In today’s market, I notice that professional brands fabrics prioritize higher fabric standards more than ever. Consumers increasingly seek sustainable and ethically sourced materials. I see a significant shift, where luxury brands set ambitious sustainability goals, pushing professional fabric suppliers to innovate. This trend leads to a demand for eco-friendly textile suppliers who can meet these rising expectations, particularly in the realm of fabric innovation 2025. Additionally, the popularity of linen look fabrics is on the rise, further emphasizing the need for a reliable fabric manufacturer for brands that can deliver quality and sustainability.

Key Takeaways

- Consumers now prioritize durability, repairability, and quality in fabrics, pushing brands to focus on long-lasting products.

- Sustainability is key; brands must adopt eco-friendly materials and transparent practices to meet rising consumer expectations.

- Technological advancements in fabric production enhance quality and sustainability, giving brands a competitive edge in the market.

Evolving Consumer Expectations

As I observe the fabric market, I notice a significant shift in consumer expectations. Today’s consumers prioritize durability, repairability, and overall quality in fabrics. This change stems from dissatisfaction with low-quality, fast-fashion garments. Many consumers now seek products that last longer and can withstand the test of time.

Key Consumer Demands:

- Durability: Shoppers want fabrics that endure wear and tear.

- Repairability: There is a growing interest in items that can be easily mended.

- Quality: Consumers increasingly value craftsmanship over quantity.

This evolution in expectations aligns with a broader trend toward secondhand clothing. Many consumers are embracing pre-owned garments, which often showcase better craftsmanship. This shift offers brands a unique opportunity to differentiate themselves by focusing on quality and service. By doing so, they can justify higher prices while meeting consumer demands.

I also find that consumers are willing to pay more for higher-quality fabrics. A recent study revealed several factors influencing this willingness to pay (WTP):

| Factor Influencing WTP | Effect on Purchase Intention |

|---|---|

| Environmental Concern | Positive |

| Perceived Value | Positive |

| Direct Experience | Varies by eco-material |

| Indirect Experience | Varies by eco-material |

| Socio-demographic Characteristics | Strongly dependent |

Younger generations, particularly Gen Z and Millennials, lead this charge. They prioritize sustainability in their clothing consumption habits. In fact, 90% of Gen Z consumers purchased sustainable products in 2022, compared to 85% of Millennials. Notably, 39% of Gen Z and 42% of Millennials are willing to pay more for sustainable products. This contrasts sharply with only 31% of Generation X and 26% of Baby Boomers.

As I look ahead to 2025, I see several common demands related to fabric sustainability:

- Circular Fashion: Consumers focus on longevity, reuse, and closed-loop systems.

- Transparency: Shoppers want to know the origins of their clothing, prompting brands to adopt supply chain transparency.

- Eco-Friendly Materials: The use of sustainable textiles like organic cotton and recycled polyester is on the rise.

- Minimalism: A shift towards a ‘buy less, choose well’ mindset encourages investment in high-quality, timeless pieces.

Sustainability and Ethical Production

In my exploration of the fabric industry, I see a growing emphasis on sustainability and ethical production. Professional brands recognize that consumers are increasingly aware of the environmental and social impacts of their purchases. This awareness drives brands to adopt more responsible practices in their sourcing and production processes.

I find that upwards of 65-70% of consumers under 35 prioritize ethical practices when choosing brands. This statistic highlights the importance of transparency and accountability in the fabric supply chain. Brands that fail to address these concerns risk losing a significant portion of their customer base.

To meet these consumer demands, many professional brands are turning to sustainability certifications. These certifications serve as benchmarks for ethical production and environmental responsibility. Here are some leading certifications that brands often seek:

| Certification Name | Accredited By | Used For | Examples of Brands |

|---|---|---|---|

| Global Organic Textile Standard (GOTS) | GOTS and third-party GOTS-accredited certification bodies | Textiles | PACT, Organic Basics, Brook There |

| Responsible Wool Standard (RWS) | Textile Exchange | Wool products | Patagonia, H&M, REI, ASKET |

| ZQ Merino Wool Certified | The New Zealand Merino Company (NZM) | Wool farms | Allbirds, Smartwool, Fjällräven |

| Better Cotton Initiative (BCI) | Better Cotton Initiative (BCI) | Brands | H&M, ASOS, Urban Outfitters |

| OEKO-TEX® | N/A | Textiles and fabrics | N/A |

| Bluesign | N/A | Clothes, textiles | N/A |

These certifications not only assure consumers of the ethical practices behind their favorite brands but also encourage manufacturers to improve their processes. I have seen firsthand how brands are incorporating recycled materials into their fabric production. For instance, one leading brand aims to ensure that all cotton, linen, and polyester used in products is organic, sustainable, or recycled by 2025. Another brand has set a target to use 100% recycled or sustainable materials by 2030.

The environmental impacts of traditional fabric production are significant. For example, conventional cotton farming requires about 2,700 liters of water to produce just one T-shirt. In contrast, sustainable fabrics like organic cotton and linen use significantly less water. Here’s a comparison of the environmental impacts of traditional versus sustainable fabrics:

| Aspect | Traditional Fabrics | Sustainable Fabrics |

|---|---|---|

| Water Consumption | Requires large amounts of water; e.g., 2,700 liters for one cotton T-shirt. | Uses significantly less water; e.g., organic cotton and linen are more water-efficient. |

| Chemical Usage | Involves heavy use of pesticides and synthetic dyes, leading to pollution. | Utilizes natural or low-impact dyes, reducing harmful chemical release. |

| Energy Consumption | Energy-intensive production, especially for synthetics like polyester. | Generally requires less energy; some processes use renewable energy sources. |

| Waste Generation | Contributes to significant waste; synthetic fabrics can take centuries to decompose. | More likely to be biodegradable and compostable, leaving minimal landfill impact. |

| Impact on Biodiversity | Conventional farming harms ecosystems due to pesticide use. | Practices support biodiversity and soil health through organic farming methods. |

Regulatory changes are also reshaping fabric standards for professional brands. New compliance requirements focus on sustainability and safety, including restrictions on harmful chemicals and mandates for recycling initiatives. For instance, the EU is revising its regulations to enhance fiber identification and introduce sustainability labels. These changes directly influence how brands source and market their fabrics.

However, challenges remain. The textile industry is the second-largest polluter globally, and brands often face price-driven motivations that prioritize cost over sustainability. The logistics sector for textiles involves a complex network of global supply chains, which can lead to high greenhouse gas emissions.

To overcome these challenges, professional brands collaborate closely with suppliers. They look for sustainability credentials, such as certifications like GOTS and Oeko-Tex, to ensure environmental and social standards. Transparency and traceability are also crucial, as brands choose suppliers that provide detailed information about their production processes.

Technological Advancements in Fabric Production

In my exploration of fabric production, I see that technological advancements play a crucial role in enhancing the quality of materials for professional brands. Innovations like antimicrobial additives help fabrics resist bacterial growth, keeping them fresh and extending their lifespan. This improvement not only benefits consumers but also supports sustainability by reducing waste.

I also notice a shift towards new plant-based textiles. These materials, derived from cultivated plants and waste products, enhance sustainability in textile manufacturing. Greater customization options have emerged due to advances in manufacturing technologies. Brands can now offer unique designs that cater to individual preferences, making high-quality fabrics more accessible.

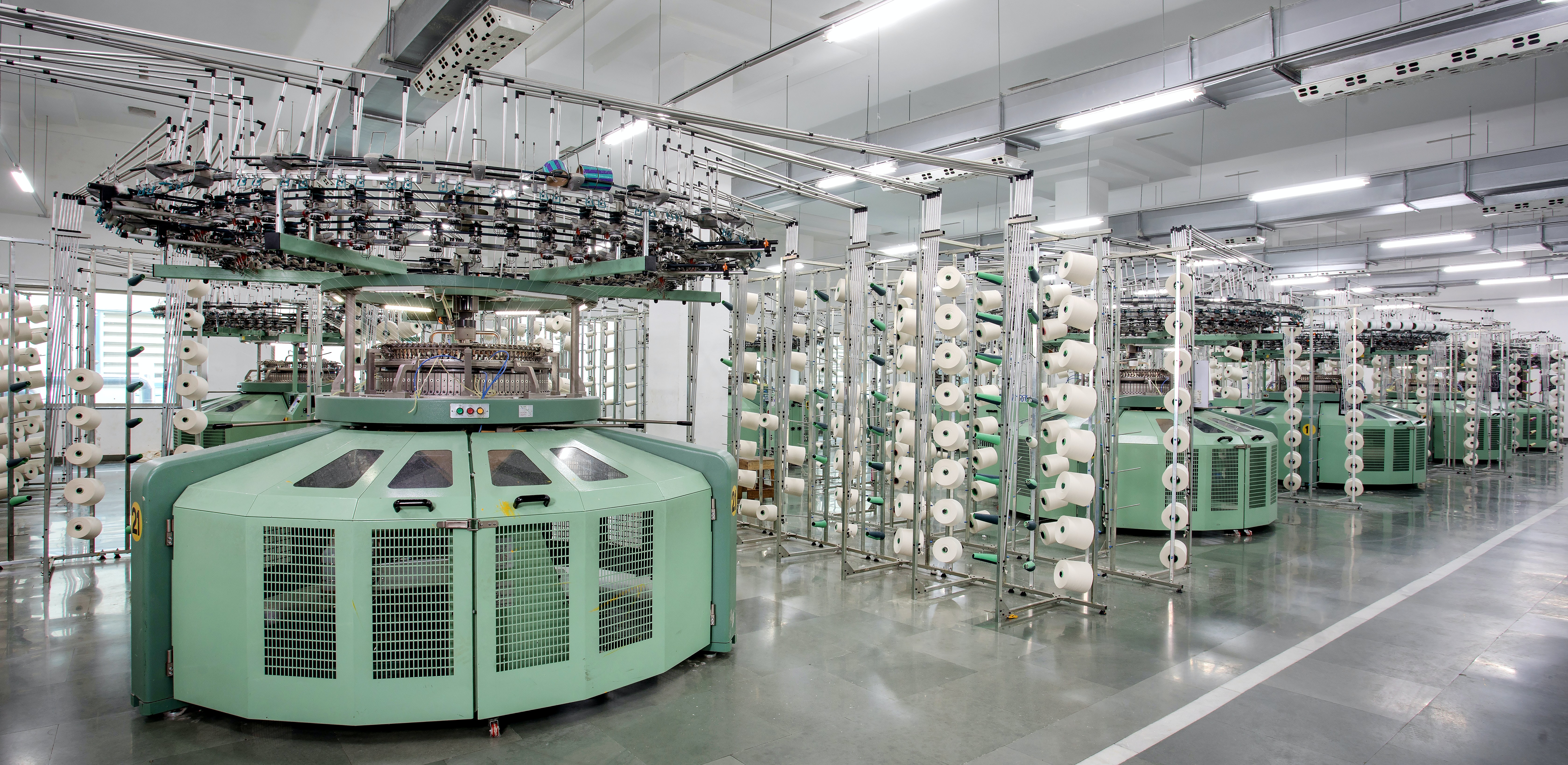

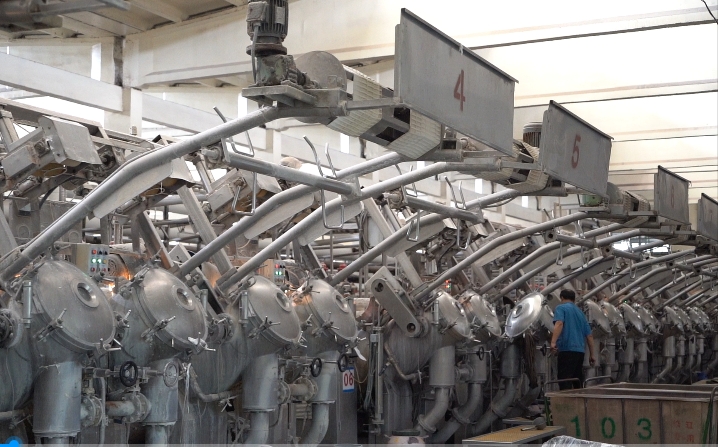

Automation has transformed the production process. Machines maintain uniform tension and thickness, leading to higher-quality products. Automated systems quickly detect defects, minimizing variations and ensuring consistency. This precision boosts customer satisfaction and strengthens brand reputation.

Smart textiles are another exciting development. They integrate electronic components into traditional fabrics, offering functionalities like temperature regulation and health monitoring. These textiles adapt to environmental changes, meeting modern consumer demands for innovation.

Overall, these technological advancements empower professional brands to meet higher fabric standards while enhancing sustainability and quality.

Competitive Advantage

In my experience, higher fabric standards provide professional brands with a significant competitive advantage. Brands that prioritize quality often see enhanced customer satisfaction and loyalty. For instance, I admire how Lululemon innovates with patented fabrics. This strategy not only ensures exclusivity but also keeps customers engaged and interested in their products. The introduction of technical fabrics that wick away sweat positions Lululemon as a leader in the athleisure market, attracting consumers who prioritize performance.

Several case studies illustrate the impact of superior fabric quality on brand reputation and sales. Patagonia’s “Worn Wear” campaign promotes garment repair, emphasizing durability and sustainability. This storytelling approach resonates with consumers. Eileen Fisher shares its supply chain and sustainability goals transparently, supported by customer testimonials. Everlane uses high-definition videos to showcase factory conditions and fabric quality, fostering trust. Reformation engages younger audiences via social media, sharing sustainability metrics and behind-the-scenes content interactively.

To differentiate themselves, brands often adopt various standards. For example, Fair Trade ensures transparency in product composition, while ECO PASSPORT by OEKO-TEX identifies chemicals used in textiles. These certifications enhance product safety and quality, giving brands a distinct edge in the market. By focusing on these aspects, professional brands fabrics can build a strong reputation and attract a loyal customer base.

Professional Brands Fabrics: Quality and Consistency

In my experience, maintaining quality and consistency in fabrics is vital for professional brands. I have seen how brands establish clear guidelines to ensure their products reflect their identity. These guidelines help in selecting materials that align with brand values, which is crucial for delivering quality.

To achieve consistency across product lines, I recommend the following steps:

- Establish a standardized size chart to avoid deviations in fit.

- Conduct sample garment fittings with diverse body types to identify size issues.

- Collect consumer feedback from different regions to optimize size settings.

- Perform regular fit audits with professionals to ensure consistency across sizes.

Quality control processes play a significant role in ensuring high fabric standards. I have observed that effective quality control includes rigorous checks at various stages, from fabric selection to final assembly. Key considerations involve:

- Material selection to ensure fabrics meet standards for strength and texture.

- Production monitoring with regular inspections during cutting and sewing.

- Standardized testing for seam strength and shrinkage to validate garment quality.

Common fabric defects can undermine a brand’s reputation. I often encounter issues like defective stitches, open seams, and color shading. Addressing these defects requires attention to detail during production. For instance, I have found that inspecting fabric under consistent lighting helps identify color discrepancies early.

By focusing on quality and consistency, professional brands can build trust and loyalty among consumers, ensuring long-term success in a competitive market.

In my view, adapting to higher fabric standards is essential for professional brands aiming for future success. Brands that prioritize quality not only meet consumer demands but also enhance their market competitiveness.

Key Benefits of Higher Fabric Standards:

- Compliance with new regulations secures vital contracts.

- Investing in quality control boosts profit margins.

- Technological integration enhances efficiency and competitiveness.

As I look ahead, I see that brands must embrace these changes to thrive in an evolving market landscape.

FAQ

What are the key benefits of using higher fabric standards?

Higher fabric standards ensure durability, sustainability, and consumer trust. They also enhance brand reputation and can lead to increased sales.

How can brands ensure fabric quality and consistency?

Brands can implement strict quality control processes, conduct regular inspections, and establish clear guidelines for material selection and production.

Why is sustainability important for fabric production?

Sustainability reduces environmental impact, meets consumer demand for ethical practices, and helps brands comply with evolving regulations in the textile industry.

Post time: Sep-16-2025