The global healthcare fabrics market projects significant growth, reaching an estimated $28.19 billion in 2026 with a 12.6% CAGR. This expansion underscores the non-negotiable role of specific fabric characteristics in future healthcare environments. Critical attributes like antimicrobial properties and enhanced durability define essential healthcare fabrics. Materials such as Polyester rayon spandex, Polyester spandex, and bamboo polyester spandex offer the performance and comfort required.

Key Takeaways

- Healthcare fabrics must keep patients comfortable and help them heal. They use soft, breathable materials that control temperature and are gentle on the skin.

- Fabrics in healthcare settings must protect against germs and fluids. They have special features to stop infections and meet strict safety rules.

- Modern healthcare fabrics are strong, easy to clean, and good for the environment. They last a long time and help reduce waste.

Patient-Centric Essential Healthcare Fabrics

Healthcare facilities prioritize patient well-being. Fabrics directly touching patients must offer superior comfort and support. These essential characteristics significantly influence recovery and overall satisfaction.

Enhanced Comfort and Breathability

Patient comfort directly impacts their recovery and overall experience. Soft, breathable, and well-fitting linens reduce skin irritation, improving the well-being of bedridden patients. High-quality fabrics contribute to enhanced comfort and minimize the risk of skin irritation or infections. Breathable fabrics allow proper airflow, helping regulate temperature and moisture, which further enhances patient comfort. When patients feel comfortable, they relax more easily. This positively affects their recovery and satisfaction with their care experience. Premium, breathable fabrics allow for better airflow, keeping patients cool and comfortable. Properly sized bedding prevents wrinkles and bunching, which can increase pressure points and the risk of bedsores.

Next-generation medical textiles utilize lightweight microfiber polyester. This material offers high breathability with a moisture permeability (RET) of 2.54 and rapid drying capabilities. Such features enhance comfort for healthcare professionals and patients alike. Fabric technologies like hollow fiber construction provide insulation while remaining lightweight and breathable. Microfiber engineering uses ultra-fine fibers to increase surface area for improved moisture management and maintain fabric softness. Bio-component fibers combine different polymer components, offering multiple performance characteristics within a single fiber system. Smart fiber integration includes temperature-responsive fibers that adjust breathability based on environmental conditions.

Advanced manufacturing techniques create 3D fabric structures. These structures optimize enhanced air circulation and effective moisture management, contributing to improved comfort and breathability. Techniques such as laser perforation create precise micro-holes to increase air permeability without compromising fabric strength. Mechanical stretching opens the fabric structure to improve air circulation while maintaining dimensional stability. Surface treatments like brushing and raising increase the fabric’s air-trapping capacity and enhance moisture-wicking through an increased surface area. Moisture-wicking finishes improve moisture transport away from the skin. Anti-microbial treatments prevent bacterial growth, maintaining fabric freshness and hygiene while preserving breathability. Phase Change Materials (PCM) absorb, store, and release heat to maintain optimal temperature regulation. Specialized cooling finishes provide cooling sensations through enhanced evaporation or endothermic reactions.

Skin Compatibility and Softness

Fabrics in healthcare settings must be gentle on the skin, especially for vulnerable patients. Dermatological standards and certifications ensure textiles meet strict safety criteria. ISO 10993 provides biological evaluation for medical textiles, including cytotoxicity, sensitization, and irritation modules. This standard applies to hospital gowns, wound dressings, and PPE fabrics. The OEKO-TEX® Standard 100 is a global benchmark for harmful substance limits, covering over 100 regulated chemicals. It ensures textiles are free from toxic residues for prolonged skin contact. REACH (EU) is a European Union chemical regulation covering over 2,000 restricted substances, mandatory for any textile imported into the EU. Dermatological patch testing, including Human Repeat Insult Patch Test (HRIPT), assesses real-world skin responses like redness, itching, or eczema flare-ups. This confirms user safety beyond chemical analysis. In-vitro tests use reconstructed human epidermis (RHE) to model skin response, reducing reliance on large volunteer trials.

Specific fabric treatments and materials improve skin compatibility and softness. Viscose and algae composite fibers offer a soft skin feel. They also provide natural vitamins, micronutrients, and elements, with tested antioxidant capacity when worn next to the skin. Vitamin-encapsulated fibers, particularly Vitamin E, offer bioactive properties, antioxidant effects, and potential aid in wound healing. These fibers integrate into textiles through microencapsulation for anti-aging and moisturizing properties. Polyester fabrics with hydrophilic surface finishes, capillary yarn structures, and dual-layer designs improve comfort and skin compatibility by effectively managing moisture and keeping the skin dry. Silicone coatings apply to polyester for a soft touch. Products like SOFTWICK™ SF30, a silicone-free hydrophilic finishing treatment, combine softness and wicking in a single application. This is ideal for medical nonwovens like surgical gowns and drapes, providing permanent hydrophilicity without migration and superior fluid distribution. GENFLO™ 5055, a polymer binder, offers a good balance of soft feel and tensile strength.

Temperature Regulation and Flexibility

Maintaining optimal patient temperature is crucial for comfort and recovery. Healthcare zones have specific temperature ranges. Operating rooms, endoscopy suites, and clean workrooms typically maintain 68 °F to 73 °F (20 °C to 23 °C). Patient rooms and delivery rooms often target 75 °F (24 °C). Most other healthcare zones range from 70 °F to 75 °F (21 °C to 24 °C). Patients generally exhibit less sensitivity to thermal environments compared to staff, often accepting a broader range of temperatures. Personalized temperature control helps healthcare providers tailor the environment to individual patient preferences, enhancing satisfaction. Proper temperatures ease discomfort from treatments or medication side effects. Regulating room temperature, ideally between 60 to 68 degrees Fahrenheit for sleep, supports better rest, vital for healing and immune function. Avoiding temperature extremes prevents negative impacts on patient health.

Advanced fabric technologies provide temperature regulation and flexibility. Shape memory textiles, such as NiTi-based shape memory alloys, offer properties like shape memory, high deformation recovery, and flexibility. They adapt to external conditions like temperature, allowing for dynamic garment fitting and thermo-responsive behavior. Smart temperature control textiles include cool textiles, automatic temperature control textiles, and thermal insulation textiles. Cool fabrics often incorporate metal oxides into polyester to maintain a cool interior. Thermal insulation fabrics use materials like solar thermal storage fibers and far-infrared fibers. Graphene infrared textiles provide thermal regulation and sensing capabilities. They feature tunable emissivity and adaptive insulation, allowing for adaptive thermal management and real-time temperature sensing. Phase-change technology, like Outlast Adaptive Comfort®, helps maintain a consistent body temperature, enhancing comfort by adapting to the wearer’s demands. Smart textiles monitor physiological signals such as body temperature, heart rate, and movement, aiding in patient monitoring and rehabilitation. Intelligent textiles with integrated heating or cooling components assist in controlling body temperature, improving comfort.

Fabric choice significantly impacts sleep quality and patient well-being. Merino wool significantly reduces wakefulness after sleep onset (WASO) and increases total sleep time (TST) compared to cotton and polyester. Participants reported feeling “more comfortable” and “less hot” in merino wool. In contrast, cotton and polyester led to higher WASO, lower TST, and lower sleep efficiency. Merino wool maintained better sleep quality in both hot (27°C) and cold (17°C) conditions compared to cotton and polyester. It demonstrated superior thermoregulatory properties, dissipating heat more effectively in hot conditions and providing better insulation in cold conditions. Merino wool led to more stable skin temperatures and lower, more stable heart rates. Participants consistently reported more neutral thermal sensations and higher overall comfort with merino wool across all temperatures. These findings highlight the critical role of advanced healthcare fabrics in optimizing patient outcomes.

Safety and Infection Control in Healthcare Fabrics

Healthcare environments demand robust protection against pathogens and fluids. Fabrics must act as impenetrable barriers. This prevents the spread of infection. Regulatory standards ensure these materials meet stringent safety criteria.

Superior Barrier Protection and Fluid Resistance

Different levels of protection exist for medical fabrics. These levels depend on the intended use. Test methods evaluate resistance to various liquids.

| Level | Test Method | Liquid Challenge | Expected Barrier Effectiveness |

|---|---|---|---|

| 1 | AATCC 42 Impact Penetration | Water | Minimal water resistance (some resistance to water spray) |

| 2 | AATCC 42 Impact Penetration, AATCC 127 Hydrostatic Pressure | Water | Low water resistance (resistant to water spray and some resistance to water penetration under constant contact with increasing pressure) |

| 3 | AATCC 42 Impact Penetration, AATCC 127 Hydrostatic Pressure | Water | Moderate water resistance (resistant to water spray and some resistance to water penetration under constant contact with increasing pressure) |

| 4 | ASTM F1670 Synthetic Blood Penetration Test, ASTM F1671 Viral Penetration Test | Surrogate Blood, Bacteriophage Phi-X174 | Blood and viral penetration resistance (2 psi) |

Level 4 fabrics are impermeable to viral penetration. They undergo specific testing for viral resistance using synthetic blood and bacteriophage Phi-X174.

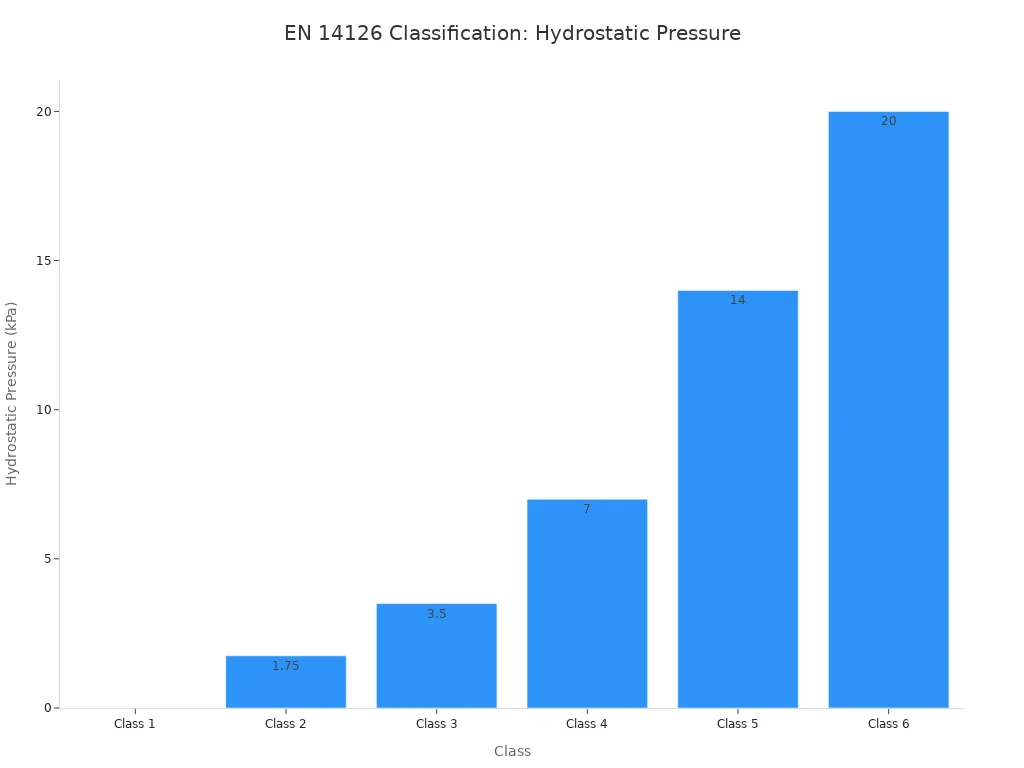

EN 14126 classifies materials based on their resistance to penetration by blood and body fluids. This standard uses ISO 16603 and ISO 16604 test methods.

| Class | Hydrostatic pressure at which material passes the test (kPa) |

|---|---|

| 6 | 20 |

| 5 | 14 |

| 4 | 7 |

| 3 | 3.5 |

| 2 | 1.75 |

| 1 | 0 |

Other critical standards include:

- ANSI/AAMI PB 70:12: This standard classifies barrier performance for surgical gowns, protective apparel, and drapes.

- NFPA 1999: This standard addresses protective clothing for emergency medical operations. It includes design, performance, labeling, and test methods like ASTM F1671 for viral penetration.

- EN 13795: This standard describes barrier test methodologies for surgical gowns. It focuses on patient protection.

Specialized fabric technologies provide superior barrier protection.

- UltraFlex™: Barrier Technologies developed this medical-grade, urethane-coated fabric. It is impervious to fluids. Healthcare staff easily clean it with disinfectants. It also resists stains, offers comfort, and has antibacterial properties. This helps prevent hospital-acquired infections.

- HYDRO-TEX + VIRUSHIELD 1030: Impermea Materials offers this superhydrophobic coating technology. It transforms conventional textiles into breathable, superhydrophobic barriers. This coating repels larger droplets. It also traps smaller droplets containing active viruses. This prevents their transmission through protected surfaces. The formula is water-based and PFAS-free. It maintains the fabric’s feel and breathability.

- Tex Tech Industries offers various coating and lamination capabilities. These include silicone-coated fabrics. They enhance barrier protection.

- Sure-Chek® fabrics: Herculite’s healthcare fabrics incorporate a proprietary antimicrobial additive. This additive protects the fabric from microbial attack. It also reduces undesirable organic odors. All Sure-Chek® healthcare fabrics resist fluid and moisture. This helps reduce contamination risk for mattress interiors.

Integrated Antimicrobial Properties

Antimicrobial properties in fabrics are essential for infection control. They actively reduce microbial growth. This minimizes the risk of pathogen transmission.

Various effective antimicrobial agents and technologies integrate into healthcare fabrics.

- Synthetic Agents: Silver nanoparticles and copper compounds are widely used. They offer broad-spectrum antimicrobial properties. Copper-embedded fabrics maintain efficacy even after many washes.

- Natural Agents: Chitosan, plant-based polyphenols, and tannic acid are gaining popularity. They are biodegradable and environmentally safe. Cotton treated with propolis shows superior antibacterial performance. Pterostilbene grafted onto chitosan provides 99.9% antibacterial activity.

- Advanced Technologies:

- Layer-by-Layer (LbL) assembly provides uniform and long-lasting protection. For example, polylysine-chitosan works against S. aureus and E. coli.

- Embedding agents into masterbatches enhances durability. Cuprous oxide nanoparticles are an example.

- The sol-gel process integrates biocidal agents like silver or copper.

- Direct generation of Metal-Organic Frameworks (MOFs) like ZIF-8 offers exceptional hydrophobicity and mechanical strength.

- Metal-Free, Particle-Free Solutions: Innovations like Sanitized Puretec are effective on all fiber types. They are non-leaching and metal-free. Microban’s Ascera is nature-inspired and metal-free. It works for olefinic polymers and solvent-based coatings. These offer sustainable, lower-toxicity alternatives.

Antimicrobial agents in healthcare fabrics effectively combat a range of pathogens. These include S. aureus, E. coli, MRSA, and VRE. Fabrics treated with polylysine-chitosan via LbL assembly show up to 99.9% antibacterial activity against S. aureus and E. coli. In clinical settings, antimicrobial fabrics significantly reduce the growth of harmful pathogens. These fabrics are used in scrubs, hospital linens, and protective clothing. They often incorporate agents like zinc pyrithione, hydrophilic fluorocarbon resin, copper oxide, or copper composites. They contribute to reducing hospital-acquired infections (HAIs), fevers, and antibiotic usage.

Antimicrobial-impregnated fabrics prevent or inhibit microbial growth. They also prevent biofilm formation and microbial propagation. This reduces infection sources in healthcare settings. Copper oxide and silver nanoparticles are key antimicrobial substances. These fabrics are more effective when patients use them (e.g., bed linens, clothing). Their efficacy for healthcare workers’ uniforms requires further research. These textiles help break infection chains. They reduce microbial load on surfaces and fabrics. This lowers transmission risk, including for multidrug-resistant strains. They limit the spread of pathogenic bacteria and viruses, such as multidrug-resistant strains and viral threats like COVID-19.

Fire Retardancy and Stain Resistance

Fire safety and stain resistance are critical for healthcare environments. They ensure patient safety and maintain hygiene.

Fire safety standards and regulations for textiles are strict.

- California’s TB 116 and TB 117: These standards test how fabrics react to flames and smoldering. They apply particularly to upholstered seating in public areas of healthcare facilities.

- NFPA 101 Life Safety Code: This code establishes comprehensive fire safety requirements for healthcare furnishings. It aims to slow flame spread and reduce ignition risk. This is especially important where vulnerable patients cannot evacuate quickly.

Textile fire testing focuses on several aspects:

- Ignition Sensitivity and Fire Spread Speed: These are primary focuses. Tests often use small flames or burning cigarettes as ignition sources.

- Formation of Harmful Gases and Smoke: Testers measure these in addition to ignition sensitivity and fire spread.

- Other Fire Behavior: This includes heat release, dripping, melting, or sparking of the material.

International and national standards guide these tests. Examples include ISO 12952 for bedding items, EN 1021 for upholstered furniture, and EN 1102 for curtains and drapes.

Hospital furniture uses flame-resistant materials. Fabrics and foams in hospital chairs and mattresses are specially treated. They meet strict flammability tests. Fire-safe construction ensures frames and plastics are inherently flame-retardant. This contains heat and flames during a fire. Even waiting-room sofas must meet these fire-safety standards. This ensures they do not become fuel in an emergency.

Fabrics in healthcare settings also face frequent staining. Different fabric types offer varying resistance.

- Nylon: This fabric is fairly heat resistant. Common alkalies do not affect it. It resists most diluted bleaches.

- Polyester: This fabric is strong and abrasion-resistant. It is dimensionally stable. It offers excellent spotting and cleaning results. However, it attracts oily soils and may yellow.

- Acrylic: This fabric has moderate abrasion resistance. It resists both water- and oil-based staining agents. It is extremely colorfast and resists acids.

- Olefin (Polypropylene): This fabric attracts oily soils (it may yellow). It resists fungi and is chemically inert. It offers excellent resistance to alkalies and acids. It bleaches safely with sodium hypochlorite solutions.

- Colorfastness: Fabrics for healthcare use should be coded W or W-S. This means they are stable to water-based or dry solvent-based spotters/cleaners.

Fabric color and composition significantly impact stain concealment.

| Stain Type | Problem/Characteristics | Best Fabric Color/Strategy | Why it Works |

|---|---|---|---|

| Blood | Reddish tones, stand out on light colors | Navy blue, dark green, subtle prints/textures | Dark, cool tones mask reddish hues; patterns camouflage splashes |

| Disinfectants (e.g., povidone-iodine) | Brown/reddish, can stain fabric | Navy blue, dark gray, black | Deep, highly pigmented colors reduce contrast with brown/yellow tints |

| Alcohol, Clear Solutions, Chlorhexidine | Residue alters texture/shine, causes lightening | Medium gray, navy blue | Medium tones conceal brightness differences/discoloration; dark colors soften bleaching |

| Sweat | Noticeable moisture depending on fabric color/composition | Black, charcoal gray, navy blue | Dark colors reduce appearance of dampness; medium gray disguises older stains |

| Food and Beverages (e.g., coffee, sauces) | Brown, reddish, yellowish pigments, often leave halos | Navy blue, dark gray, discreet prints, stain-resistant treatment | Dark colors reduce contrast; small patterns visually break up stains; treatments prevent setting |

Dark colors, especially navy blue, dark green, and dark gray, generally conceal blood, disinfectants, sweat, and food stains best. Discreet patterns or textured fabrics hide small stains better than plain fabrics. Proper washing and drying routines prevent stains from setting. Fabric composition (polyester versus cotton) and stain-resistant finishes significantly impact resistance. Fluid-resistant fabrics repel liquids. This adds protection against spills. Stain-resistant finishes make fabrics easier to clean and maintain. They prevent stains from setting. Some performance fabrics include antimicrobial finishes. These help prevent mold, mildew, and odors. This is especially beneficial in healthcare settings.

Sustainable and Durable Healthcare Fabrics

Healthcare facilities increasingly demand textiles that perform well and last long. These fabrics must also align with environmental responsibility. Sustainable and durable healthcare fabrics offer significant benefits. They reduce operational costs and minimize environmental impact.

Extreme Durability and Longevity

Healthcare textiles face constant use, frequent laundering, and harsh sterilization processes. Therefore, they must maintain their protective qualities over time. Industry benchmarks ensure these fabrics meet rigorous standards for durability.

| Parameter Tested | After 50 Wash Cycles | Standard Requirement |

|---|---|---|

| Hydrostatic Pressure (HSP) | 65 cm H₂O | ≥ 50 cm H₂O (AATCC 127) |

| Viral Penetration Resistance | Pass | ASTM F1671 |

| Antimicrobial Efficacy | 98.5% | ISO 20743 ≥ 99% reduction |

Fabrics must maintain barrier effectiveness even after extensive use. Multi-standard compliance is crucial. This includes standards like ISO 20743, ASTM F1670/F1671, and EN 13795. These standards ensure fabrics withstand repeated laundering, sterilization, and extreme surgical environments. Reusable gowns and garments often undergo 75–100 wash and sterilization cycles. Fabrics must retain protective features after these repeated processes. Comprehensive testing under real-use conditions provides an accurate picture of long-term durability. This bridges the gap between lab results and clinical performance.

The “reprocessing life” of healthcare textiles significantly influences their Total Cost of Ownership (TCO). Fabrics designed to withstand multiple sterilization cycles reduce replacement frequency. This lowers long-term operational costs. This durability, combined with comfort and breathability, ensures better compliance with safety protocols. It also contributes to the overall longevity and economic viability of reusable healthcare fabrics.

Specific fabric constructions enhance extreme durability.

- Unsaturated polyester resins (UPRs) combined with fiberglass create durable composites. These composites are corrosion-resistant and high-strength.

- Polyester’s chemical structure, with ester functional groups, provides strength and flexibility. It also resists degradation.

- Polylit panels, made from UV-stabilized polyester resin, offer impact resistance. They maintain structural integrity and optical clarity even in demanding outdoor environments.

Ease of Cleaning and Maintenance

Efficient cleaning and low maintenance are vital for healthcare fabrics. These properties help maintain hygiene and reduce operational costs. Certain fabric characteristics make cleaning easier.

- Non-porous surfaces: Medical-grade vinyl offers a seamless, non-porous surface. This surface is easy to clean and resists scuffs and stains. Its durability and reduced maintenance needs make it a cost-effective choice.

- Antimicrobial properties: Fabrics engineered at a molecular level resist bacterial growth. This makes them ideal for sterile environments and easier to maintain sterility.

- High abrasion resistance: This property contributes to material durability. It ensures longevity and reduces wear and tear in high-traffic areas.

- Stain resistance: Fabrics resist common substances like grease, oils, and biological contaminants. This allows for easy cleanup with mild soap and water. This is crucial for maintenance and product longevity.

- Antistatic properties: These properties prevent static electrical charges. Static can be a danger to patients and sensitive medical equipment.

- Odor resistance: Fabrics treated to resist odor-causing bacteria complement frequent washing.

- Durability: Strong fabrics resist tearing and withstand frequent washing and intense use. This maximizes textile life and reduces replacement costs.

- Antimicrobial properties: These are critical for preventing infection spread. Controlled-release antimicrobial agents are designed to last the textile’s working life.

Disposable textile systems also offer significant maintenance advantages.

- Speed and ease of use: Environmental hygiene staff can quickly swap out soiled items. This reduces room turnover time. It also eliminates the need for complex restocking or tracking.

- Reduced laundry service contracts and utility bills: Disposable systems eliminate the need for washing and processing. This leads to significant cost savings.

- Reduced labor hours: Less time is spent changing, counting, or restocking linens. This simplifies protocols to ‘use once and discard properly’.

- Reduced wear-and-tear on floors and equipment: Disposable microfiber systems are safe on floor finishes. They also reduce water and chemical usage.

- Reduced infection costs: Eliminating cross-contamination risks, especially in high-risk units, contributes to overall cost savings. This happens by reducing healthcare-associated infections (HAIs).

Eco-Friendly and Biodegradable Materials

The shift towards eco-friendly and biodegradable materials in healthcare offers substantial benefits. These benefits are both economic and environmental.

- Reduced Environmental Impact: Conventional cotton uses approximately 2,700 liters of water per kilogram. OEKO-TEX® certified bedding and biodegradable medical sheets can cut water and carbon footprints by over 40%.

- Long-Term Cost Efficiency: While initial investment might be higher, durability and reduced laundering needs lead to superior ROI. Some clients have reported a 30% decrease in replacement orders within the first year.

- Payback Period: Most properties see a return on investment within 18–24 months. This is due to less frequent replacements and lower utility costs.

- Meeting ESG Goals: Sustainable textiles help reduce Scope 3 emissions. They support fair labor practices and improve environmental reporting metrics.

- Reduced Water and Energy Consumption: Raenco Mills’ sustainable textiles have led to a 50% reduction in client water and energy consumption. This is through low-impact production and closed-loop dyeing.

- Enhanced Health & Safety Standards: Antimicrobial green bedding, infused with silver or copper ions, inhibits pathogens. It can reduce hospital-acquired infections (HAIs).

- Improved Comfort & Wellness: Temperature-adaptive, moisture-wicking fabrics promote better sleep and faster patient recovery.

- Marketing Edge and Customer Loyalty: Early adopters of organic hotel sheets and eco-conscious hospital linen gain a marketing advantage. They attract environmentally aware clientele. Over 70% of travelers prefer accommodation with clear sustainability credentials.

- Compliance with Standards: Government purchasing guidelines increasingly favor suppliers meeting environmental management standards like ISO 14001.

- Circularity & End-of-Life: Biodegradable or fully recyclable fabrics contribute to a circular textile economy. This reduces landfill waste. Some suppliers offer linen take-back programs for repurposing worn items.

Several environmental certifications guide the development and selection of eco-friendly materials.

- B Corp Certification: This evaluates companies on governance, workers, community, environment, and customers. It requires a minimum score of 80 on B Lab’s Impact Assessment. It focuses on energy efficiency, waste reduction, water conservation, sustainable sourcing, and carbon footprint reduction.

- USDA Organic: This certifies textile fibers grown and processed without synthetic pesticides, herbicides, or GMOs. It ensures natural fibers meet strict organic standards from cultivation to final production.

- Cradle to Cradle Certified™: This evaluates textiles across their entire lifecycle. It uses five key areas: material health, material reutilization, renewable energy, water stewardship, and social fairness.

Innovative eco-friendly materials and manufacturing processes are transforming healthcare textiles.

- The development of bio-based polymers offers advanced properties. These include enhanced strength and flexibility.

- Innovations in plant-based fibers may lead to more comfortable and durable reusable textiles.

ClothMeds, India’s first natural antimicrobial healthcare apparel maker, utilizes:

- Natural antimicrobial treatments in their medical scrubs. This reduces the need for harsh chemicals.

- Resource-efficient production methods to minimize water and energy usage.

- Durable designs for their hospital clothing to reduce replacement frequency and waste.

Chitosan is an innovative eco-friendly material. It is biodegradable, biocompatible, nontoxic, noncarcinogenic, and environmentally friendly. It offers strong antimicrobial activity against various pathogens. It can be incorporated into textiles. UV curing has been proposed as a fast and eco-friendly application process for chitosan on textiles. This mitigates disadvantages like temperature sensitivity and pH dependence. It also reduces energy consumption.

Traditional healthcare fabrics have a significant environmental impact. Hospital laundries consume 50%–75% of total hot water. This accounts for 10%–15% of a hospital’s total energy usage. This substantial consumption, with chemical usage, contributes to environmental impact. Switching to eco-friendly alternatives can reduce carbon footprints.

- Linens made from organic cotton or bamboo reduce reliance on synthetic materials and harmful pesticides. These eco-friendly fabrics are also softer and safer for patients.

- Traditional medical scrubs, often made from synthetic materials like polyester, have a significant environmental footprint. This is due to the large amounts of energy and water required for their production. They frequently end up in landfills after minimal use. This contributes to pollution and waste from healthcare facilities.

Biodegradable alternatives offer a greener path.

- Recycled Polyester: Made from post-consumer plastic bottles, it reduces plastic waste. It maintains durability and moisture-wicking properties. It is environmentally friendly and cost-effective long-term.

- Organic Cotton: Naturally breathable, soft, and free from harmful pesticides and chemicals. It is fully biodegradable and gentle on the skin.

- Bamboo Fabric: Highly breathable, moisture-wicking, and possesses antimicrobial properties. It grows quickly and requires minimal water, making it an environmentally friendly choice.

Conventional plastics, derived from petroleum, contribute to climate change. They have high carbon emissions during production. Once discarded, they persist in landfills for centuries. They break down into microplastics that contaminate water and food. This poses risks to ecosystems and human health. Recycling these plastics is energy-intensive and often impractical. This leads to landfill accumulation and potential leaching of harmful chemicals.

Biodegradable plastics offer a greener alternative. They are made from renewable resources that absorb CO₂ during growth. This lowers the carbon footprint of production. In industrial composting facilities, they break down into water, CO₂, and organic matter. This enriches the soil. They can also combine with organic waste streams. This simplifies disposal and waste management. It supports more sustainable practices. Unlike conventional plastics, biodegradable plastics are designed for biological breakdown. In environments rich in microbes, such as industrial composting facilities, bacteria and fungi decompose these plastics within a few months under optimal conditions.

Advanced healthcare fabrics are indispensable for modern patient care. Innovation, safety, and sustainability converge in these materials. Smart textiles and antimicrobial properties exemplify this progress, offering real-time monitoring and infection control. Facilities must prepare for the future by adopting these essential characteristics, ensuring optimal patient outcomes and operational efficiency.

FAQ

What makes antimicrobial properties essential in healthcare fabrics?

Antimicrobial fabrics actively reduce microbial growth. This minimizes pathogen transmission. They significantly contribute to infection control in clinical settings.

How do sustainable fabrics benefit healthcare facilities?

Sustainable fabrics reduce environmental impact and operational costs. They align with ESG goals. They also enhance patient comfort and wellness.

What makes durability crucial for healthcare textiles?

Durable fabrics withstand frequent washing and sterilization. They maintain protective qualities over time. This reduces replacement frequency and lowers long-term costs.

Post time: Jan-30-2026