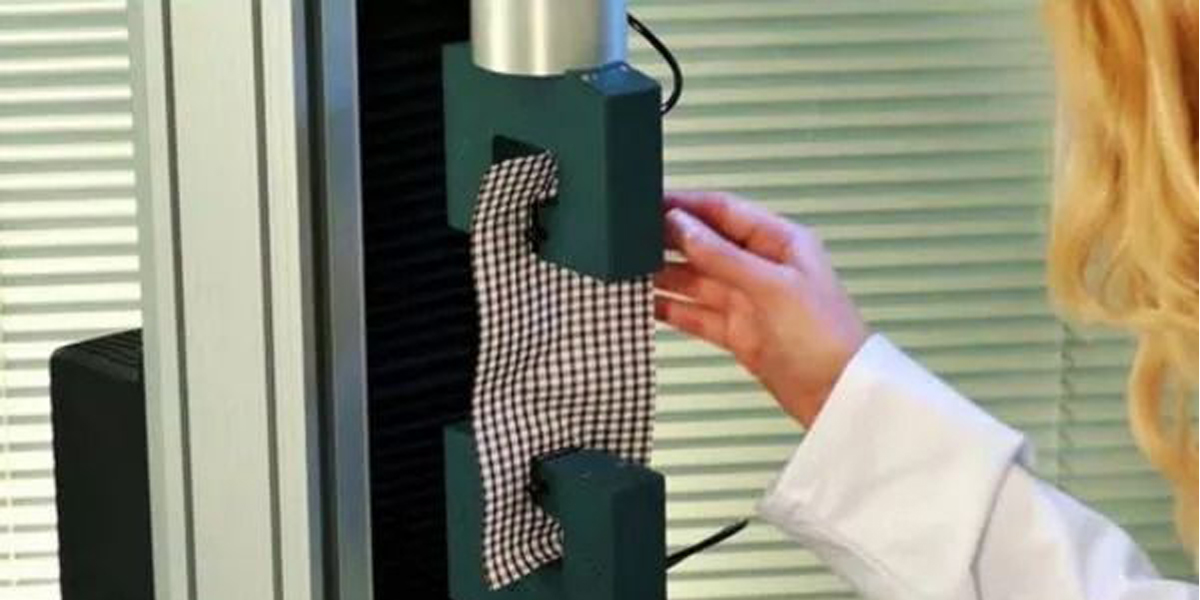

I consider Fabric Testing a strategic imperative. It mitigates potential failures, ensuring product integrity. This proactive approach safeguards against costly issues, preventing reputational damage. Fabric testing directly benefits your business. We uphold strict Fabric testing standards. For instance, scrub uniform fabric testing is crucial. Woven TRSP nurse scrub fabric testing and big plaid school uniform fabric testing exemplify a fabric testing driven textile strategy.

Key Takeaways

- Fabric testing helps businesses avoid problems. It finds issues early to stop costly mistakes.

- Testing protects a brand’s good name. It makes sure products are safe and customers are happy.

- Fabric testing makes sure materials are good. This helps keep the supply chain running smoothly.

Beyond the Numbers: The Limitations of Data in Fabric Testing

Raw Data Alone Doesn’t Reveal Risk

I often see companies focus too much on raw data. They believe numbers alone tell the whole story. However, raw data by itself does not fully reveal risk. Traditional laboratory testing is often time-consuming and costly. It also has an inherently subjective nature. This means the results can vary. The datasets we get from such testing often have limitations. They might lack diversity. They might not represent all textile materials well. This can lead to bias. It can reduce performance when we apply the data to new, unseen materials. I find this a critical point. We need to look beyond just the figures. We must understand what those numbers truly mean for our product’s integrity.

Bridging the Gap Between Lab and Real-World Performance

Bridging the gap between lab results and real-world performance is essential. Lab conditions are controlled. Real-world conditions are not. A fabric might perform well in a lab test. It might fail quickly when customers use it every day. For subjective attributes, like handfeel, the problem is even bigger. We often lack standardized measurement methods. This makes data collection difficult. It limits how well we can predict complex fabric properties. I believe effective Fabric Testing must consider these real-world variables. We need to interpret lab data with practical application in mind. This helps us make better decisions. It ensures our products meet customer expectations.

Fabric Testing: A Core Strategy for Risk Reduction and Supply Stability

Identifying and Preventing Product Failures

I see fabric testing as a critical first step. It helps me identify and prevent product failures before they become costly problems. By testing materials early, I can catch defects. This proactive approach saves time and resources. I know common issues can derail a product. For example, fabric tears, holes, or visible stains are major defects. They affect a garment’s appearance and usability. Shade variations between fabric rolls also lead to defects. Weaving inconsistencies, like holes or thin spots, are fabric quality issues. Fabric shrinkage after washing, due to improper pre-treatment, is a common cause of garment defects. I use fabric testing to pinpoint these problems. This ensures I only use high-quality materials in my products.

Protecting Brand Reputation and Customer Trust

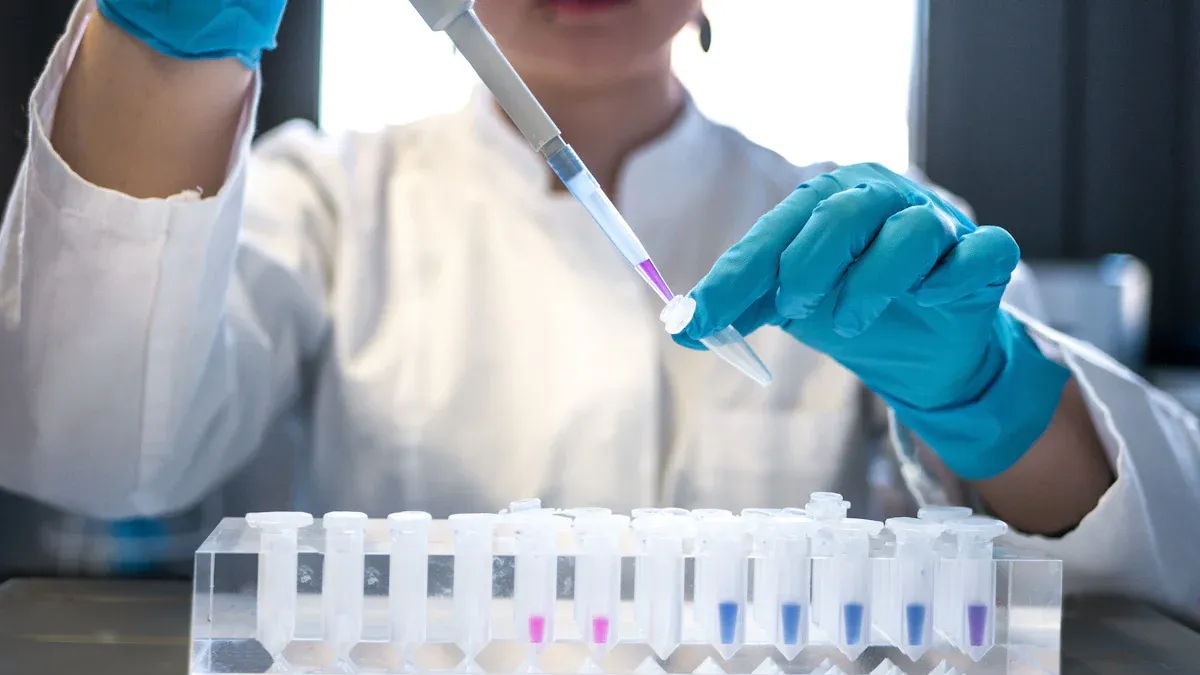

I believe protecting my brand’s reputation is paramount. Fabric testing directly contributes to this goal. It ensures product integrity and regulatory compliance. This helps me prevent costly recalls. It safeguards my brand’s image. Lab testing evaluates physical, chemical, and mechanical properties. This ensures my products meet quality and safety standards. This activity prevents costly reworks and compliance issues. It also prevents customer dissatisfaction. All these factors are crucial for maintaining a brand’s image. Quality control is key. Lab testing identifies potential defects early. This is vital for building and maintaining my brand’s reputation. Compliance is also important. It ensures products meet international standards, like ISO, ASTM, or Oeko-Tex. This prevents legal issues and allows market access. It protects my brand’s credibility. Reducing the risk of reworks is another benefit. Early detection of defects through proper testing protocols reduces the need for product recalls. It also lowers associated rework costs. Recalls and reworks can severely damage brand reputation.

Minimizing Financial Losses and Legal Liabilities

I understand the financial implications of product failure. Fabric testing helps me minimize financial losses. It also reduces legal liabilities. When I catch defects early, I avoid expensive rework. I prevent product recalls. These issues can cost a business a lot of money. They can also lead to lawsuits. By ensuring my fabrics meet all quality and safety standards, I reduce the risk of legal action. This proactive stance protects my company’s bottom line. It gives me peace of mind.

Ensuring Compliance and Market Access

I know compliance is not optional. Fabric testing is essential for ensuring my products meet all necessary regulations. It helps me gain market access. Different markets have different standards. My testing protocols confirm my materials comply with these specific requirements. This prevents delays at customs. It avoids rejection from retailers. It ensures my products can reach customers globally. This opens up new opportunities for my business.

Enhancing Supply Chain Stability Through Fabric Testing

I find fabric testing crucial for a stable supply chain. It helps me identify potential issues with material quality early. This happens in the production cycle. It ensures fabrics meet specified standards and performance requirements. By preventing the use of substandard materials, fabric testing reduces the likelihood of product recalls, rework, and delays. This proactive approach minimizes disruptions. It prevents problems caused by quality-related issues in the supply chain. I can trust my suppliers more. I know their materials meet my strict standards. This creates a more reliable and efficient production process.

Shifting the Mindset: Proactive Fabric Testing for Business Advantage

Integrating Testing Across the Product Lifecycle

I advocate for integrating Fabric Testing throughout the entire product lifecycle. I believe this approach starts with initial design and material selection. It continues through prototyping, production, and even post-market analysis. Early-stage testing allows me to identify potential material weaknesses or performance issues. This happens before significant investment occurs. During production, I conduct in-process checks. These checks ensure consistency and adherence to specifications. This continuous vigilance minimizes surprises. It also reduces the likelihood of costly late-stage failures. I see this as a proactive strategy. It builds quality into the product from its very inception.

Focusing on “Fitness for Purpose” in Fabric Testing

My focus in Fabric Testing is always on “fitness for purpose.” I understand that a fabric’s performance requirements vary greatly depending on its intended end-use. For example, a fabric for outdoor performance wear demands rigorous testing for water resistance, breathability, and abrasion. A fabric for interior upholstery, however, requires different tests for durability, colorfastness, and flame retardancy. I tailor my testing protocols to these specific applications. This ensures the fabric not only meets general standards but also performs optimally in its real-world environment. This targeted approach guarantees customer satisfaction. It also prevents over-engineering or under-testing.

Interpreting Results Through a Risk Lens

I interpret all test results through a critical risk lens. A simple “pass” or “fail” mark does not tell the whole story. I evaluate the degree of compliance or non-compliance. I consider the potential impact of any deviation. For instance, a slight variation in colorfastness might be a minor aesthetic concern for one product. It could be a significant brand reputation risk for another. I assess the likelihood of a failure occurring in actual use. I also weigh the severity of its consequences. This comprehensive risk assessment guides my decision-making. It allows me to prioritize actions. It helps me allocate resources effectively. I make informed choices that protect my business and my customers.

I see Fabric Testing as an indispensable tool for strategic risk management. I shift my focus from mere numerical compliance. I prioritize proactive risk identification and mitigation. This ensures product quality, protects my brand, and builds lasting customer loyalty. I believe in foresight, not just figures. This leads to greater confidence and profitability.

FAQ

Why do I focus on risk, not just numbers, in fabric testing?

I believe numbers alone do not show true risk. I interpret data to understand potential failures. This helps me prevent costly issues.

How does fabric testing protect my brand’s reputation?

I use testing to ensure product quality and safety. This prevents recalls and customer dissatisfaction. It builds trust and safeguards my brand image.

Can fabric testing really improve my supply chain stability?

Yes, I use testing to identify material issues early. This prevents disruptions from poor quality. It ensures a reliable and efficient production process.

Post time: Jan-09-2026