When sourcing waterproof fabrics, many buyers encounter the same frustrating situation:

two suppliers describe their fabrics as “waterproof,” yet the prices can differ by 30%, 50%, or even more.

So where does this price gap really come from?

And more importantly—are you paying for real performance, or just a label?

This article breaks down the hidden factors behind waterproof fabric pricing, helping you make informed decisions instead of costly assumptions.

What Does “Waterproof” Really Mean in Fabrics?

One of the biggest reasons for price confusion is the misuse of the word waterproof.

In reality, waterproof performance exists on a spectrum:

-

Water-repellent: Treated to resist light rain for a short time

-

Water-resistant: Can withstand limited water exposure

-

Waterproof: Tested to resist water penetration under pressure (measured in mmH₂O)

Two fabrics may both be marketed as “waterproof,” yet their actual performance, durability, and lifespan can be completely different.

The Main Waterproof Technologies That Affect Cost

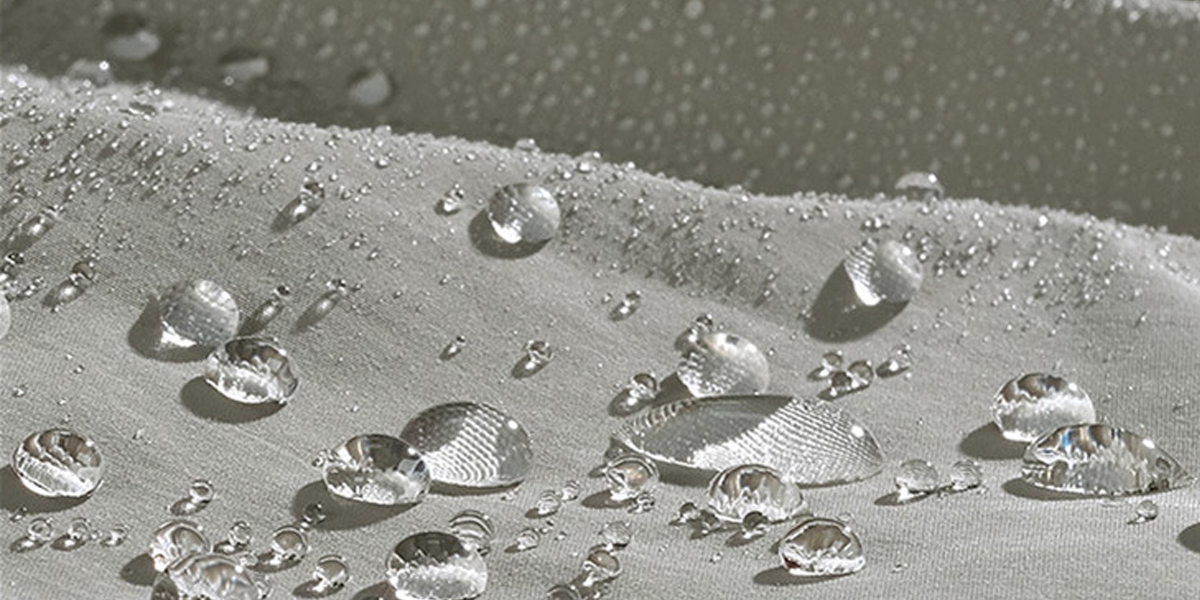

1. Chemical Coatings (PU, PVC, DWR)

This is one of the most common and cost-effective waterproof solutions.

-

PU or PVC coatings applied to fabric surface

-

DWR (Durable Water Repellent) added for surface beading

-

Lower initial cost, wide application range

However, coating quality, thickness, and formulation vary greatly.

Low-cost coatings may lose waterproof performance after washing or crack over time.

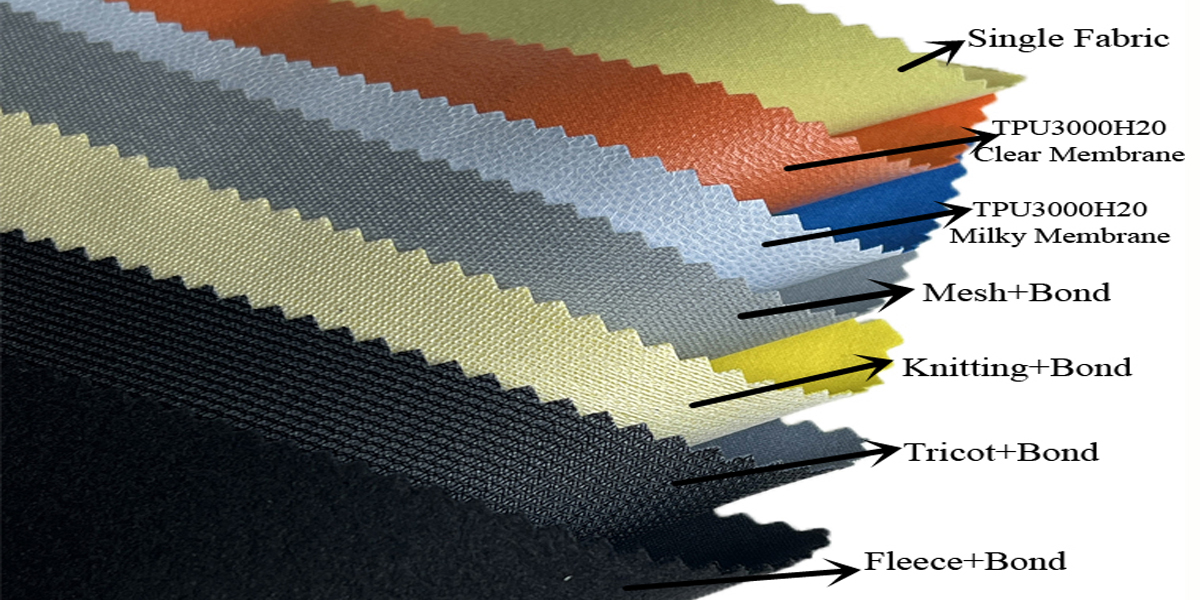

2. Laminated Membranes (TPU, PU Membrane, PTFE)

Membrane laminations significantly increase cost—but also performance.

-

Higher waterproof ratings

-

Better durability and wash resistance

-

Improved breathability when engineered correctly

This technology is often used in outdoor jackets, workwear, and high-performance garments, where consistent waterproof protection is critical.

3. Structural or Yarn-Level Waterproofing

Some fabrics achieve water resistance through yarn selection, weave density, and fabric construction.

-

Requires advanced weaving control

-

Higher production cost

-

Often combined with coatings or membranes for best results

This approach is less visible but plays a major role in long-term performance.

Key Factors That Create Big Price Gaps Between Suppliers

Here’s what usually drives the difference between a low quote and a higher one:

-

Raw material quality (resins, membranes, base fabric)

-

Coating thickness and uniformity

-

Waterproof rating and real test results

-

Wash durability and hydrolysis resistance

-

Production equipment and process stability

-

Environmental compliance (PFAS-free, REACH, GRS)

-

Batch-to-batch consistency

Many low-priced fabrics perform well in the lab—but fail in real production or after repeated washing.

Why Some Low-Priced Waterproof Fabrics Fail in Real Use

Common issues buyers report include:

-

Coatings peeling or cracking

-

Waterproof performance dropping after 5–10 washes

-

Fabric stiffening or yellowing

-

Color inconsistency between batches

These problems rarely show up in initial samples but appear during bulk production or end use—when costs are much harder to control.

How to Evaluate Waterproof Fabric Quotes Like a Professional Buyer

Instead of comparing price alone, ask suppliers for:

-

Waterproof rating (mmH₂O) and test standards

-

Wash durability data

-

Application recommendations

-

Fabric construction details

-

Compliance certificates

-

Production lead time and MOQ clarity

A transparent supplier will explain why their fabric costs what it does.

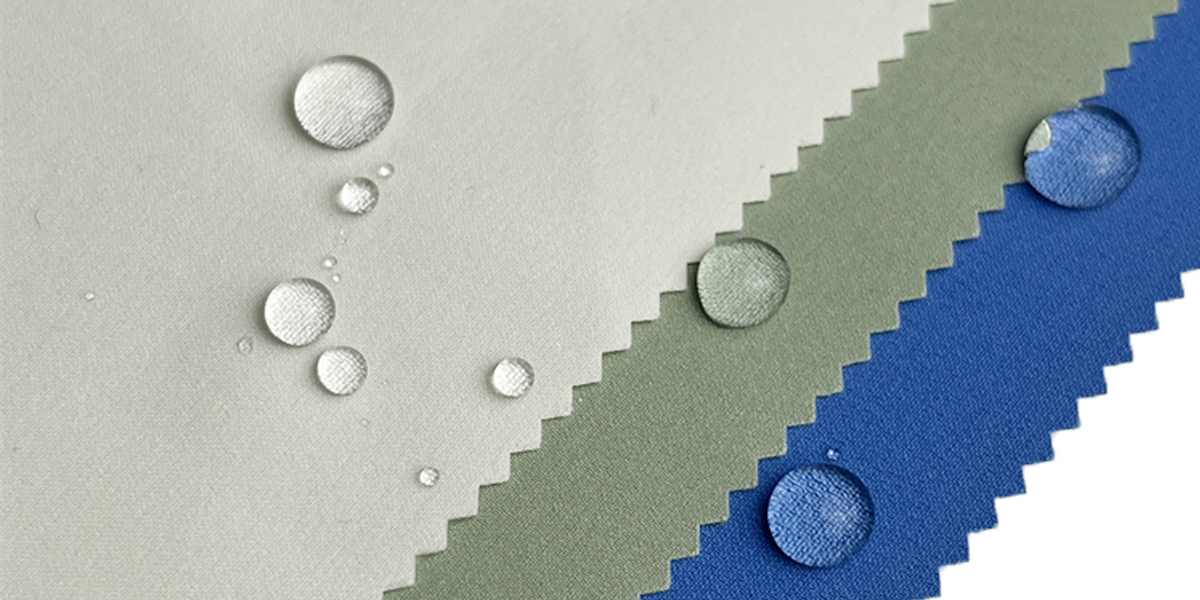

Matching Waterproof Performance to the Right Application

Not every garment needs the highest waterproof rating.

-

Light outerwear or fashion pieces may only need water repellency

-

Workwear and uniforms require durable waterproof protection

-

Medical or outdoor garments demand consistency and compliance

The best sourcing decision balances performance, durability, and cost—based on real end use.

Conclusion: Paying for Performance, Not Just a Label

Large price differences in waterproof fabrics are rarely accidental.

They reflect differences in technology, materials, process control, and long-term reliability.

Understanding these factors allows you to invest in fabrics that protect your brand, your customers, and your margins—rather than chasing the lowest initial quote.

Post time: Dec-23-2025