I see how antimicrobial technologies in healthcare fabric make a difference. These solutions stop harmful microbes from growing on surfaces like water repellent fabric, polyester viscose scrub fabric, and TR spandex scrub fabric. The results speak for themselves:

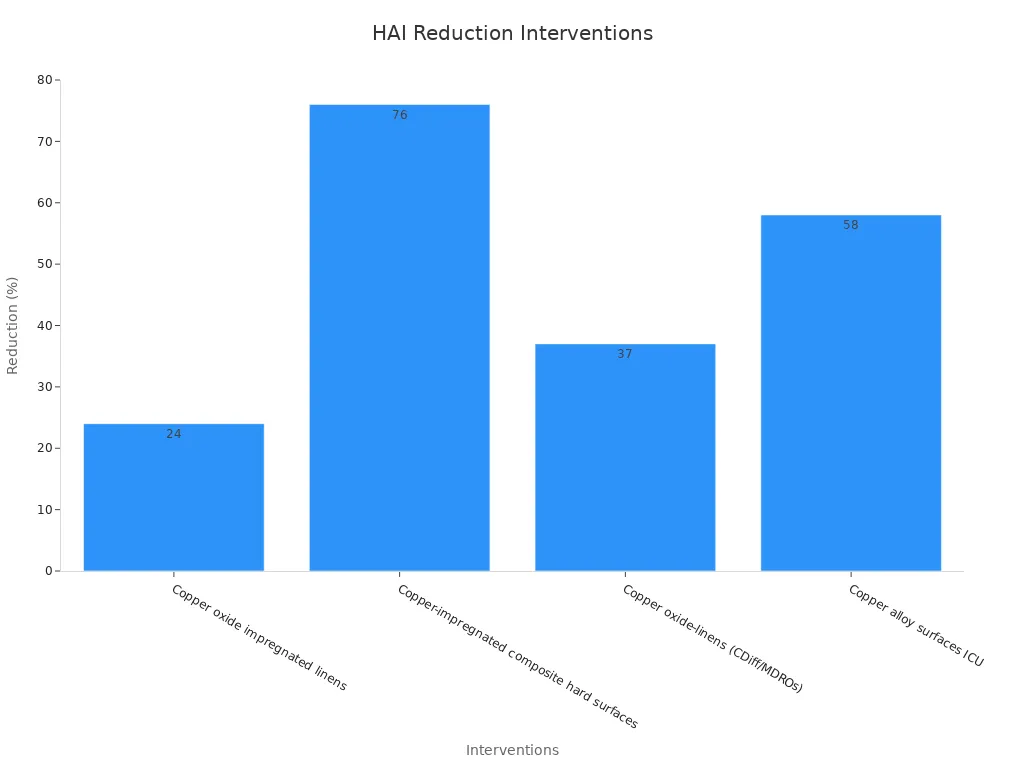

| Intervention Type | Reported Reduction | Outcome Measured |

|---|---|---|

| Copper oxide impregnated linens | 24% reduction in HAIs per 1000 hospital days | Hospital-acquired infections (HAIs) |

| Copper-impregnated composite hard surfaces and linens | 76% aggregate reduction in HAIs | Hospital-acquired infections (HAIs) |

| Copper oxide-impregnated textiles | 29% reduction in antibiotic treatment initiation events (ATIEs) | Antibiotic treatment initiation events |

| Copper-impregnated composite hard surfaces, bed linens, and patient gowns | 28% reduction in Clostridium difficile and multidrug-resistant organisms (MDROs) | Specific pathogens (C. difficile, MDROs) |

| Copper oxide-impregnated linens | 37% reduction in HAIs caused by Clostridium difficile and MDROs | Specific pathogens (C. difficile, MDROs) |

| Zinc Oxide (ZnO) nanoparticles with chitosan | 48% reduction in Staphylococcus aureus and 17% reduction in Escherichia coli | Specific pathogens (S. aureus, E. coli) |

I recommend using stretch polyester rayon hospital uniform fabric and polyester rayon four way stretch fabric to help keep medical spaces safer.

Key Takeaways

- Antimicrobial fabrics use special agents like copper, silver, and natural substances to stop harmful germs from growing on hospital clothes and bedding.

- These fabrics remain effective even after many washes and sterilizations, helping reduce infections and keep patients and staff safer.

- Using antimicrobial healthcare fabrics supports cleaner hospitals, lowers infection rates, and offers safe, skin-friendly options that protect both people and the environment.

Mechanisms and Science of Antimicrobial Healthcare Fabric

Types of Antimicrobial Agents

When I look at the science behind healthcare fabric, I see a wide range of antimicrobial agents at work. Each agent uses a unique method to stop or kill harmful microbes. Here is a table that shows the most common agents, how they work, and which fibers they treat:

| Antimicrobial Agent | Mode of Action | Typical Fibers Used |

|---|---|---|

| Chitosan | Inhibits mRNA synthesis and blocks transport of essential solutes | Cotton, Polyester, Wool |

| Metals and Metallic Salts (e.g., silver, copper, zinc oxide, titanium nanoparticles) | Generates reactive oxygen species; damages proteins, lipids, DNA | Cotton, Polyester, Nylon, Wool |

| N-halamine | Interferes with cellular enzymes and metabolic processes | Cotton, Polyester, Nylon, Wool |

| Polyhexamethylene Biguanide (PHMB) | Disrupts cell membrane integrity | Cotton, Polyester, Nylon |

| Quaternary Ammonium Compounds | Damages cell membranes, denatures proteins, inhibits DNA synthesis | Cotton, Polyester, Nylon, Wool |

| Triclosan | Blocks lipid synthesis and disrupts cell membrane | Polyester, Nylon, Polypropylene, Cellulose Acetate, Acrylic |

I often see metals like silver and copper used in hospital uniforms and bedding. These agents help reduce the spread of bacteria and viruses in healthcare fabric. Quaternary ammonium compounds and chitosan also appear in many products for both patients and healthcare professionals.

Note: Testing standards such as AATCC 100, ISO 20743, and ASTM E2149 help measure how well these agents work in real-world settings.

How Agents Disrupt Microbial Growth

I find that antimicrobial agents use several strategies to stop microbes from growing on healthcare fabric. Here are some of the main ways these agents work:

- They attack the cell walls or membranes of bacteria, causing the cells to burst or leak.

- Some agents, like silver nanoparticles, release ions that disrupt proteins and DNA inside the microbe.

- Others, such as chitosan, block the microbe’s ability to make new proteins or transport nutrients.

- Certain agents create reactive oxygen species that damage key parts of the microbe, leading to cell death.

- Enzyme-based treatments can break down the protective layers of microbes, making them easier to kill.

Laboratory tests confirm these actions. For example, I have seen studies where fabrics treated with silver or zinc oxide nanoparticles show strong activity against bacteria like E. coli and Staphylococcus aureus. Scientists use tools like scanning electron microscopy to check that these agents stay attached to the fabric and keep working after washing. Standard tests, such as those from the American Association of Textile Chemists and Colorists, help verify both the strength and durability of these treatments.

Effectiveness and Durability

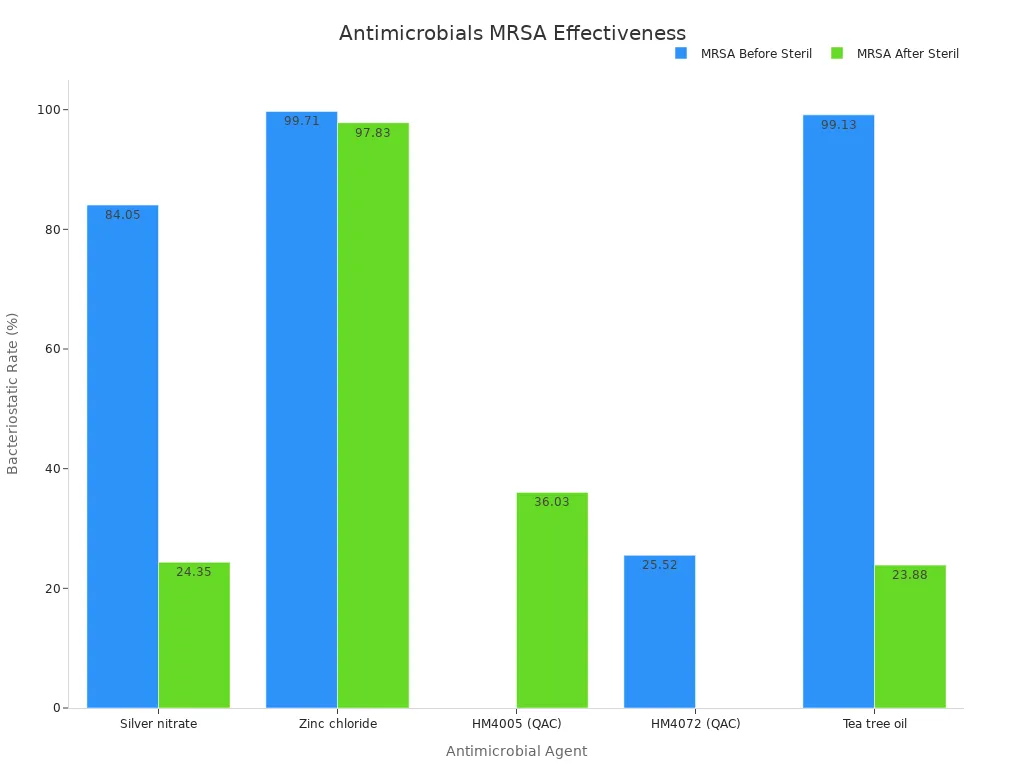

I always look for healthcare fabric that keeps working after many uses and washes. The best antimicrobial treatments show high effectiveness against a range of bacteria, even after sterilization. The table below shows how different agents perform before and after sterilization:

| Antimicrobial Agent | BR against E. coli (%) | BR against K. pneumoniae (%) | BR against MRSA (%) | BR after Sterilization against E. coli (%) | BR after Sterilization against K. pneumoniae (%) | BR after Sterilization against MRSA (%) |

|---|---|---|---|---|---|---|

| Silver nitrate | 99.87 | 100 | 84.05 | 97.67 | 100 | 24.35 |

| Zinc chloride | 99.87 | 100 | 99.71 | 99.85 | 100 | 97.83 |

| HM4005 (QAC) | 99.34 | 100 | 0 | 65.78 | 0 | 36.03 |

| HM4072 (QAC) | 72.18 | 98.35 | 25.52 | 0 | 21.48 | 0 |

| Tea tree oil | 100 | 100 | 99.13 | 100 | 97.67 | 23.88 |

I notice that zinc chloride and silver nitrate keep their antimicrobial power even after heat sterilization. Tea tree oil also works well, but some agents, like certain quaternary ammonium compounds, lose much of their effect after sterilization. Long-term studies show that coatings with copper oxide and graphene oxide can keep killing bacteria for up to six months. In one study, these treated fabrics kept over 96% effectiveness against E. coli after half a year of use.

Clinical trials back up these findings. For example, hospital pillowcases and sheets coated with antimicrobial agents kept bacterial counts below hygiene standards after a week of use. These results show that the right antimicrobial treatments can make healthcare fabric safer and more reliable for both patients and staff.

Application, Benefits, and Future of Healthcare Fabric Technologies

Integration Methods in Healthcare Fabric

I have seen several effective ways to add antimicrobial agents to healthcare fabric. These methods help keep the fabric safe and long-lasting.

- Coating techniques like dip-coating, spray-coating, and electrospinning apply agents to the fabric surface. Electrospinning creates nanofibers that boost antimicrobial action.

- Incorporation into fibers during manufacturing locks agents inside, making the fabric durable and resistant to washing.

- Finishing treatments such as plasma treatment improve how well agents stick to the fabric.

- Nano-coating technologies embed agents at the molecular level, which helps prevent leaching and keeps the fabric effective.

- Silver nanoparticles, copper ions, and quaternary ammonium compounds work well and last through many washes.

- Hospitals using these fabrics have reported fewer infections and cleaner surfaces.

- Standard tests like AATCC 100 and ISO 20743 check that these fabrics stay effective and safe.

Safety, Compliance, and Real-World Impact

I always check that healthcare fabric meets strict safety rules. These fabrics must be safe for skin, non-toxic, and sterile. They need to stop infections and avoid causing allergies. International laws and guidelines make sure these fabrics protect patients and staff.

- Plant-based agents offer safe, skin-friendly options.

- Antimicrobial finishes cut down on germs, odors, and fabric damage.

- Eco-friendly compounds lower the risk of irritation and cross-contamination.

- These fabrics help stop the spread of germs in hospitals.

Regular testing with AATCC 100 and ISO 20743 ensures that healthcare fabric keeps working over time.

Environmental Considerations and Innovations

I care about the environment when choosing healthcare fabric. Some agents can wash out and harm water systems. Using natural substances from plants gives a safer, biodegradable choice. Passive coatings that stop microbes from sticking, instead of killing them, also help protect the environment. These new ideas make healthcare fabric safer for people and the planet.

I see that antimicrobial technologies in healthcare fabric give strong protection by stopping germs from growing. Hospitals using these solutions report fewer infections. Data-driven infection control, like at Vanderbilt University Medical Center, shows real drops in infection rates. I expect new advances will keep making healthcare fabric safer and more effective.

FAQ

What makes antimicrobial healthcare fabric different from regular fabric?

I see antimicrobial fabric as special because it stops germs from growing. Regular fabric does not have this protection.

How long do antimicrobial treatments last on healthcare fabric?

I notice that many treatments last through dozens of washes. Some keep working for up to six months, depending on the agent and washing method.

Are antimicrobial fabrics safe for sensitive skin?

I always check for safety. Most healthcare fabrics use skin-friendly agents. I recommend looking for products tested for allergies and irritation.

Post time: Jun-20-2025