Introduction

Color consistency is one of the most critical factors for medical garment brands—especially when it comes to white fabrics. Even a slight variation between the collar, sleeves, or body of a uniform can affect the overall appearance and brand image.

At Yunai Textile, we recently worked with a large international medical wear brand that had previously faced this very issue with another supplier. Their finished garments showed visible color discrepancies, and they were determined not to face that challenge again.

Understanding the Client’s Challenge

The client shared their concern:

“Our previous supplier’s white fabrics had noticeable color differences—collars looked slightly off-white compared to the body, and sleeves didn’t match perfectly.”

We understood how crucial uniform color was for medical apparel—where cleanliness, precision, and professional presentation matter most.

That’s why, from the very beginning of production, we focused on color accuracy and consistency at every stage.

Our Color Control Process

1. Bulk Dyeing and Formula Control

All bulk dyeing batches are processed at the same time, using the same dye formulation to ensure color uniformity.

After dyeing, we conduct immediate inspections.

If any shade variation is detected, our technicians adjust the dye formula promptly to maintain the required brightness and whiteness level.

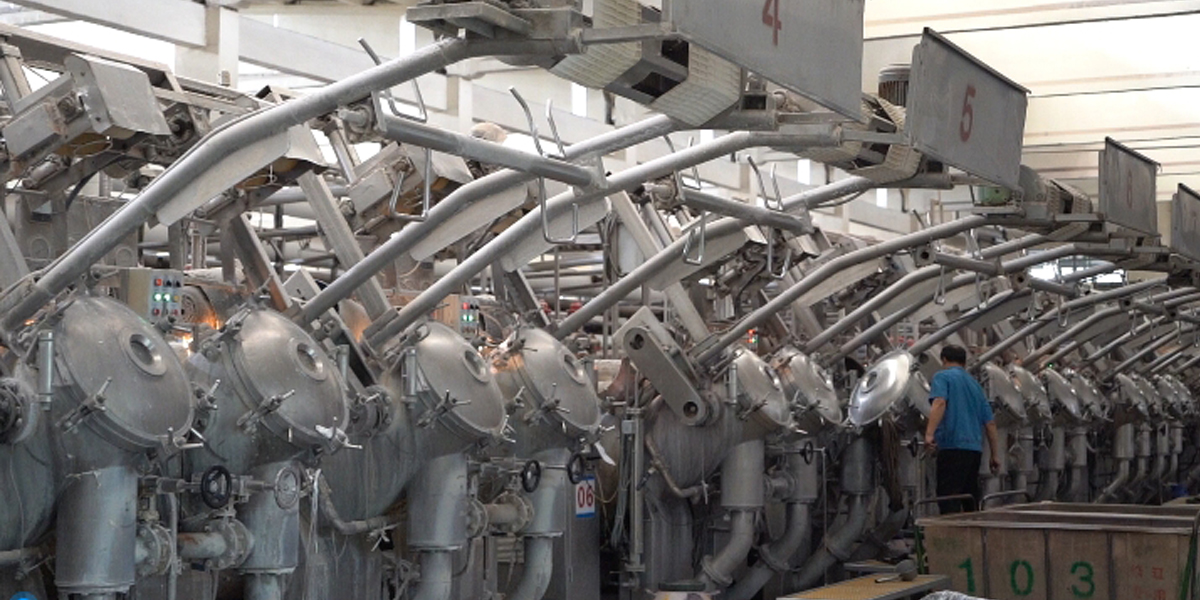

2. Finishing and Machine Cleanliness

Before finishing, our team performs a complete cleaning of the stenter machine to avoid contamination from previous fabrics.

During the finishing process:

-

Machine speed is kept constant to ensure even heat exposure.

-

Left and right heating chambers are calibrated to maintain equal temperature distribution.

-

The entire process is monitored for cleanliness and precision.

These steps guarantee that no yellowing or subtle tone variation occurs during heat setting.

3. Final Inspection and Color Matching

Once the fabric is finished, we carry out side-by-side color comparison under both natural and standard artificial lighting.

Every roll is carefully inspected before packing, ensuring that all parts—collar, sleeves, and body fabric—come from the same lot and have consistent whiteness.

The Result

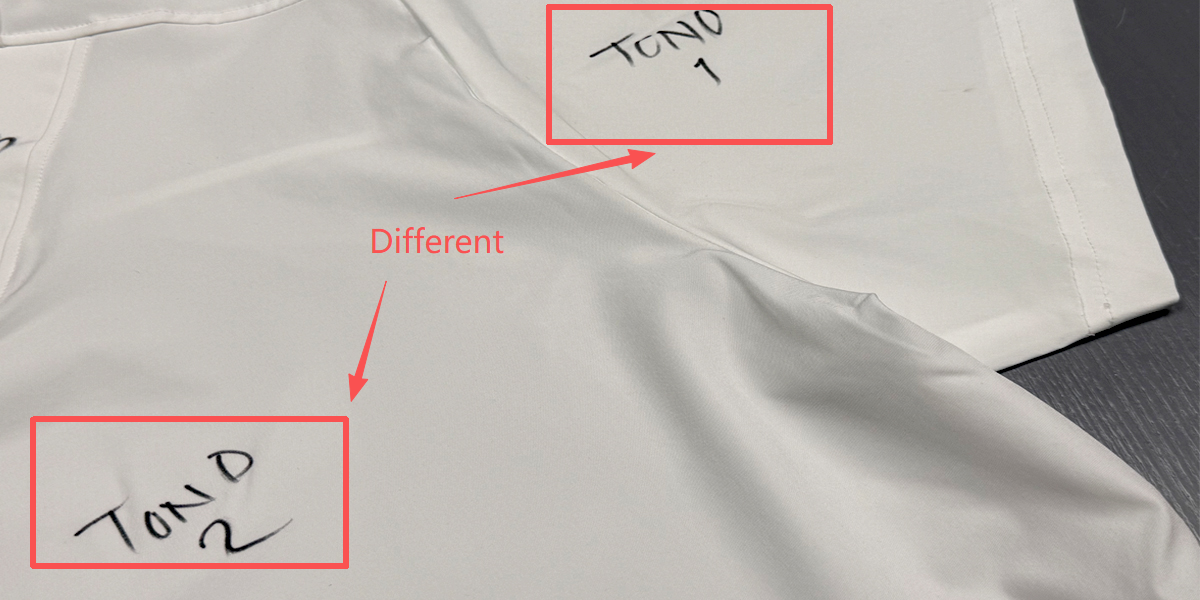

When our client received the final bulk fabrics, they conducted their own garment production tests.

The result: no color difference, perfect visual consistency, and full satisfaction.

Because of our meticulous production control and quality assurance, the client placed an additional order of over 100,000 meters shortly after.

Our Commitment to Quality

At Yunai Textile, we believe true quality comes from attention to detail.

From fabric dyeing to finishing, and from inspection to garment production guidance, our process ensures that every meter of fabric meets the high standards expected by leading medical garment brands.

If your brand values color accuracy, reliability, and long-term partnership, we’re ready to support your next collection.

Post time: Oct-14-2025