Fabric blends strategically combine fibers. They optimize both economic and functional aspects. This approach creates materials that are often more cost-effective. They are better suited for specific uses than single-fiber fabrics. As a blended suit fabric manufacturer, I know blending is a strategic choice for a high cost-performance suit fabric, not a compromise. It also applies to long lasting easy care uniform fabric and polyester blended textile. For B2B suit fabric sourcing, a garment easy care suit fabric manufacturer often recommends these blends.

Key Takeaways

- Fabric blends combine different fibers. This makes materials stronger and more useful. They cost less to make than single-fiber fabrics.

- Blends fix problems of single fibers. For example, cotton and polyester together are strong and resist wrinkles. This makes clothes last longer and easier to care for.

- Choosing the right blend depends on what you need. Different blends work best for suits, uniforms, or activewear. This helps balance cost and how well the fabric works.

Why Fabric Blends Offer Superior Cost-Performance

Combining Strengths for Enhanced Performance

I find that fabric blends truly excel by combining the best attributes of different fibers. This approach creates materials with enhanced properties that single fibers often cannot achieve alone. For instance, when I blend natural and synthetic fibers, I can engineer fabrics with increased durability, superior wrinkle resistance, better stretch, and improved comfort. Consider a cotton and polyester blend; it results in a fabric that is breathable, easy to care for, and resistant to shrinking.

I have seen how blending significantly improves durability. Synthetic fibers, for example, enhance tensile strength and abrasion resistance when I combine them with natural fibers. Even cotton-silk blends show improved abrasion resistance for the silk component. I also focus on enhanced breathability and comfort. Polycotton, for example, combines polyester’s durability with cotton’s moisture-absorbing and air-permeable qualities, making it a popular choice.

Blends also offer increased versatility. I can engineer them for specific functional properties like water or wind resistance by incorporating performance-modified fibers. This expands their applications significantly. Ease of maintenance is another key benefit; blended fabrics generally have good dimensional stability, reducing shrinkage and wrinkling. The inclusion of synthetics often allows for machine washing, simplifying care for the end-user. Finally, I can control aesthetic and textural properties like luster, texture, drape, and dye affinity through blending. A cotton-silk blend can retain silk’s sheen while incorporating cotton’s matte appearance, and wool-polyester blends can reduce weight and impart a crisper handle.

I often use specific blend ratios to achieve these superior performance characteristics. For example, I know that:

| Blend Ratio | Ideal Application | Highlighted Benefit |

|---|---|---|

| 80% Acrylic / 20% Cotton | T-shirts, polos, loungewear | Vibrancy and softness |

| 50/50 Blend (Acrylic/Cotton) | Light sweaters, cardigans | Breathability with structure |

| 30% Acrylic / 70% Cotton | Summerwear, undershirts | Natural touch with easy-care handling |

| 70% Acrylic / 30% Cotton | N/A | Excellent Colorfastness, Excellent Wrinkle Resistance, Soft Hand Feel |

| 50% Acrylic / 50% Cotton | N/A | High Breathability, Good Colorfastness, Good Wrinkle Resistance, Balanced Hand Feel |

| 30% Acrylic / 70% Cotton | N/A | Very High Breathability, Moderate Colorfastness, Fair Wrinkle Resistance, Natural Hand Feel |

Blending acrylic with other fibers enhances specific textile attributes. I can optimize fabric performance, reduce production costs, and create materials tailored for specific applications like fashionwear or technical textiles. Acrylic improves the softness, bulk, and insulation of synthetic blends. It also adds shape retention and colorfastness to natural fibers like cotton and wool. Additionally, acrylic fibers improve machine washability and reduce shrinkage and wrinkling common in pure natural fibers.

Reducing Production Costs with Blending

From my perspective, fabric blends offer significant economic advantages in textile manufacturing. They enable more efficient production processes. I find that they require less water and energy compared to traditional methods, which directly lowers the carbon footprint of textile manufacturing. This increased efficiency translates into economic savings for manufacturers due to reduced resource consumption.

I also see how using fabric blends, incorporating materials like organic cotton, recycled polyester, and hemp, allows me to minimize waste and resource consumption. This reduction in material usage and environmental impact contributes to economic benefits by optimizing production costs and aligning with sustainable practices. Ultimately, fabric blends reduce overall production costs for textile manufacturers by allowing me to combine expensive fibers with cheaper alternatives. This strategy helps me maintain quality while achieving cost efficiency.

Overcoming Individual Fiber Weaknesses

I have learned that blending fibers is an excellent strategy for overcoming the inherent weaknesses of individual fibers. For example, cotton naturally absorbs sweat and allows air circulation. However, acrylic in a blend reduces cotton’s tendency to feel soggy or heavy by speeding up drying time and improving airflow. This creates a more comfortable garment.

I also address color and fade resistance. Acrylic in the blend helps preserve bright, solid colors over dozens of home laundry cycles. This offsets cotton’s tendency to fade more quickly with sunlight and washing. Furthermore, I use acrylic to offset cotton’s tendency to wrinkle and shrink after washing. This improves shape memory and wrinkle resistance, making blended garments much easier to care for.

Blending acrylic with wool offers the best of both worlds: the luxurious feel and natural insulation of wool, and the light weight, low cost, and shape stability of acrylic. This blend is especially popular in winterwear, soft accessories, and mid-market fashion items. Acrylic also reduces the itchiness often associated with lower-grade wool, making the blend smoother and easier to wear next to skin. Furthermore, acrylic-wool blends can be machine-washed on gentle cycles without major shrinkage or felting, unlike 100% wool garments which often require dry cleaning.

I have seen firsthand the results of such strategic blending. For example, a uniform manufacturer created a 65/35 acrylic-nylon blend for industrial jumpers. The garments passed both abrasion resistance and tensile strength tests (ASTM D5034) with flying colors, while retaining 90% color intensity after 20 industrial wash cycles. This demonstrates how blending effectively mitigates weaknesses and enhances performance.

Common Blends: Balancing Cost, Appearance, and Stability

Cotton-Polyester Blends for Durability and Comfort

I often rely on cotton-polyester blends for their excellent balance of durability and comfort. These blends combine the best features of both fibers. For example, I use specific ratios for workwear:

| Blend Ratio | Best Uses |

|---|---|

| 65% Polyester, 35% Cotton | Workwear, uniforms, activewear, industrial wear, aprons, medical scrubs |

This blend offers superior performance compared to 100% cotton. I find it provides:

- Versatility: It suits many uses.

- Color Retention: It holds color better, resisting fading.

- Durability: It resists pilling and wear.

- Wrinkle Resistance: It wrinkles less, reducing ironing.

- Ease of Care: It washes and dries easily.

- Shrinkage Resistance: It maintains size and shape.

Wool-Synthetic Blends for Warmth and Practicality

For warmth and practicality, I turn to wool-synthetic blends. I blend wool with synthetics like nylon, acrylic, and polyester. Nylon, for instance, dramatically increases yarn strength and abrasion resistance, extending the life of items like socks. Acrylic adds lightness and washability. Polyester contributes strength and color-fastness. These blends are less prone to wrinkling or shrinking, which means easier maintenance and less frequent dry cleaning. Wool’s natural fibers offer insulation, and synthetics enhance moisture-wicking.

Silk-Cotton/Rayon Blends for Accessible Luxury

I create accessible luxury with silk-cotton and silk-rayon blends. These blends offer a luxurious feel without the high cost of pure silk. For silk-cotton blends, I often use a 60% silk and 40% cotton ratio. For silk-rayon blends, popular ratios include 70/30 or 80/20 (Rayon/Silk). This allows me to achieve a beautiful drape and soft hand feel at a more affordable price point.

Spandex Blends for Enhanced Stretch and Fit

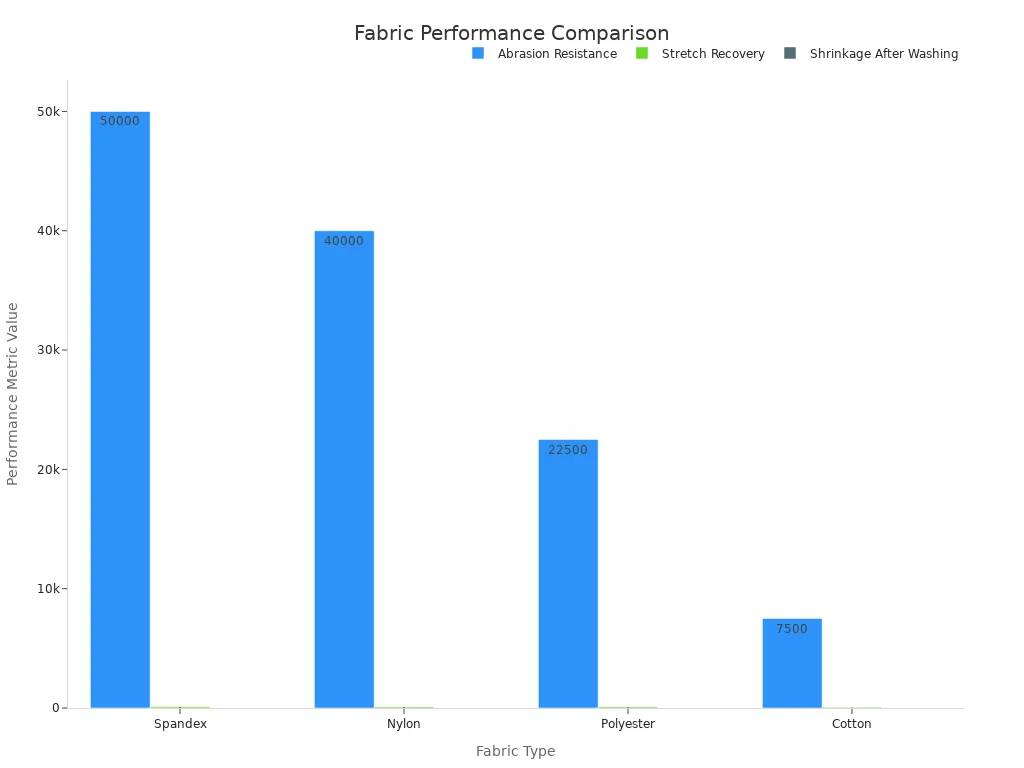

I incorporate spandex into fabrics for enhanced stretch and fit, especially in activewear. For general activewear, I typically use 8–12% spandex. Running tights and gym leggings often have 10–15% spandex for a snug fit. For compression gear, I go higher, using 15–20% or more. Spandex offers significant performance benefits:

| Feature | Spandex Contribution to Durability | Performance Apparel Benefit |

|---|---|---|

| Resistance to Abrasion | Spandex is resistant to abrasion, ensuring garments don’t wear out quickly | Increases lifespan, making activewear more cost-effective for consumers |

| Elastic Recovery | Retains its shape even after multiple stretches | Activewear maintains its fit and performance after extensive use |

| UV Resistance | Spandex can withstand UV exposure without degrading | Provides long-lasting protection for athletes working outdoors |

| Shrinkage Resistance | Spandex doesn’t shrink when washed | Ensures garments maintain their fit and size even after repeated washing |

Spandex excels in abrasion resistance, stretch recovery, and UV protection. This makes it ideal for activewear that faces frequent washing, physical activity, and outdoor conditions.

Factors Beyond Fiber Type in Cost-Performance

Blend Ratio’s Impact on Final Product

I understand that the specific blend ratio significantly influences a fabric’s final cost and performance. For example, I have seen how specific wool-modal blend ratios, like 50:50 and 70:30, optimize tensile strength, elongation, and air permeability. These blends often outperform fabrics made from 100% wool or modal alone. A higher wool content, such as in a 70:30 wool-modal blend with 20 Ne yarn, increases fabric weight, density, and warmth. Conversely, finer yarns, like a 100% wool fabric with 40 Ne yarn, enhance drapability. I find the 50:50 wool-modal blend with 30 Ne yarn achieves a good balance of thread density, softness, and breathability. The 70:30 wool-modal blend provides greater thermal insulation but has a coarser texture. Yarn count also affects properties; a 30 Ne yarn count is ideal for both 50:50 and 70:30 wool-modal blends for enhanced performance.

Yarn Construction and Fabric Weave Influence

Yarn construction and fabric weave also play crucial roles in cost and performance. Softer, more pliable fibers, like silk or cotton, contribute to better drape than linen. Highly twisted yarns are stiffer, while loosely spun yarns are more pliable. Smooth, worsted-spun yarns are drapier because fibers slip past each other easily. Fuzzy, woolen-spun yarns are more elastic. Heavier fibers, such as alpaca, can also contribute to drape.

I also consider the weave structure. Weave structures with floats, like twills, generally have more drape than plain weaves. Here is how different weaves compare:

| Property | Satin Weave | Plain Weave | Twill Weave |

|---|---|---|---|

| Tensile Strength | Medium–High | High | Very High |

| Tear Strength | Medium | Medium–High | High |

| Snag Resistance | Low–Medium | High | Medium |

| Abrasion Resistance | Medium–High (if polyester/nylon) | Medium | High |

| Drape | Very High | Medium | Medium–High |

Finishing Treatments for Added Value

I apply various finishing treatments to fabric blends to add value and specific functionalities. These treatments enhance both aesthetics and performance. For instance, I use thermal fabric finishes to set or modify fabric structures, preventing shrinkage. Aesthetic finishes, like dyeing and printing, add color and patterns. Performance finishes improve functional properties. These include antimicrobial treatments, UV protection, and stain resistance.

I also use durable press finishes to reduce wrinkling. Water repellent finishes resist water penetration. Flame retardant finishes reduce flammability. Softening finishes improve the fabric’s hand feel. Specialty finishes like VanGuard ensure fabrics remain smooth and crisp through multiple washes. HydraGuard, a water and stain repellent technology, creates an invisible barrier. It repels liquids and resists stains. These finishes significantly enhance the performance of fabrics. They add practical benefits without compromising the fabric’s natural feel or appearance.

Choosing the Right Blend: A Practical Guide

Defining Priorities for Specific Applications

I always begin by defining the specific priorities for each application. This step is crucial for selecting the optimal fabric blend. For outdoor apparel, for example, I know certain properties are non-negotiable. I prioritize moisture-wicking to pull sweat away from the body. This keeps the wearer dry and comfortable during strenuous activities. Breathability is also key. It allows air to circulate freely. This regulates body temperature and prevents overheating.

Durability is another essential factor. I engineer outdoor fabrics to withstand harsh conditions. This includes abrasion resistance and colorfastness. These features ensure the apparel endures diverse environments. Flexibility enhances functionality for various activities. It allows for ease of movement. Stain resistance provides an extra layer of protection. It contributes to durability and longevity. Finally, I focus on sustainability. I integrate eco-friendly elements and sustainable practices. This aligns with environmentally conscious consumer preferences. I often use polyester and Merino wool for moisture-wicking. Nylon provides toughness. Gore-Tex membranes offer breathability and waterproofing.

For medical wear, the priorities shift. I focus on sterility, durability, and comfort. Polyester and spandex blends are excellent choices. They often incorporate moisture-wicking technology for dryness. They also provide stretch for free movement. Surgeons benefit from their stretch and stain resistance. ER staff need durability and fluid resistance. Polyester-based fabrics excel with stain- and fluid-repellent coatings. They maintain a clean appearance. Cotton-polyester blends are good for nurses. They offer comfort and easy maintenance.

I recall a rehabilitation center’s trial. An 80/20 cotton/polyester blend offered an appealing compromise. It provided 90% of cotton’s airflow. It also had 20% greater tensile retention. Its lifespan extended to 50 cycles compared to 100% cotton’s 30 cycles. Patients rated this blend highest for ‘coolness.’ Laminated cotton-polyester hybrids were effective in a trauma center. They eliminated mid-procedure gown replacements due to fluid saturation. This saved an average of 15 nursing hours monthly. This demonstrates optimal fluid management. I also use 95% polyester / 5% spandex blends. They are lightweight, stretchy, and moisture-wicking. They resist pilling, shrinking, and fading. They maintain shape after washes. They also offer antimicrobial benefits. Treated polyester or poly-cotton fabrics provide fluid resistance and antimicrobial protection. These are vital in high-risk departments.

Understanding Intended Use for Optimal Blends

The intended use of a garment significantly influences my blend selection. It dictates the necessary features and prioritizes functionalities. For specialized protective gear, I first define the purpose. Is it for outdoor adventures, self-defense, or law enforcement? This helps me identify specific requirements. These might include flame resistance or ballistic protection. The user’s role also matters. A police officer or military personnel has different needs. Their responsibilities determine the required protection levels. They also determine if comfort and durability are high priorities for daily or extended use.

Environmental factors are crucial. Climate, weather, and terrain play a significant role. Harsh winters necessitate insulated clothing. Hot climates require breathable, moisture-wicking fabrics. These considerations collectively guide my selection of materials and features. They ensure appropriate protection, functionality, and comfort.

I consider the specific application. For wetsuits and cold water use, I prioritize insulation and stretch. These typically require a thickness range of 3-6mm. Medical supports need compression and stability, often 2-4mm thick. Fitness and training apparel demand flexibility and comfort, usually 1-3mm. Lifestyle and fashion items focus on aesthetics and basic comfort, around 0.5-1.5mm. For warm or active use, I choose thinner neoprene. I also use perforated designs and hybrid panels.

For specialized protective clothing, like medical gowns, I prefer synthetic fibers. Polypropylene and polyester are better than natural fibers like cotton or wool. Their structure and interaction with fluids prevent liquid absorption. They also prevent bacterial trapping. Reusable gowns often use tightly woven fabrics. They have chemical finishes to improve liquid barrier properties. These are typically 100% cotton, 100% polyester, or polyester/cotton blends. Historically, cotton muslin fabrics were popular for comfort. However, they failed due to poor liquid penetration resistance. Polyester/cotton blends offered comfort but failed microbial penetration resistance. Woven polyester (T280) provides better water-repellency and protection. However, it can compromise thermal comfort. Modern reusable surgical gowns use woven polyethylene terephthalate (PET) in non-critical zones. They use knitted PET with barrier fabrics in critical zones. This balances protection and comfort.

High Cost-Performance Suit Fabric Considerations

When I design a high cost-performance suit fabric, I focus on a delicate balance. I need durability, drape, and wrinkle resistance. A high cost-performance suit fabric must look good and last long. Wool blends, especially with synthetic or regenerated fibers, offer improved durability. They maintain good drape and have improved wrinkle resistance. Wool-silk blends provide good structure and composure. They offer a refined, smoother drape. They also maintain good wrinkle resistance. Linen blends, with wool or other fibers, show improved structural stability. They have a smoother drape and improved wrinkle recovery. Polyester blends are long-lasting and wrinkle-free. However, they are less breathable and less refined. I always weigh these factors for a high cost-performance suit fabric.

Breathability and comfort are paramount for a high cost-performance suit fabric. This is especially true in various climates. Mohair blends, from Angora goat wool, are durable, lustrous, and crease-resistant. This makes them suitable for travel and transitional seasons. They offer breathability and understated luxury. Silk blends, combined with wool or linen, provide luxury, breathability, and a lightweight, soft feel. They are ideal for special occasions. Linen suits provide high breathability. They are perfect for hot weather, though they wrinkle easily. Wool blends and synthetic fabrics offer better wrinkle resistance. This ensures a polished look. Synthetic materials like polyester, nylon, and rayon, often blended with natural fibers, provide durability, wrinkle resistance, and affordability. However, they generally lack the breathability of natural fibers. This can lead to discomfort in hot conditions. A silk-wool blend combines silk’s luxury with wool’s durability. Fabric weight is also crucial. Lighter fabrics suit warmer climates. Heavier ones are for cooler months. Wool, for example, adapts well in both lightweight and heavyweight options. I always aim for a high cost-performance suit fabric that meets these diverse needs.

I find fabric blends offer a sophisticated solution. They achieve an optimal balance between cost and performance. They provide versatility and functionality single fibers often cannot. This meets diverse needs. Informed choices in blending lead to materials that excel. They show excellence in cost control, appearance, performance stability, and large-scale production.

FAQ

What is the main advantage of using fabric blends?

I find fabric blends offer superior cost-performance. They combine fiber strengths. This creates materials that are both affordable and highly functional for specific uses.

Why do I often use cotton-polyester blends?

I use cotton-polyester blends for their durability and comfort. They resist wrinkles and shrinkage. They also hold color well, making them easy to care for.

How does spandex improve fabric performance?

I incorporate spandex for enhanced stretch and fit. It provides excellent elastic recovery. This ensures garments maintain their shape and offer freedom of movement.

Post time: Jan-12-2026