I find that yarn-dyed fabrics offer intricate patterns and visual depth, making them ideal for brands that prioritize unique aesthetics and excellent woven polyester rayon fabric color consistency. Piece-dyed fabrics, on the other hand, provide cost-effective solid colors and greater production flexibility. As a consultant to a luxury office uniform textile supplier, I advise on their fabrics dyeing process, emphasizing that the choice between Yarn-Dyed vs Piece-Dyed fabrics significantly impacts their long term fabric customization supply, especially for premium woven viscose polyester blended fabric.

Key Takeaways

- Yarn-dyed fabrics offer rich patterns and strong color. They are good for brands that want unique designs and lasting color.

- Piece-dyed fabrics are cheaper and faster for solid colors. They give brands more freedom to change colors quickly.

- Choose the dyeing method that fits your brand’s goals. Consider design, budget, and how fast you need to make products.

Understanding Yarn-Dyed Fabrics Dyeing Process

Definition and Production Process

I define yarn-dyed fabrics as textiles where I dye individual yarns before weaving them into fabric. This process contrasts with dyeing the entire fabric piece after weaving. For cotton fabrics, the yarn-dyeing process involves several precise steps. First, I pretreat the raw yarn. This includes winding it onto perforated packages, ensuring even dye absorption. Then, I scour and bleach the yarn with chemicals like Sodium Hydroxide to remove natural waxes. Next, I prepare the dyebath with water, dyes, and auxiliary chemicals. I circulate this dyebath to ensure consistent concentration. I heat the dyebath to a specific temperature, holding it for dye penetration. Finally, I add fixing agents to bond the dye to the yarn. After dyeing, I rinse and neutralize the yarn. I also soap it for colorfastness and apply finishing agents. I then unload and dry the yarn packages. This meticulous fabrics dyeing process ensures deep color saturation.

Key Advantages for Brands

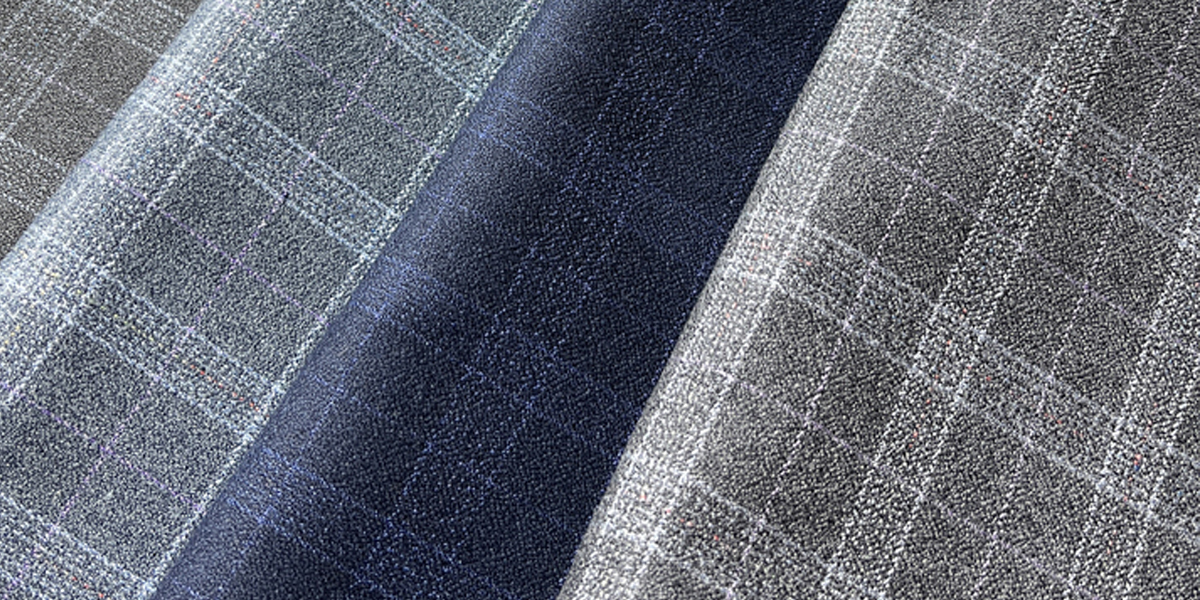

Yarn-dyed fabrics offer significant advantages for brands. I find they provide superior colorfastness. The dye deeply fixes within the fibers because I dye the yarn before weaving. This makes the fabrics less prone to fading from washing or light. They maintain their vibrant appearance over time. This method also allows for incredible pattern intricacy. I can create rich color combinations and complex patterns by interweaving warp and weft yarns of different colors. This enables diverse effects like plaids, stripes, and jacquards. The uniform and distinct color distribution offers extensive creative possibilities for design.

Key Disadvantages for Brands

Despite the benefits, yarn-dyed fabrics present some challenges. I often encounter high Minimum Order Quantities (MOQs). This forces brands, especially smaller ones, to make large purchases. It increases initial spending and the risk of excess stock. This also reduces financial flexibility. I also face delays and long lead times. These can stall production and push back launch dates. Even short delays can result in missing seasonal opportunities. Furthermore, the yarn-dyeing process has environmental impacts. It uses significant amounts of water. It also generates wastewater containing synthetic chemicals and dyes. These can contaminate water bodies and affect ecosystems.

Understanding Piece-Dyed Fabrics Dyeing Process

Definition and Production Process

I define piece-dyed fabrics as textiles where I dye the entire fabric roll after weaving. This method offers a different approach compared to dyeing individual yarns. For polyester fabrics, I follow a specific fabrics dyeing process. First, I pre-wash the fabric with a mild detergent to remove any finishes or dirt. I rinse it thoroughly and let it dry. Then, I set up my work area, ensuring good ventilation and covering surfaces to prevent spills. I always wear gloves and an apron for protection. For the disperse dye method, I bring water to a boil in a stainless steel pot and add the disperse dye, stirring well. I immerse the polyester fabric, making sure it is fully submerged, and maintain a rolling boil. I constantly stir the fabric to ensure even dye uptake. After achieving the desired color, I rinse the dyed fabric in warm water and gradually cool it down to set the dye.

Key Advantages for Brands

Piece-dyed fabrics offer significant advantages for brands, especially regarding cost and speed. I find this method is the most cost-effective choice for large-volume orders. It streamlines processes, reduces labor, and lowers machine setup costs. I can purchase greige goods in bulk, which gives me better pricing. This optimizes the dyeing process for mass production, leading to a lower price per meter. Piece-dyeing also provides unparalleled flexibility in color matching. I can easily adjust dye formulas for specific shades and run sample lots. This method is ideal for items where cost and speed-to-market are crucial, like basic apparel or uniforms. It allows for quick responses to color trends. I can dye fabric in popular colors just before final product assembly, after initial production as undyed material. This flexibility means I can make color decisions later, avoiding overproduction of unpopular colors and achieving faster turnaround times.

Key Disadvantages for Brands

Despite the benefits, piece-dyed fabrics present some challenges, particularly with color consistency and depth. I often encounter manufacturing variations. Minor deviations in temperature control, dyeing techniques, or chemical compositions can lead to noticeable color differences between fabric batches. For example, temperature affects dye interaction, and variations in chemical concentrations impact dye uptake. Inconsistent lighting conditions also significantly affect color perception. A fabric appearing consistent in natural daylight might look different under artificial lighting due to metamerism. This makes accurate color evaluation difficult without standardized lighting. Furthermore, human observation introduces subjectivity. Individual differences in visual acuity, color vision, or even fatigue can lead to inconsistencies in color assessments and matching, especially when multiple individuals are involved in the process.

Buyer Decision Perspective: Yarn-Dyed vs. Piece-Dyed

Visual Depth and Aesthetic Appeal

I observe a significant difference in visual depth and aesthetic appeal between yarn-dyed and piece-dyed fabrics. Yarn-dyed patterns produce solid, uniform colors with a clean look. I find them ideal for creating intricate designs like stripes or checks by weaving different colored yarns together. This method allows for a rich, complex visual texture.

In contrast, piece-dyed colors result in a flat, uniform color. They often lack the depth and variation I see in other dyeing methods. I consider them ideal for basic, high-volume products where cost and speed are priorities. However, when I look at top-dyed yarn, a type of fiber dyeing, it creates a rich, complex, and subtle marl or melange effect. This offers unparalleled depth of color, often described as having a painterly quality. I find this best for premium knitwear and luxury products. Consumers perceive top-dyed sweaters as long-lasting, visually rich, and aesthetically calm. These features are increasingly favored in timeless wardrobe staples. The rich, nuanced aesthetic of top-dyed yarn immediately stands out in a market of solid-colored garments. It conveys a sense of high-end quality and craftsmanship. This subtle color variation, with a depth that feels almost ‘painterly,’ cannot be replicated with other methods. It makes top-dyed yarn a hallmark of high-end premium knitwear.

Reorder Stability and Consistency

When I consider reorder stability and consistency, yarn-dyed fabrics generally offer a more predictable outcome. Because I dye the yarns before weaving, the color consistency across different production runs tends to be higher. This is crucial for brands that rely on maintaining precise color standards for their signature products. With piece-dyed fabrics, I sometimes encounter challenges with batch-to-batch color variations. Even minor differences in the dyeing bath or process can lead to noticeable shade discrepancies. This requires careful monitoring and quality control to ensure acceptable consistency for subsequent orders.

Minimum Order Quantity (MOQ) Implications

Minimum Order Quantity (MOQ) is a critical factor for brands. I find that yarn-dyed fabrics typically come with higher MOQs. This is because the specialized dyeing of individual yarns before weaving requires more setup and a larger commitment from the mill. Brands must often order substantial quantities to make the production run economically viable. For piece-dyed fabrics, MOQs are generally lower. I can often purchase greige (undyed) fabric in smaller quantities and then dye it to the desired color. This flexibility benefits smaller brands or those testing new colorways.

Cost Efficiency and Budget Considerations

Cost efficiency is always a primary concern. I see piece-dyed fabrics as the more cost-effective option, especially for large-volume orders of solid colors. The simpler fabrics dyeing process, which involves dyeing entire rolls of fabric, streamlines production and reduces labor costs. This leads to a lower price per meter. Yarn-dyed fabrics, with their intricate pre-dyeing process and higher MOQs, typically incur greater costs. Brands must weigh the premium aesthetic and durability of yarn-dyed fabrics against the higher investment.

Production Flexibility and Lead Times

Production flexibility and lead times significantly impact a brand’s ability to respond to market trends. I know that yarn-dyed fabrics generally take much longer to produce. The average production lead time for CVC yarn-dyed fabric orders ranges from 10 to 21 days, depending on order size and customization. This longer lead time requires brands to plan further in advance. Piece-dyed fabrics offer greater flexibility and shorter lead times. I can dye greige fabric quickly to meet immediate demand or respond to emerging color trends. This allows brands to make color decisions later in the production cycle, reducing the risk of overstocking unpopular colors and enabling faster turnaround times.

Strategic Selection Framework for Brands

When Yarn-Dyed is the Optimal Choice

I find yarn-dyed fabrics are the optimal choice for brands prioritizing intricate designs and superior color integrity. I recommend this method for products where visual depth and a premium feel are essential. For example, I see yarn-dyed as ideal for creating multi-colored patterns, checks, and stripes. These designs are woven directly into the fabric. I often specify yarn-dyed for specific yarns like wool yarns, acrylic knitting yarns, and fancy yarns. It also works well for woven shirting yarns, knitwear, and blended yarns. I use it for warp yarns in woven fabrics. The end products benefiting most include knitting yarns, carpets, upholstery, and decorative fabrics. For woven fabrics, I choose yarn-dyed for checks, stripes, and dobby designs. I also select it for patterned knits, such as stripes and jacquards. This method ensures the patterns are deeply embedded and long-lasting.

When Piece-Dyed is the Optimal Choice

I consider piece-dyed fabrics the optimal choice when brands need cost-effectiveness, speed, and flexibility. This method works best for solid colors or simple designs. I often recommend it for basic garments, linings, and T-shirts. These products require quick turnaround times or lower costs. Piece-dyeing allows brands to respond quickly to fashion trends. They can produce smaller, custom batches with different colors. This flexibility helps brands avoid overstocking unpopular colors. It also enables faster production cycles. I find it particularly useful for items where color decisions can be made later in the production process.

Aligning Dyeing Method with Brand Identity

I believe the choice of dyeing method significantly influences a brand’s perceived value and market positioning. It is crucial to align the dyeing technique with your brand’s identity. For instance, a luxury skincare brand in South Korea saw a 15% increase in perceived product value. This happened when their box liner featured navy silk with matte gold stamping. This was compared to the same packaging in white cotton. Similarly, a Danish chocolatier used soft-finished burgundy Mulberry silk as an inner wrap. This led 35% of customers to keep the silk as a keepsake. This shows how tactile experiences from dyeing and finishing can extend brand value.

I also observe how different dyeing techniques convey specific brand perceptions:

| Dyeing Technique | Appearance & Brand Perception | Environmental Impact | Brand Application |

|---|---|---|---|

| Reactive Dyeing | Bright, fade-resistant, signals high-volume luxury | Moderate | High-volume luxury |

| Natural Dyeing | Earthy, organic, story-rich, conveys artisan & sustainable luxury | Low | Artisan & sustainable luxury |

| Acid Dyeing | Sharp tones, fast absorption, suitable for fashion & accessories | Moderate–High | Fashion & accessory packaging |

| Botanical Printing | Unique prints from actual plants, suggests handmade, limited edition | Low | Handmade, limited edition sets |

The dyeing and finishing techniques applied to silk are crucial. They shape a customer’s perception of a luxury brand. Elements like rich color saturation, tactile softness, and sheen intensity can either convey premium quality or diminish the experience. This depends entirely on the silk’s treatment.

Impact on Product Quality and Durability

I know the dyeing method significantly influences the long-term durability and colorfastness of textile products. Factors like dye concentration, pH levels, temperature, dyeing time, and post-dyeing treatments are crucial. For example, reactive dyes form covalent bonds with cotton. This provides excellent wash fastness. Dispersed dyes for polyester offer superior resistance to washing and light. Conversely, cotton dyed with direct dyes relies on weaker van der Waals forces. This tends to have lower color fastness to washing and light. Wool and silk, when dyed with acid dyes, exhibit good color fastness. This is due to strong ionic bonds. However, polyester can sublimate under high temperatures. This causes color changes. Nylon can fade over time when exposed to light. Post-dyeing treatments like washing remove unfixed dye. This reduces bleeding. Steaming improves dye penetration and fixation. Fixatives further enhance color fastness. They prevent dye migration and degradation.

I also consider how the fabrics dyeing process impacts specific fiber types:

| Fiber Type | Dye Type | Dyeing Method Impact | Durability/Colorfastness under Conditions |

|---|---|---|---|

| Cotton (Natural) | Reactive Dyes | Forms covalent bond | Excellent wash fastness; susceptible to fading from sunlight/washing |

| Cotton (Natural) | Direct Dyes | Adheres via weaker van der Waals forces | Lower color fastness to washing and light |

| Wool/Silk (Natural) | Acid Dyes | Strong ionic bonds with protein fibers | Good color fastness to light and washing; sensitive to pH changes |

| Polyester (Synthetic) | Dispersed Dyes | High affinity for hydrophobic fibers | Excellent color fastness to washing and light; prone to sublimation at high temperatures |

| Nylon (Synthetic) | Acid Dyes | Similar to wool/silk | Good color fastness; sensitive to light, leading to fading |

| Acrylic (Synthetic) | Basic Dyes | Provides vibrant colors | Moderate color fastness to washing and light; sensitive to high temperatures |

I also observe key differences in quality and durability between yarn-dyed and piece-dyed fabrics:

| Feature | Yarn-Dyed Fabric | Piece-Dyed Fabric |

|---|---|---|

| Color Penetration | Deeper and more uniform color penetration into the fibers. | Color may not penetrate as deeply, especially in thicker fabrics or tightly woven areas. |

| Color Fastness | Generally superior color fastness, less prone to fading or bleeding. | Can be good, but sometimes less durable than yarn-dyed, especially with repeated washing or exposure to sunlight. |

| Fabric Hand/Feel | Often has a softer, more consistent hand due to the dyeing process occurring before weaving, which can make the yarns more pliable. | Can sometimes feel stiffer or have a slightly different texture due to the post-weaving dyeing process, which might affect the fabric’s drape. |

| Shrinkage | Generally more stable with less shrinkage, as yarns are pre-treated. | Can be more prone to shrinkage if not properly pre-shrunk during the dyeing process. |

| Durability | Often considered more durable in terms of color and pattern integrity over time. | Durability can vary; printed patterns might show wear more quickly than woven patterns. |

I believe choosing the right fabrics dyeing process is a strategic decision for brand success. I always match dyeing methods to design goals, budget, and production needs. This thoughtful approach ensures product integrity and market appeal. It helps brands create products that resonate with their customers and thrive in the market.

FAQ

What is the primary difference between yarn-dyed and piece-dyed fabrics?

I dye yarn-dyed fabrics before weaving them. Conversely, I dye piece-dyed fabrics after weaving the entire fabric roll. This is the key distinction.

Which dyeing method is best for creating intricate patterns?

I recommend yarn-dyed fabrics for intricate patterns. Weaving pre-dyed yarns allows me to create complex designs like plaids and stripes with superior visual depth.

Which dyeing method offers better cost efficiency for solid colors?

I find piece-dyed fabrics more cost-efficient for solid colors. This method streamlines production for large volumes. It helps me achieve a lower price per meter.

Post time: Jan-04-2026