Pilling refers to the formation of small fiber balls on fabric surfaces caused by repeated friction during wearing, washing, or daily use. These pills are formed when loose fibers migrate to the fabric surface, entangle with one another, and gradually develop into visible fuzz or balls that cannot be easily removed without damaging the fabric.

Although pilling does not usually compromise the structural strength of a fabric, it seriously affects appearance, perceived quality, and the usable lifespan of a garment. In many consumer markets, a garment is often judged as “old” or “low quality” not because it is worn out, but because it looks worn out due to surface pilling.

This issue is particularly critical in suiting, medical wear, uniforms, and corporate apparel, where a clean, professional appearance is essential. Even minor pilling on sleeves, collars, or high-friction areas such as underarms, seat panels, and cuffs can quickly lead to customer complaints, returns, or failed quality inspections. As a result, pilling resistance is frequently a key rejection factor during fabric evaluation and bulk approval.

Another challenge is that pilling often develops after the garment reaches the end user, making it difficult to correct once production is completed. This is why anti-pilling performance must be evaluated and controlled at the fabric stage, rather than addressed reactively after market feedback.

Main Pilling Test Methods

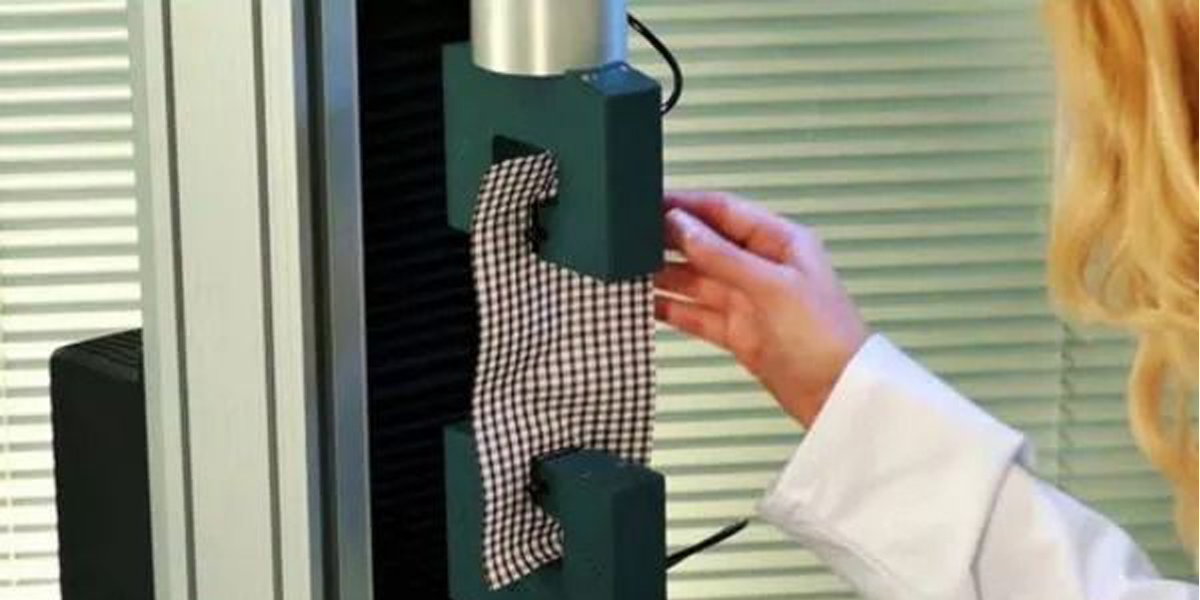

To objectively evaluate pilling resistance, several standardized test methods are commonly used in the textile industry. Each method simulates a different type of real-life wear condition.

Martindale Method (ISO 12945-2)

The Martindale method simulates fabric-to-fabric abrasion under controlled pressure and movement. Circular specimens are rubbed against a standard fabric in a Lissajous motion for a specified number of cycles.

This method is widely used for:

-

Suiting fabrics

-

Uniform fabrics

-

Medical and workwear textiles

It provides stable, repeatable results and is often preferred for woven fabrics that require higher appearance standards.

Random Tumble Pilling (ASTM D3512)

The Random Tumble Pilling test simulates real wear through random agitation inside a rotating chamber. Fabric samples are tumbled with cork liners, creating multidirectional friction.

This method is especially suitable for:

-

Casual wear fabrics

-

Softer fabrics with raised surfaces

-

Fabrics prone to fuzz formation

Because the motion is less controlled, this test often produces more aggressive and realistic pilling results.

Box Method (ISO 12945-1)

The Box method simulates mild rubbing and early-stage wear by tumbling fabric specimens inside a cork-lined box.

It is typically used for:

-

Fabrics with lower abrasion exposure

-

Comparative evaluations

-

Development-stage testing

While less severe than Martindale, it is useful for identifying early pilling tendencies.

Rating System

After testing, fabrics are visually evaluated and rated against standardized photographic references.

-

Grade 5: No visible pilling

-

Grade 4: Slight pilling

-

Grade 3: Moderate pilling

-

Grade 1–2: Severe pilling

Most commercial apparel programs require:

Grade ≥3.5 after 5,000 cycles

For medical garments, uniforms, and corporate wear, requirements are usually stricter:

Grade ≥4 is commonly expected to ensure long-term appearance retention.

It is important to note that ratings should be performed under standardized lighting conditions and by trained inspectors to minimize subjectivity.

Factors Affecting Pilling

Pilling performance is influenced by a combination of fiber, yarn, fabric structure, and finishing factors.

Key contributors include:

-

Fiber length and fineness: Short fibers are more likely to migrate and pill

-

Yarn twist: Lower twist increases softness but raises pilling risk

-

Fabric structure: Looser constructions tend to pill more easily

-

Finishing processes: Certain finishes can either reduce or increase surface fuzz

-

Fiber blends (e.g. poly-viscose, poly-spandex): Blends may trap broken fibers on the surface

For example:

-

Low twist yarn → Softer handfeel but higher pilling risk

-

Brushing or sanding → Comfort increases, but surface fibers become more exposed, reducing pilling resistance

Understanding these trade-offs is critical when designing fabrics for both comfort and durability.

How Manufacturers Improve Anti-Pilling Performance

From a manufacturing perspective, several techniques can be applied to improve pilling resistance:

-

Increasing yarn twist to reduce loose fibers

-

Singeing to remove surface fuzz

-

Enzyme treatment to clean protruding fibers

-

Resin finishing to bind surface fibers

-

Structural optimization of weave or knit design

However, it is important to note that over-finishing may improve pilling resistance at the expense of softness, breathability, or drape. Excessive resin use, for example, may lead to a stiff handfeel or reduced comfort.

Effective anti-pilling control requires a balanced approach, aligning fabric performance with the intended application and market positioning.

Buyer Checklist for Anti-Pilling Control

For buyers and brands, proper pilling control goes beyond reviewing a single test report.

✔ Test fabrics before and after finishing

✔ Evaluate pilling performance after washing

✔ Assess both appearance and handfeel, not just ratings

✔ Confirm batch-to-batch consistency in bulk production

This approach helps reduce post-delivery risks and ensures that approved samples accurately represent bulk performance.

Conclusion

Pilling resistance is a silent quality killer that directly impacts customer satisfaction and brand perception.

Brands that proactively control pilling performance from the fabric stage — through proper testing, engineering, and quality control — gain a clear advantage in long-term product quality and customer loyalty.

Post time: Jan-28-2026