I understand fabric durability is about balance, not just maximum uniform fabric strength. For effective performance, especially in medical fabric durability, balanced properties are crucial. A functional woven fabric demands more than raw power. This balanced approach guides my performance fabric selection as a reliable uniform sportswear fabric textile partner.

Key Takeaways

- Fabric durability needs many good qualities, not just being super strong. A fabric that works well has a mix of things like tear strength and flexibility.

- Too much strength can make fabric stiff, uncomfortable, and expensive. It is important to find a good balance for how the fabric will be used.

- Different uses for fabric need different types of strength. For example, clothes for everyday wear need comfort, but outdoor gear needs to be waterproof and tear-resistant.

Why Maximum Strength Alone Isn’t Optimal for Fabric Durability

Strength Does Not Guarantee Fabric Longevity

I often see people equate maximum strength with ultimate durability. This is a common misconception. While strength is a crucial indicator for evaluating the durability of fabrics, it encompasses various aspects. These include tear strength, breaking strength, rupture strength, and peel strength. I know from experience that a material can possess incredible breaking strength but still fail quickly in real-world conditions. For instance, tear strength refers to the force required to initiate a tear in a fabric. Tear resistance is the material’s ability to prevent or stop an existing tear from enlarging. High tearing strength levels enhance overall material quality. A material with high tear resistance will not extend quickly even if it is torn, making it stronger and more durable. Consider materials like Kevlar, an aramid fiber known for amazing strength and great tear resistance. It finds use in products demanding extreme durability like body armor. Dyneema, a type of polyethylene, also offers exceptional strength and lightweight properties. Manufacturers utilize it in applications requiring high tearing strength such as climbing gear and military equipment. These examples show that specific types of strength, like tear resistance, contribute more directly to longevity than just raw tensile strength.

Over-Engineering Can Detract from Fabric Utility

I have observed that pushing for maximum strength can sometimes lead to over-engineering. This actually detracts from a product’s overall utility. Excessive stiffness in materials significantly impacts garment wearability. This is particularly true concerning the ease of donning and doffing. For inextensible materials, design features like positive ease or closures, such as zippers or snaps, are essential. They allow the garment to be put on and taken off. Without these, garments would be difficult or impossible to wear. I think about dress trousers. Non-compliant dress trousers require added dimension (positive ease) to enable donning and doffing. If designers intend them to fit tightly around the ankle, a side closure is necessary. This allows the foot to pass through and then refasten for fit. In contrast, stretch leggings, while they can strain as the foot passes through, generally allow for donning without additional closures. This is due to their compliant nature. Even in advanced functional apparel, some stiffness is necessary for actuators and sensors. However, excessive stiffness complicates the don/doff process. It creates a trade-off between adjustability and functionality. This necessitates complex size-adjustability mechanisms to achieve a close fit when stiffness is required. Ultimately, this hinders consumer usability.

The Impact of Excessive Strength on Fabric Cost and Comfort

I also consider the practical implications of excessive strength on both cost and comfort. Manufacturers often achieve maximum strength through denser weaves or specialized materials. This directly impacts the final price. More importantly, it can severely compromise comfort. High-density materials, for example, lead to low breathability. This is due to fewer gaps between yarns. Conversely, low-density materials have larger gaps, resulting in better breathability. While low breathability can be advantageous for specific applications like windproof jackets, preventing air passage, it is generally undesirable for everyday wear. I know that lighter weight materials typically offer better breathability. However, they may compromise durability and coverage. Loose weaves, such as voile and gauze, enhance breathability due to high air permeability. They may compromise durability. Tight weaves, like canvas and twill, improve durability by offering strong resistance to abrasion. However, they can restrict airflow. Higher thread counts generally reduce air permeability, impacting breathability. They can improve moisture-wicking through increased capillary action. The optimal material density depends on its intended application. Balancing construction parameters is crucial. This maintains adequate strength and appearance while optimizing breathability. I always aim for this balance to ensure both performance and user satisfaction.

Essential Factors for Balanced Fabric Durability

I understand that true fabric durability comes from a balance of many properties. Maximum strength alone does not create a truly resilient material. Instead, I focus on several key factors that work together. These factors ensure a material performs well and lasts long in its intended application.

Abrasion Resistance for Surface Wear of Fabric

Abrasion resistance is crucial for any material that experiences rubbing or friction. It measures how well a material withstands surface wear. I know that without good abrasion resistance, a material can quickly look worn and degrade. To assess this, I rely on standardized test methods. For example, ASTM D4966 uses the Martindale Abrasion Tester Method. This method determines the abrasion resistance of various textile fabrics, including knit, woven, and nonwoven types. It simulates the frictional forces a material experiences during use. Other important methods include ASTM D3884, D3885, D3886, D4157, D4158, and AATCC TM93. For footwear materials, ISO 20344 specifies general requirements and test methods for abrasion resistance. JIS L1096 also outlines testing methods for woven and knitted materials, contributing to overall quality.

I also consider typical abrasion resistance ratings when selecting materials. Here is a general guide:

| Fabric Type | Martindale Cycles | Wyzenbeek Double Rubs | Taber Cycles |

|---|---|---|---|

| Cotton Broadcloth | 2,500 | N/A | 1,000 |

| Polyester | 3,500 | 8,000 | 1,500 |

| Nylon | 4,500 | 8,000 | 1,500-2,000 |

| Linen Canvas | 5,500 | N/A | 1,500-2,000 |

| Wool | 1,000 (pilling) | 3,000 | 500 (pilling) |

| Heavyweight Denim | >8,000 | >12,000 | >3,000 |

Tear Strength for Fabric Structural Integrity

Tear strength is another vital component of durability. It measures a material’s ability to resist the propagation of a tear once it has started. I find several factors influence a material’s tear strength:

- Fiber Type: Man-made fibers like polyester and nylon generally have greater tearing strength than natural fibers such as cotton or wool. The inherent strength of the fiber is key.

- Yarn Structure: Twisted yarns and tightly woven constructions improve tearing resistance. Loosely woven structures, however, tear easily.

- Fabric Construction: The weave or knitting structure matters significantly. Plain weaves typically have lower tearing strength compared to twill and satin weaves. This is due to their interlocking structures.

- Thread Count: A higher thread count usually increases tearing strength. The material becomes thicker and more resistant to external pressures.

- Finishing Processes: Chemical treatments, coatings, and other finishing operations can either enhance or reduce tearing strength. Some treatments make the material stronger, while others can make it brittle.

I also know that the weave structure greatly influences tear resistance. Factors like warp and weft density, material texture, and the specific weave type are crucial. Higher warp and weft density generally lead to stronger materials due to tighter interweaving. However, excessively high density can sometimes reduce tear strength. This happens by increasing friction and limiting yarn mobility. Plain weave typically shows the lowest tear force. This is because its tight construction restricts yarn movement. In contrast, loose and open constructions, like rib and basket weaves, allow yarns to move and group together. This results in higher tear strength.

Fabric Flexibility and Drape for Movement

Flexibility and drape are essential for comfort and aesthetics. Fabric flexibility is the ease with which a material bends. I know that high friction and resistance to stretching can cause increased pressure on the body. This leads to discomfort. Flexibility also influences the thermal insulation properties of clothing. “Body movement comfort” directly relates to a textile’s ability to allow unrestricted movement.

Drape significantly influences aesthetic appeal. It affects how a garment hangs in graceful folds and conforms to the body. This creates visual beauty. The way a material buckles into rounded folds is a highly desirable characteristic. Beyond just the hang, drape appearance is also shaped by visual effects of light, shade, luster, color, design, and surface decoration. Good draping qualities mean the material adjusts into folds or pleats gracefully and pleasingly. I recognize that subjective factors like fashion, personal preference, and human perception also play a crucial role in assessing drape’s aesthetic impact.

Pilling and Snagging Resistance in Fabric

Pilling and snagging are common issues that affect a material’s appearance and longevity. Pilling occurs when short fibers on the surface tangle into small balls. Snagging happens when loops of yarn are pulled from the surface. I recommend several strategies for improving pilling resistance:

- For Manufacturers:

- Choose high-quality fibers, such as long-staple cotton or combed yarns, for smoother, stronger materials.

- Use tight constructions like dense weaves or tight knitting, to reduce fiber movement.

- Apply anti-pilling finishes, such as cellulase enzyme washes or polymer coatings, to bind fibers.

- Blend materials wisely, for example, 60/40 cotton-poly, for combined softness, strength, and pill resistance.

- Conduct rigorous testing using machines like the Martindale abrasion tester.

- For Consumers:

- Wash garments inside out to reduce friction.

- Use gentle cycles and cold water to protect fibers.

- Avoid overloading washing machines to prevent excessive rubbing.

- Air dry clothes instead of using dryers, which stress fibers.

- Use a fabric shaver to safely remove existing pills.

For snag resistance, I recommend high-tenacity polyester or nylon filaments. These materials have engineered molecular orientation and crystallinity. This provides greater tensile strength and abrasion resistance. Smooth, continuous filament yarns are better than textured yarns. Textured yarns have loops prone to catching and snagging. Continuous filament yarns are single, long, strong threads. They offer a smoother surface, significantly reducing points where snags can start.

Colorfastness and UV Resistance of Fabric

Colorfastness and UV resistance are vital for maintaining a material’s appearance over time. Color fading is a common problem. I know several factors cause it:

- Fume Fading: Nitrogen oxide gases react with certain dyes, causing color changes.

- Water Sensitivity: Some dyes react to water or perspiration, changing color.

- Acid/Alkaline Sensitivity: Dyes can change color when exposed to acidic or alkaline substances.

- Alcohol: It can dissolve certain dyes, leading to permanent color loss.

- Bleach: Various bleaches cause immediate and permanent color loss.

Fluorescent brighteners also contribute to fading. They reflect more blue light, making textiles appear brighter. However, they generally have poor light fastness. When UV radiation breaks them down, they stop fluorescing. This causes the textile to yellow and appear faded. Reactive dyes are sensitive to acids, which can break the dye-fiber bond. Atmospheric pollutants like nitrogen or sulfur oxides produce acids on fiber surfaces. Hot water for laundry and not following care guidelines can also lead to fading. Materials treated with water repellent or other preservative chemicals tend to retain their colors longer.

Fabric Recovery and Shape Retention

Material recovery and shape retention are critical for garments that need to maintain their fit and appearance. Elastic material is engineered to stretch and return to its original state. It does this without changing shape or support. The ‘elastic recovery formula’ dictates how well elastic fibers allow the material to recover after stretching. A higher recovery rate means the garment better returns to its original shape. This prevents sagging or loss of functionality. This property ensures clothing maintains its fit and appearance over time, even with repeated use and movement.

For medical rehabilitation wear, precise elasticity is necessary. It gives the right amount of pressure. It also ensures materials fit without curling or folding. Medical wear requires shape retention for a long period. This supports healing and maintains targeted compression. Fitness apparel, like yoga pants and dance suits, needs materials with a good recovery rate. They remain serviceable without losing shape after continuous use and stretching. Mechanical pre-shrinkage, like Sanforization, helps material retain its shape and achieve good elastic recovery after washing. Chemical cross-linking can also improve cotton’s elastic recovery. It chemically bonds polymer chains, allowing the material to revert to shape after stress.

Tailoring Fabric Durability to Specific Applications

I understand that different applications demand unique durability profiles. There is no one-size-fits-all solution. I always tailor my material choices to the specific end-use. This ensures optimal performance and longevity.

Fabric Requirements for Everyday Apparel

For everyday apparel, I prioritize a balance of comfort, appearance, and resilience. Consider denim for jeans. I know increasing spandex improves comfort but can reduce abrasion resistance and tensile strength. For example, 3% spandex offers approximately 15,000 Martindale cycles for abrasion and 380–420 N tensile strength. However, 5% spandex reduces these to about 13,200 cycles and 350–390 N. Higher spandex also slightly increases pilling risk. I mitigate these trade-offs with stronger cotton yarns or reinforced weaves. For everyday casual wear, I recommend choosing midweight (10-12oz) stretch denim for maximum comfort and durability. I also consider how laundry cycles impact durability. Quick wash cycles, with aggressive spinning, subject materials to intense mechanical stress. This causes premature wear and faded colors. A study by Procter & Gamble and the University of Leeds found that higher wash temperatures and longer cycles significantly increase microfiber shedding and color loss. I advise using gentle cycles for delicate items to preserve quality.

Demands for Performance Fabric Gear

Performance gear requires specific durability properties. For outdoor jackets, I look for reinforced areas, quality zippers, and sturdy stitching. Materials like Gore-Tex offer waterproof yet breathable qualities. Dyneema® provides outstanding cut resistance and strength. Polyester resists stretching, shrinking, and UV damage. Thermoplastic Polyurethane (TPU) offers excellent elasticity and abrasion resistance. I also consider fabric weight for athletic wear.

| Fabric Weight Category | GSM Range | Performance Characteristics & Ideal Activities |

|---|---|---|

| Ultralight Fabrics | 30-80 GSM | High breathability, quick-drying, barely-there feel; ideal for running, cycling, hot weather workouts. Less durable, potentially see-through. |

| Lightweight Fabrics | 80-130 GSM | Suitable for high-intensity activities like long-distance running and hot weather sports. Can be used for whole garments or panels for breathability. |

| Midweight Fabrics | 130-180 GSM | Good balance of breathability, durability, and structure; common for team sports (soccer, athletics, netball, cricket shirts, basketball). May offer compression. |

| Heavyweight Fabrics | 180+ GSM | Prioritizes warmth and durability; suitable for contact sports (rugby, AFL), cold-weather activities, and those requiring extra protection (cricket pants, mountain biking). |

Lighter fabrics generally offer superior breathability. Heavier fabrics are more resistant to wear and tear.

Fabric Considerations for Upholstery and Home Textiles

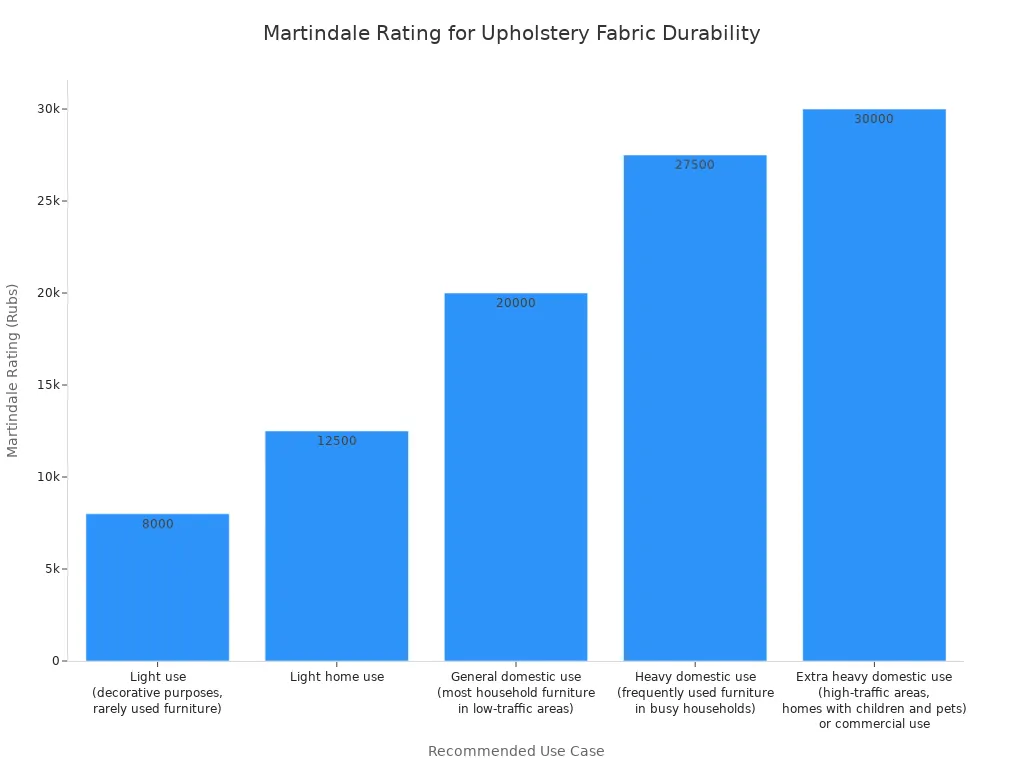

For upholstery, durability is paramount. I rely on tests like the Martindale and Wyzenbeek to measure abrasion resistance. The Martindale test measures rub counts, while the Wyzenbeek test measures double rubs. Both simulate wear and tear.

| Martindale Rating (Rubs) | Recommended Use Case |

|---|---|

| 6,000-10,000 | Light use (decorative purposes, rarely used furniture) |

| 10,000-15,000 | Light home use |

| 15,000-25,000 | General domestic use (most household furniture in low-traffic areas) |

| 25,000-30,000 | Heavy domestic use (frequently used furniture in busy households) |

| 30,000+ | Extra heavy domestic use (high-traffic areas, homes with children and pets) or commercial use |

Tightly woven materials and strong synthetic fibers tend to be more durable. Finishing treatments also enhance overall durability.

Industrial and Protective Fabric Needs

For industrial and protective applications, I focus on extreme conditions. I consider tensile strength for conveyor belts, ensuring they handle heavy loads. Abrasion and chemical resistance are crucial for harsh environments. For protective clothing, I evaluate permeation, degradation, and penetration. Permeation is when a chemical moves through a material at a molecular level. Degradation involves physical changes from chemical exposure. Penetration is the movement of chemicals through non-molecular pathways like seams. No single material protects against all chemicals. I always select materials with the broadest chemical resistance for unknown substances.

I understand durability is a holistic concept for fabric. It involves many properties working together, not just maximum strength. I always select the right fabric by understanding its intended use. This balanced approach ensures optimal performance and value for every application.

FAQ

What is the most important factor for fabric durability?

I believe balanced properties are most important. Maximum strength alone does not guarantee longevity. Instead, I consider a combination of factors like abrasion resistance, tear strength, and flexibility for true durability.

How do I know if a fabric is durable enough for my needs?

I always assess the fabric’s intended use. For example, upholstery needs high abrasion resistance. Performance gear requires specific properties like waterproofness or tear strength. I match the fabric’s characteristics to the application.

Does a higher thread count always mean better durability?

Not always. I find a higher thread count often improves durability and tear strength. However, it can reduce breathability. I balance thread count with other factors like weave type and fiber quality for optimal performance.

Post time: Jan-21-2026