As a custom uniforms manufacturer, I prioritize premium materials and expert craftsmanship to deliver custom uniforms that stand the test of time. Serving as both a fabric supplier with garment service and a workwear fabric supplier, I ensure every piece—whether made from medical uniforms fabric or designed as custom shirts—provides unmatched comfort, durability, and style. As a custom shirt manufacturer, I understand how superior quality enhances customer satisfaction.

- Using premium materials from a trusted workwear fabric supplier increases comfort and durability, encouraging repeat business.

- Custom uniforms not only foster team spirit but also effectively showcase a strong brand image.

Key Takeaways

- Choose high-quality fabrics like cotton, linen, or blends to make uniforms comfortable, durable, and suitable for different climates.

- Involve employees in the design process to create uniforms that fit well, look professional, and boost team satisfaction.

- Trust expert tailoring and careful quality checks to ensure uniforms last longer, maintain their shape, and support your brand image.

Transforming Quality Fabrics into Custom Uniforms

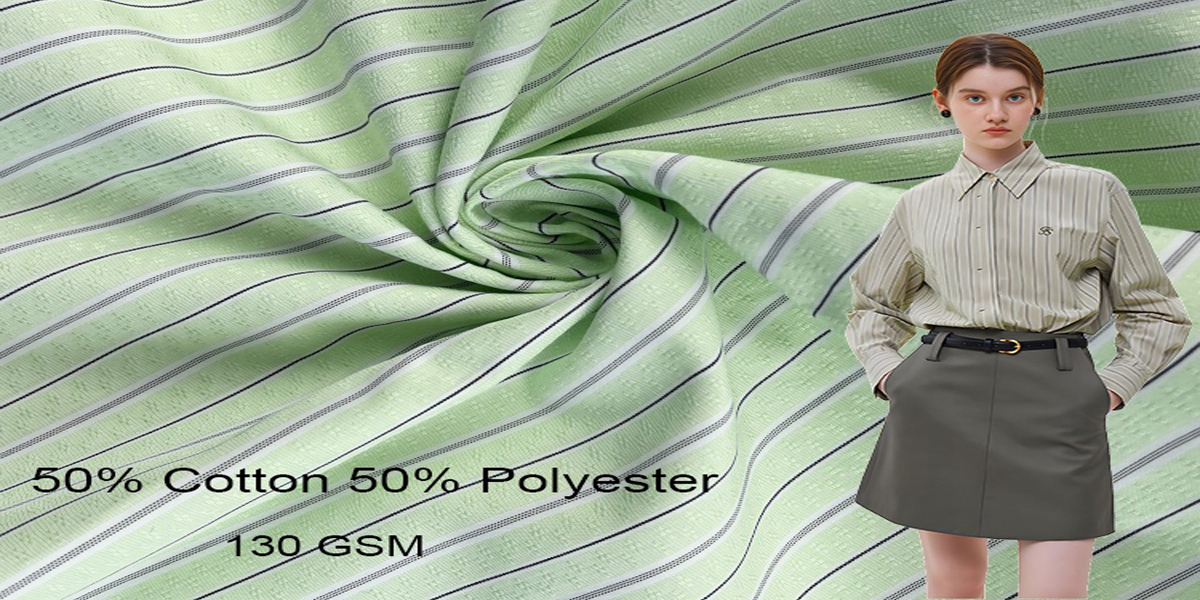

Selecting Premium Fabrics for Custom Uniforms

When I start a new project, I always focus on choosing the right fabric. The fabric sets the foundation for every uniform I create. I look for materials that offer comfort, durability, and a professional appearance. To help you understand the differences, here is a table showing the most common premium fabrics I use and their unique features:

| Fabric Type | Distinguishing Features |

|---|---|

| Cotton | Breathable, easy to maintain, holds dye well, practical, and cost-effective. |

| Linen | Lightweight, quick to dry, smooth luster, ideal for hot climates, less stiff than cotton. |

| Silk | Natural sheen, smooth texture, lighter than cotton, luxurious, excellent drape, but less durable. |

| Wool | Warm, durable, heavier, mainly for sweaters, can be custom tailored. |

| Natural Fiber Blends | Cotton-linen blends are lighter and less stiff; cotton-wool blends are rare and low-cost. |

| Synthetic Fibers | Small blends add durability and mildew resistance; too much makes fabric stiff and less breathable. |

I select each fabric based on the needs of the client. For example, cotton works well for everyday uniforms because it is comfortable and easy to care for. Linen is perfect for uniforms in hot climates. Silk adds a touch of luxury for special occasions. I avoid using too much synthetic fiber because it can make uniforms uncomfortable.

Sourcing, Inspection, and Fabric Preparation

I take sourcing very seriously. I only work with suppliers who meet strict industry standards. These include certifications like ISO 9001 for quality management, ISO 14001 for environmental responsibility, and OEKO-TEX Standard 100 for textile safety. For safety uniforms, I check for EN ISO 20471 compliance. I also look for ethical sourcing certifications such as BSCI or WRAP. Before I accept any fabric, I ask for scanned certificates with QR codes or serial numbers. Sometimes, I request third-party audit reports or even factory tours to confirm compliance.

Once I receive the fabric, I inspect it for defects and test its properties. I check for breathability, durability, and colorfastness. Breathable fabrics keep workers comfortable during long shifts. Durable fabrics help uniforms last longer and reduce replacement costs. Colorfastness ensures the uniform looks good even after many washes. I also make sure the fabric works well with customization methods like embroidery or screen printing.

Fabric preparation is another key step. I use pre-shrinking to make sure the fabric keeps its shape after washing. I pay close attention to dyeing processes, such as mercerization, which improves luster and strength. I always make sure to remove any alkali residues from pre-treatment and dyeing. If not removed, these residues can cause fading and defects later. I use controlled pH conditions during post-finishing to ensure color-fixing agents and softeners work properly. This careful preparation helps me deliver Custom Uniforms that look sharp and last longer.

Tip: Proper fabric preparation prevents long-term issues like fading and shrinkage, ensuring your uniforms maintain their quality and appearance.

Why Fabric Quality Is Essential for Custom Uniforms

I believe fabric quality is the most important factor in making Custom Uniforms. High-quality fabrics make uniforms more comfortable and durable. They also help uniforms keep their color and shape over time. When I choose better fabrics, I see a clear return on investment for my clients. Uniforms made from premium materials last longer, which means fewer replacements and lower costs in the long run.

Businesses often measure the value of quality uniforms by tracking costs, employee satisfaction, and brand image. Comfortable uniforms improve team morale and reduce turnover. Durable uniforms save money by lasting longer. Uniforms that look good help build a strong brand and make a positive impression on customers.

I also face challenges in the process. Meeting strict safety and quality standards can increase production complexity. I must balance innovation, like using eco-friendly fabrics, with cost efficiency. Supply chain disruptions and new technologies require me to stay flexible and keep learning. Despite these challenges, I always focus on delivering the best possible product.

Choosing high-quality fabrics for Custom Uniforms is not just about appearance. It is a smart investment that supports your brand, your team, and your bottom line.

Design, Tailoring, and Finishing for Custom Uniforms and Shirts

Consultation and Custom Design Options

When I begin a new project, I always start with a thorough consultation. I meet with clients to understand their needs, brand identity, and the specific roles of their team members. I involve employees, department heads, and management in the decision-making process. This helps me make sure the uniforms meet everyone’s needs. I often use surveys to gather feedback about design preferences, comfort, and functionality. Fitting sessions allow employees to try on samples and share their thoughts on fit and comfort. This feedback loop helps me improve the uniforms over time.

Clients often request a wide range of custom design options. Here are some of the most popular choices:

- Selection of base styles, colors, and fabrics

- Choice of trims, embroidery, buttons, and pocket styles

- Customization for luxury hospitality uniforms, such as those for hotels and resorts

- Flexibility to collaborate with in-house designers or use my full design services

- Replicating existing uniform programs or creating new, high-end designs

- Providing samples and fabric swatches for decision-making

- Supporting a wide range of styles beyond what is shown online

For apparel items, clients frequently choose t-shirts, polo shirts, jackets, hoodies, and beanies. They often want to add logos, graphics, or photos using embroidery or printing. Many clients use my online design studio to preview and adjust their designs before placing an order. This process ensures satisfaction and reduces errors.

Tip: Involving employees in the design process increases satisfaction and ensures the uniforms are comfortable and functional.

Pattern Making and Precision Cutting

After finalizing the design, I move to pattern making. I use advanced software to create precise patterns for each garment. This technology helps me achieve a perfect fit and reduces fabric waste. Here is a table showing some of the top software tools I use:

| Software | Key Features |

|---|---|

| Gerber AccuMark | Industry-standard pattern making, grading, marker making, fabric simulation, PLM integration, waste reduction |

| Lectra | 2D/3D pattern making, advanced grading, automated marker making, PLM integration |

| TUKAcad | User-friendly, 3D garment visualization |

| PolyPattern | Accurate 2D/3D pattern making, grading, integration with other design software |

| Optitex | Advanced 2D/3D pattern making, virtual prototyping, fabric simulation, automated nesting |

| PatternSmith | Easy to use, 2D/3D pattern making, grading, CAD integration |

| Browzwear | 3D garment visualization, pattern creation/editing, fabric simulation, virtual fitting/sizing |

| Marvelous Designer | Realistic 3D garment simulation, pattern creation/editing, advanced draping and fitting tools |

These tools allow me to visualize garments in 3D, simulate fabric behavior, and make adjustments before cutting any material. I can quickly adapt patterns for different body types and job roles. This precision ensures that Custom Uniforms fit well and look professional.

Expert Tailoring, Assembly, and Quality Control

Once I have the patterns, I begin the tailoring and assembly process. My team includes expert tailors with years of experience and specialized training. Many hold technical certificates or have completed apprenticeships in fields like fashion design, sewing, and textiles. Some have finished master custom designer programs that cover measuring, fitting, styling, and fabric knowledge.

| Qualification/Training Type | Description |

|---|---|

| Formal Education | High school diploma, technical certificates, associate’s or bachelor’s degrees |

| Fields of Study | Fashion design, sewing, textiles |

| Training Programs | Basic to advanced stitching, pattern drawing, textiles |

| Specialized Courses | Master custom designer programs (e.g., CTDA 7-course program) |

| Apprenticeships | Hands-on experience, industry-recognized, U.S. Department of Labor approved |

My tailors use both traditional techniques and modern machinery. They assemble each garment with care, paying attention to every detail. I conduct quality control checks at every stage. I look for issues with stitching, fit, and finish. I also test for durability and comfort, making sure the uniforms can withstand daily wear and frequent washing. I use feedback from clients to improve my process and address any concerns about softness, flexibility, or breathability.

Note: I always prioritize comfort and durability. This focus leads to higher employee satisfaction and fewer uniform replacements.

Finishing Touches, Packaging, and Delivery

After assembly, I add the finishing touches. I press and inspect each garment to ensure it meets my standards. I add custom labels, tags, and any final branding elements. For packaging, I use sturdy cardboard boxes for larger orders and custom poly mailers for smaller shipments. I choose packaging materials with high tensile strength and tear resistance to protect the uniforms during shipping. I also select lightweight and eco-friendly materials, such as recyclable cardboard and recycled plastics, to reduce environmental impact.

To enhance the unboxing experience, I include printed tissue paper, ribbons, stickers, and branded labels. I consider technical specifications like GSM (paper weight) and microns (plastic thickness) to balance durability and appearance. I use finishing techniques such as varnish, UV coating, and embossing to protect the packaging and make it visually appealing.

I coordinate delivery to ensure uniforms arrive on time and in perfect condition. I use smart logistics and real-time tracking to keep clients informed. My integrated process streamlines production, reduces errors, and ensures consistent quality from start to finish.

Post time: Aug-29-2025