I find tear resistance paramount. Materials endure constant movement, stress points, or face nicks. This is critical for materials under tension or in abrasive conditions. Small defects can quickly become larger failures. A professional outdoor woven kintfabric manufacturer prioritizes fabric tear resistance. They ensure outdoor sports fabric quality control. This includes 100 polyester blended outdoor fabric strength. A professional uniform fabric manufacturer needs tear resistant fabric.

Key Takeaways

- Tear resistance stops small damage from becoming big problems. It makes products last longer and keeps people safe.

- We measure tear resistance with special tests. These tests show how much force a material can handle before it tears.

- Tear resistance is important for many things. It helps choose the best materials for clothes, tents, and car parts.

Why Tear Resistance Matters for Material Durability

Preventing Catastrophic Failure

I understand that tear resistance is a critical property. It directly prevents small damage from becoming a major failure. A tiny nick or a small cut can quickly expand under stress. This expansion leads to a complete material breakdown. High tear resistance means the material can resist this propagation. It contains the damage to a localized area. This capability is vital for maintaining structural integrity. It stops a minor flaw from causing a catastrophic event.

Extending Product Lifespan

I believe that materials with superior tear resistance simply last longer. Products face daily wear and tear. They encounter snags, abrasions, and impacts. A material that resists tearing will endure these challenges better. This durability translates into an extended product lifespan. Consumers benefit from products that do not need frequent replacement. Manufacturers gain a reputation for quality and reliability. It is a win-win situation for everyone involved.

Ensuring Performance and Safety

I prioritize tear resistance because it directly impacts performance and safety. In many applications, material failure can have serious consequences. Imagine a safety harness or a protective garment. A tear in these items compromises their function. It puts the user at risk. High tear resistance ensures the material performs as intended. It maintains its protective qualities even under stress. This reliability is non-negotiable for safety-critical products. I always consider this aspect during material selection.

Real-World Scenarios and Material Stress

I see the importance of tear resistance clearly in many real-world applications. Materials constantly face stress that can lead to tearing. This stress comes from various sources.

- Regular clothing: Daily movements and accidental snags test the fabric.

- Athletic clothing: Intense physical activity puts strain on seams and fabric panels.

- Camping equipment: Tents and backpacks encounter sharp rocks and branches.

- Furniture: Upholstery endures constant friction and potential punctures.

- Manufacturing environments: Conveyor belts and protective covers face abrasive conditions.

- Upholstery and automotive fabrics: These materials must withstand repeated use and potential damage.

- Automotive and home textile manufacturing: Here, the fabric tear resistance is a key quality metric.

These examples show why I consider tear resistance a primary factor. It ensures product performance under diverse and demanding conditions.

How Tear Resistance is Measured and Interpreted

I find understanding how we measure tear resistance crucial. It helps me make informed decisions about material selection. We use specific tests to quantify a material’s ability to resist tearing. These tests provide valuable data, but interpreting them correctly is key.

Standardized Testing Methods

I rely on standardized testing methods to ensure consistency and comparability. These methods provide a common language for engineers and manufacturers worldwide. They help me evaluate different materials objectively. The most widely accepted methods come from organizations like ISO and ASTM. I often refer to these standards.

For instance, I use:

- ISO 34-1:2015 for rubber, which determines tear strength using various test pieces.

- ISO 9073-4:2019 for nonwoven textiles, specifically measuring tear resistance.

- ISO 6383-2:1983 for plastic film, using the Elmendorf method.

- ASTM D1004-13 for plastic film, determining tear resistance (Graves Tear).

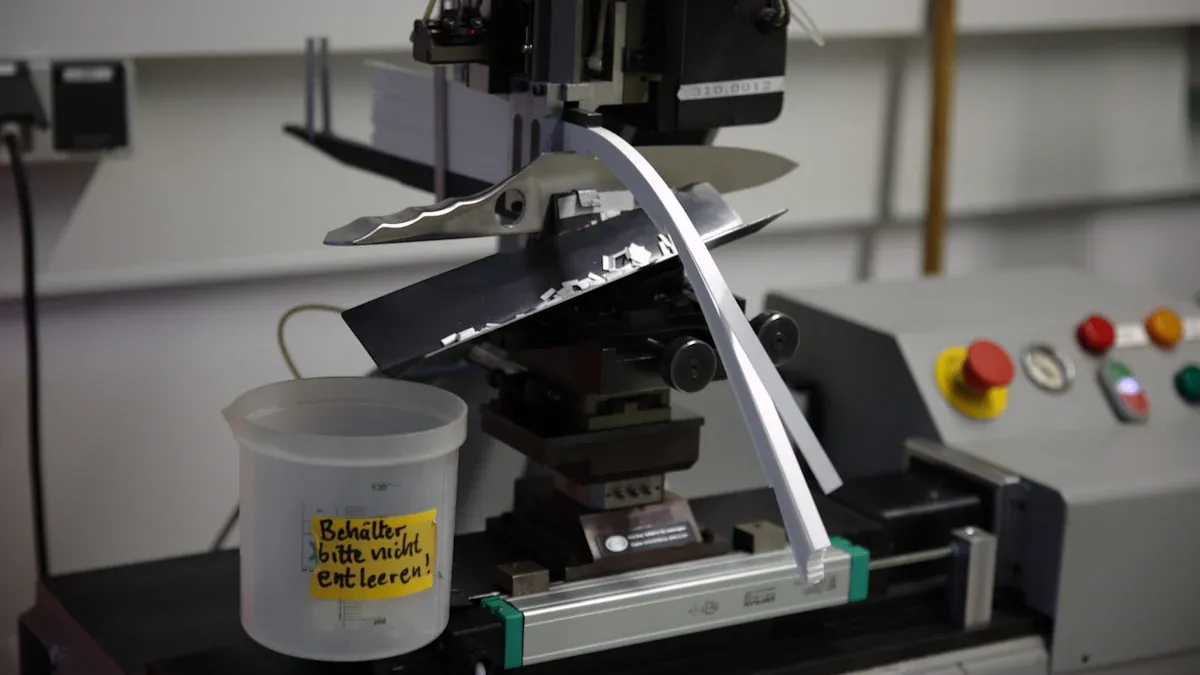

- ASTM D1424-09(2013)e1 for fabrics, using a falling-pendulum (Elmendorf-Type) apparatus.

- ASTM D1938-19 for plastic film, measuring tear-propagation resistance (Trouser Tear).

These standards ensure I compare apples to apples when evaluating material properties.

Differentiating Tear Initiation and Growth

I recognize that tear resistance involves two distinct phases: initiation and propagation. It is important to understand the difference.

- Tear Initiation: This refers to the resistance a material offers to the initial formation of a tear. I look at how much force it takes to start a rip.

- Tear Propagation (Growth): This refers to the resistance a material offers to the expansion or continuation of an existing tear. Once a tear starts, I want to know how much force it takes to make it bigger.

Tear strength quantifies the force needed to both initiate and continue a tear within the fabric. This often depends on the direction of the force. I consider both aspects when I assess a material’s overall tear resistance.

Challenges in Real-World Correlation

I find correlating laboratory tear resistance results with real-world performance quite challenging. Tear resistance is a complex property. It results from other basic material characteristics like modulus and tensile strength. While lab tests are useful for comparisons, a direct correlation to actual service performance is often difficult.

I know several factors complicate this:

- Laboratory testing is easily affected by equipment operation.

- Human intervention during testing can significantly influence results.

- The test environment itself impacts tear resistance measurements.

Real-world conditions are dynamic and unpredictable. They involve fluctuating weather, pollution, and physical wear. These factors are hard to replicate precisely in a controlled lab. Materials in real-world applications also interact with unexpected elements like chemicals or biological agents. These interactions may not be accounted for in accelerated tests. Accelerated tests, designed to shorten evaluation time, may not capture long-term fatigue effects. Gradual degradation processes only become apparent under natural conditions over extended periods. Products in the field experience varied handling, maintenance, and unintended usage patterns. I cannot accurately mimic these in laboratory tests. This leads to discrepancies between predicted and actual performance.

Understanding Fabric Tear Resistance

I pay close attention to fabric tear resistance. It is a critical property for textiles. Specific ASTM or ISO standards help me evaluate it.

For example, I use:

- ASTM D2261 (Tongue Tear method): This measures the average force needed to continue a tear. It involves pulling apart two ‘tongues’ cut into the specimen. This method applies to most textile fabrics, including woven, knitted, or unwoven materials. I make a cut in a rectangular specimen to start a tear. Then I pull the two sides until failure. The data reflects the strength of yarns, fiber bonds, and fiber interlocks. It also shows their resistance to tearing.

- ASTM D1424 (Elmendorf method): This utilizes a falling pendulum apparatus. It measures the work done (energy) to propagate a predefined slit across the fabric.

- ASTM D5735: This covers the measurement of tearing strength of nonwoven fabrics by the tongue procedure.

- BS EN 1875-3:1998: This determines the tear strength of rubber and plastics-coated fabrics using the trapezoidal method.

These methods give me specific data points. They help me understand how a fabric will perform under tearing stress. I use this information to select the best materials for various applications.

Typical Values and Material Considerations

Tear Strength Across Material Types

I have observed a wide range of tear strengths across different material types. Polyurethane can achieve very high tear strengths. It reaches as high as 1,000 pounds per linear inch (175.1 kN/m) using ASTM D-624, Type C. Elastomeric materials generally show a tear strength in the range of 50–100 kN/m. I also see variations within rubber types:

| Material Type | Specific Material | Tear Strength (kN/m) |

|---|---|---|

| Rubber | Natural Rubber | 23.95 +/-1.85 |

| Rubber | Nitrile Rubber | 9.14 +/-1.54 |

Plastic films also vary. High-density polyethylene (HDPE) in the machine direction (MD) has a tear strength of 120g. Low-density polyethylene (LDPE) shows 320g (MD).

Factors Influencing Tear Strength

I understand that many factors influence a material’s tear strength. Higher molecular weight polymers show better tear resistance. This is due to stronger bonds and longer chains. Polymer chain orientation can increase tear resistance in one direction. However, it might decrease it in others. Additives like fillers can increase stiffness but reduce tear resistance. They create stress points. Plasticizers improve flexibility but can reduce tear resistance. Crystal orientation also affects tear strength. Films with preferred crystal orientation can have lower tear strength. The type of co-monomer matters too. For example, LLDPE with octene and hexene co-monomers has better intrinsic tear strength. Tear strength is the maximum force needed to tear a specimen. I express it as force per unit of specimen thickness.

Material Selection for Specific Applications

I carefully select materials for specific applications based on their tear resistance. For high elasticity and tear resistance, I often choose Elastomeric Polyurethanes (EPU). These are good for gaskets and seals. Polyurethane Rubber offers extreme resistance to abrasion and tearing. This makes it ideal for heavy-duty industrial uses. Natural Rubber (NR) has high tensile strength and tear resistance. I use it in shock-absorbing mounts. For extreme temperatures, I consider Polyimide materials like Kapton®. They maintain flexibility and resist decomposition at high heat. Mica-based solutions provide unmatched temperature resistance. Composite constructions offer optimal solutions. They combine materials like polyimide films with mica papers. This addresses thermal stability, mechanical durability, and fabric tear resistance.

I find tear resistance a critical property for material selection. It matters in applications with dynamic stress, sharp objects, or abrasive conditions. Prioritizing tear resistance ensures long-term durability, reliability, and safety. Understanding when and why tear resistance matters empowers my better engineering and product development decisions.

FAQ

What is the primary purpose of tear resistance?

I use tear resistance to prevent small damage from becoming catastrophic failures. It helps extend product lifespan and ensures safety.

How do I measure tear resistance?

I measure tear resistance using standardized methods like ASTM and ISO tests. These tests quantify the force needed to initiate and propagate a tear.

Why is real-world correlation challenging for tear resistance?

I find real-world correlation challenging because lab tests cannot fully replicate dynamic, unpredictable conditions like weather, pollution, and varied usage patterns.

Post time: Dec-31-2025