pacific dominates production and consumption, but supply chain diversification is shifting some manufacturing to Vietnam, Bangladesh, and Turkey. Sustainability trends and regulations, like the EU’s Extended Producer Responsibility, also push up demand for recycled and durable fibers, raising prices for certified products. I always track these trends to anticipate price movements and plan my sourcing strategy.

Sustainability and Certifications

Sustainability certifications and eco-friendly practices are increasingly important when I consider what factors influence price in polyester rayon fabric. Certifications like OEKO-TEX, GOTS, FSC, and GRS guarantee safety, responsible sourcing, and environmental care:

| Certification | Purpose |

|---|---|

| OEKO-TEX | Ensures textiles are free from harmful substances, guaranteeing safety for skin contact |

| GOTS | Certifies organic fiber content and environmentally friendly production methods |

| FSC | Confirms wood pulp is sourced from responsibly managed forests |

| GRS | Verifies recycled content and responsible manufacturing processes |

Eco-friendly manufacturing, such as using recycled polyester or low-impact dyes, often increases production costs. These higher costs translate into higher fabric prices, but they also add value by supporting brand image and meeting regulatory requirements. When I negotiate prices, I always consider the added value of sustainability certifications and the long-term benefits for my business.

Comparing Polyester Rayon Fabric Prices

Price per Yard or Meter

When I compare polyester rayon fabric prices, I always start with the price per yard or meter. Most suppliers quote prices based on the length of fabric you order. For bulk orders, I often see prices as low as $0.76 per meter for quantities above 100,000 meters. Smaller orders, such as 3,000 to 29,999 meters, usually cost around $1.05 per meter. These prices can shift based on market demand, fiber blend, and finishing options. Retail prices run higher because they cater to smaller buyers and offer more flexibility.

Quality Grades

Quality grades play a major role in pricing. I look for differences in yarn count, weave density, and finishing. Higher grades use finer yarns and tighter weaves, which increase both durability and cost. Specialty finishes, like anti-wrinkle or moisture-wicking, also add to the price. I always request samples to compare grades before making a large purchase.

Supplier Types: Wholesale vs. Retail

I notice a clear difference between wholesale and retail suppliers. Wholesale suppliers offer lower prices for large orders. For example, a 100,000+ meter order can drop the price to $0.76 per meter. Retailers, such as The Remnant Warehouse, focus on smaller quantities and sustainable sourcing. They often sell remnants or deadstock and may offer discounts, like 20% off for orders over 10 meters. However, retail prices per meter remain higher than wholesale rates due to added services and lower volumes.

| Order Quantity (meters) | Approximate Price per Meter (USD) |

|---|---|

| 3,000 – 29,999 | $1.05 |

| 30,000 – 99,999 | $0.86 – $0.965 |

| 100,000+ | $0.76 |

Hidden Costs and Minimum Order Quantities

I always watch for hidden costs and minimum order quantities (MOQs) when sourcing fabric. Most suppliers set MOQs between 100 and 300 meters, but some offer as low as 50 meters for standard blends. Lower MOQs are possible because of high demand and easy access to raw materials. However, I must consider setup costs, warehousing fees, and the risk of holding excess inventory. Smaller orders often come with premium pricing and less flexibility.

Tip: Always ask suppliers about hidden costs and negotiate MOQs to match your production needs.

Tips for Getting the Best Value

Negotiation Strategies

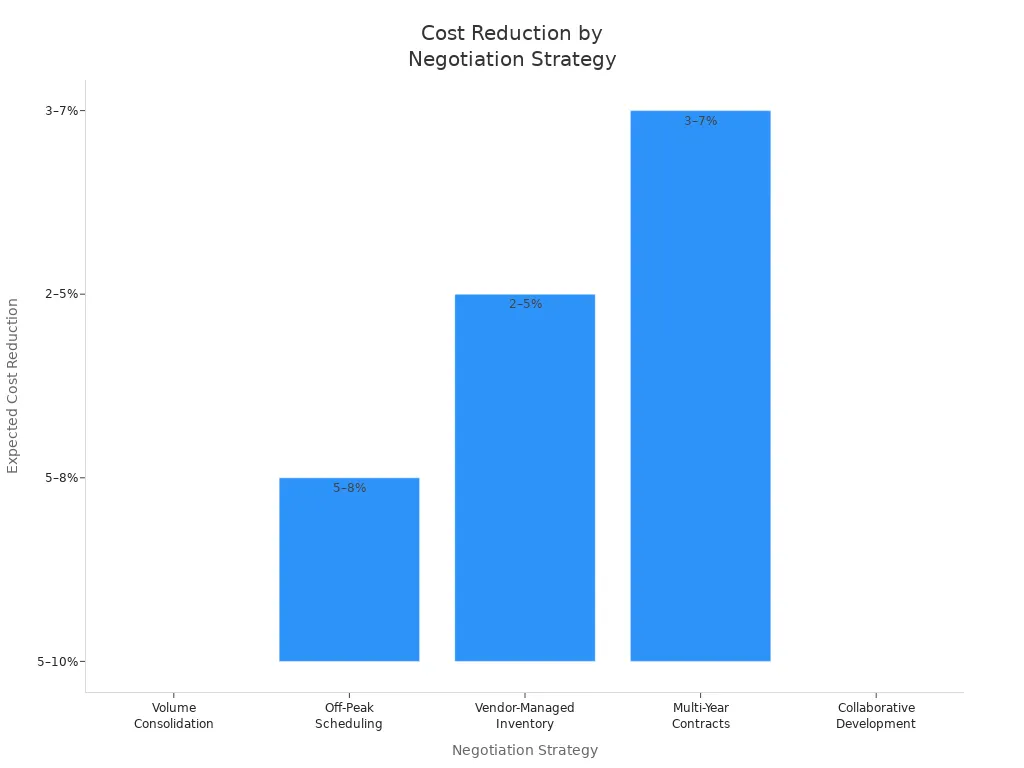

I always approach negotiations with a clear plan. The most effective strategies focus on volume, timing, and collaboration. Here’s a table that summarizes the key tactics I use and the typical savings I achieve:

| Strategy | Mechanism | Expected Cost Reduction |

|---|---|---|

| Volume Consolidation | Aggregating orders to meet MOQ | 5–10% |

| Off-Peak Scheduling | Ordering during slow seasons | 5–8% |

| Vendor-Managed Inventory | Supplier holds buffer stock | 2–5% |

| Multi-Year Contracts | Annual volume commitments | 3–7% |

| Collaborative Development | Co-designing to optimize costs | 5–10% |

Volume commitments and multi-year contracts help me secure long-term savings. I also find that working closely with suppliers on product development can unlock additional discounts.

Timing Purchases

I time my purchases to align with off-peak production periods. Mills often offer discounts when they need to fill capacity. By placing orders during slower months, I avoid surcharges and benefit from lower prices. This approach requires planning, but it consistently reduces my costs.

Evaluating Supplier Reputation

I never compromise on supplier reputation. I look for consistent quality, scalable production, and strong communication. The table below outlines my main criteria:

| Criteria Category | Key Points |

|---|---|

| Quality and Production | Consistent quality, scalable capacity, in-house testing |

| Sampling | Fast sampling, customization options, low sample charges |

| Communication and Documentation | Clear updates, technical sheets, shipment tracking |

| Certifications | FSC, OEKO-TEX®, GOTS, LENZING™ ECOVERO™ |

| Reputation and Referrals | Verified reviews, trade fair presence, export history |

| Ethical and Social Compliance | BSCI, SEDEX/SMETA, WRAP audits |

I rely on customer reviews and verified referrals. Strong supplier reputation reduces risks like defects and delays.

Considering Bulk Orders

Bulk orders always deliver better value. Larger quantities help me avoid small lot surcharges and unlock lower price tiers. I see significant price differences between minimum and large orders. Bulk buying also strengthens my supplier relationships, leading to priority service and future discounts. When I plan production, I prioritize bulk orders to maximize profit margins and minimize per-yard costs.

Tip: Buying in bulk not only lowers unit prices but also builds long-term supplier trust, which pays off in future negotiations.

Common Buyer Mistakes to Avoid

Overlooking Quality for Price

I often see buyers focus too much on price and ignore quality. This mistake can lead to several problems:

- Low-quality polyester wrinkles easily and shows wear before you even use it.

- Fabrics treated with chemical softeners may feel nice at first but lose their appeal quickly, becoming coarse or limp.

- High synthetic content, especially in polyester-heavy blends, usually means cost-cutting at the expense of durability.

- Poor construction shows up as uneven seams, misaligned patterns, and loose threads.

- Lack of certifications often signals hazardous manufacturing practices.

Tip: I always inspect fabric by touch and sight. I look for smoothness, uniform weave, and tight stitching. Modal and Lyocell, both rayon variants, offer better durability and comfort than basic rayon. Choosing these options helps me avoid environmental harm and ensures longer-lasting garments.

Ignoring Shipping and Duties

Shipping and duties can add unexpected costs to any order. I have learned to never underestimate these expenses. Freight rates fluctuate, and customs duties vary by country. If I ignore these factors, my budget can spiral out of control. I always ask suppliers for a detailed breakdown of shipping fees and import taxes before finalizing any deal.

- Ocean freight rates for textiles can rise sharply.

- Airfreight remains expensive compared to ocean shipping.

- Tariffs and duties differ by destination and can impact total landed cost.

Not Checking Return Policies

Return policies for polyester rayon fabric can be strict. Most suppliers do not accept returns on running meter fabrics unless there is a clear defect. Discounted items and swatches are usually non-returnable. If I need to return something, I must act fast—some suppliers only allow returns within three days of delivery, and the product must be unused and properly packed.

Note: I always review the supplier’s return policy before placing an order. I check if returns require email initiation, who pays for shipping, and how refunds are processed. This step helps me avoid costly surprises and ensures a smoother buying experience.

When I source polyester rayon, I always ask: What factors influence price in polyester rayon fabric? Key factors include raw material costs, technology, sustainability, and logistics.

Quick checklist:

- Request samples and check certifications

- Compare bulk discounts and MOQs

- Evaluate supplier reliability

- Negotiate shipping and payment terms

I recommend attending trade shows and building supplier relationships to secure the best value.

FAQ

What is the best way to verify fabric quality before buying?

I always request physical samples. I check for even weave, smooth texture, and color consistency.

Tip: Compare samples from multiple suppliers for the best results.

How do I estimate total landed cost for imported fabric?

I add fabric price, shipping, insurance, and duties.

| Cost Element | Example |

|---|---|

| Fabric | $1.05/m |

| Shipping | $0.20/m |

| Duties | $0.10/m |

Can I get custom colors or finishes for polyester rayon fabric?

Yes, I often request custom dyeing or finishing. Suppliers usually require higher minimum orders for custom work.

- Ask about lead times

- Confirm extra costs

Post time: Aug-04-2025