I see Custom Heavyweight Polyester Rayon Spandex Fabric (TRSP) as the ultimate choice for durable uniforms and outerwear. It provides unparalleled strength, flexibility, and comfort. This comfortable polyester rayon spandex fabric excels in demanding environments. I consider it a luxury polyester viscose fabric. Its stretch poly viscose fabric quality is perfect for women’s suit fabric and women office wear fabric. This is an excellent polyester viscose fabric for suit.

Key Takeaways

- TRSP fabric is a strong material. It mixes polyester, rayon, and spandex. This blend makes it last long and feel comfortable.

- This fabric is good for many clothes. You can use it for suits, jackets, and uniforms. It keeps its shape and color well.

- TRSP fabric is easy to care for. Wash it in cold water and air dry. This helps your clothes stay nice for a long time.

The Unrivaled Blend: Why TRSP Fabric Excels in Durability and Comfort

Polyester: The Foundation of Lasting Strength

I find polyester forms the backbone of TRSP fabric. It gives the fabric its incredible strength. This strength makes it highly resistant to wear and tear. Polyester also resists stretching and shrinking. I see its tensile strength as very high, making it a durable choice. It also has excellent abrasion resistance. This means it stands up well to rubbing and friction. It does not pill easily. This makes garments last longer and look good. Polyester also resists most chemicals. It holds up well to UV light. This ensures the fabric maintains its integrity over time.

Rayon: Elevating Comfort and Breathability

I believe rayon elevates the comfort of TRSP fabric. It adds a soft feel and breathability. Rayon is highly breathable. It often surpasses synthetic fibers like polyester. It also wicks away moisture efficiently. I know it absorbs moisture well. But it dries faster than cotton. This gives a cooler feel, especially in humid conditions. I see rayon’s air permeability at 320 cm³/cm²/s. This is higher than cotton’s 260 cm³/cm²/s. This means more air flows through the fabric. This is good for damp weather. Rayon also absorbs moisture at 15-18%. This is less than cotton’s 24-27%. But its faster evaporation rate helps prevent garments from clinging.

Spandex: The Advantage of Dynamic Stretch and Recovery

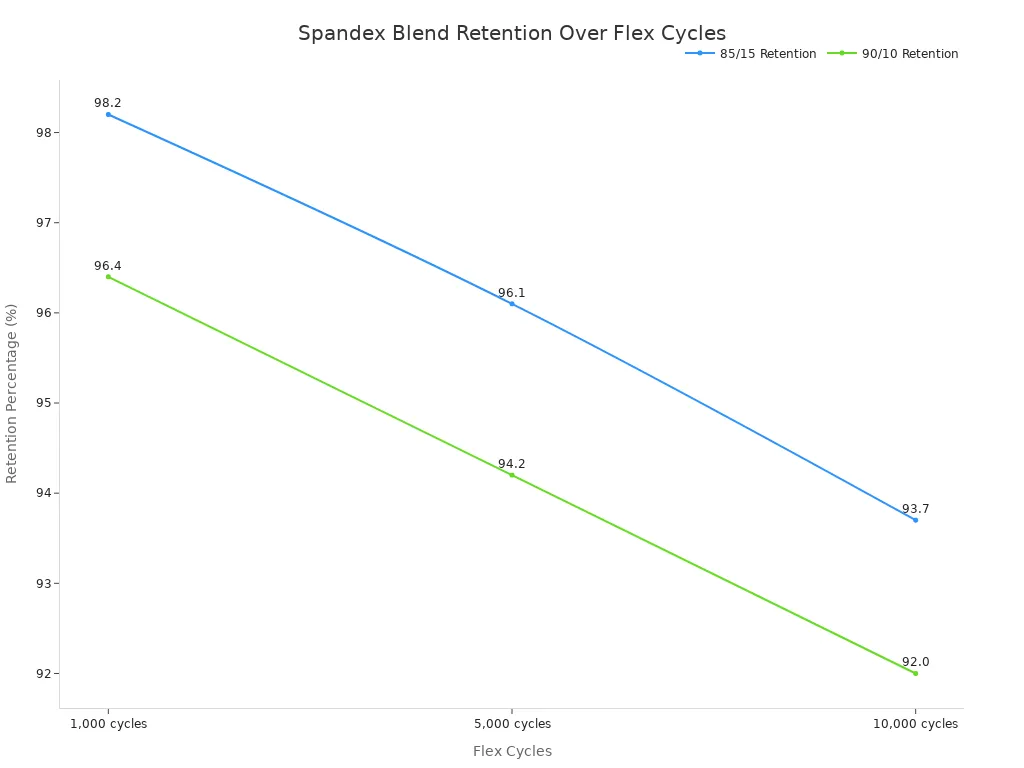

I think spandex gives TRSP fabric its dynamic stretch. It also provides excellent recovery. Spandex can stretch up to 500% to 600% of its original size. It then returns almost completely to its initial state. This recovery rate is usually 90% to 100%. This high elasticity ensures garments keep their shape. It provides a secure and comfortable fit. This is important for activewear and professional apparel. I see how this contributes to the longevity of the clothing. For example, a blend with 4% spandex shows strong retention. Even after 10,000 flex cycles, it retains over 92% of its original shape. This chart shows how well these blends hold up over time:

The 85/15 blend (likely 85% main fiber, 15% spandex) shows 93.7% retention after 10,000 cycles. The 90/10 blend (90% main fiber, 10% spandex) shows 92.0% retention. This proves the fabric’s ability to resist sagging and maintain its form.

Engineered for Excellence: 325GSM and 360GSM Options

I offer TRSP fabric in two substantial weights: 325GSM and 360GSM. GSM stands for grams per square meter. It tells me how dense the fabric is. Both options are heavyweight polyester rayon spandex blends. They share key performance characteristics. These include durability, wrinkle resistance, and excellent stretch recovery. I find these fabrics perfect for outerwear like jackets. They offer both structure and comfort. They have a smooth twill texture and a soft feel. The 360GSM option is slightly heavier. This gives me versatility for different seasonal collections. I believe these weights ensure the fabric is robust. It can withstand demanding environments. It also provides comfort for the wearer. This makes it an ideal polyester viscose fabric for suit and other structured apparel.

Performance Beyond Expectation: TRSP for Professional Wear and Outerwear

Superior Resistance to Wear, Tear, and Pilling

I know durability is paramount for professional wear. My TRSP fabric excels in this area. I see its superior resistance to wear, tear, and pilling. This is crucial for garments that face daily demands. My fabric undergoes rigorous testing. These tests confirm its robust nature.

I use various methods to assess durability:

- Pilling, Abrasion, and Snagging Tests:

- Smartindale

- Unidale

- Tumble Pilling

- Pilling and Snagging

- ICI Mace Snagging

- Strength Tests:

- Hydraulic Bursting Strength

- Pneumatic Bursting Strength

- Elmendorf Tear Strength Test

I also look at specific performance metrics. For example, my woven upholstery fabrics show excellent results:

| Property | Fabric Type | Test Method | Minimum Result |

|---|---|---|---|

| Pilling | Woven Upholstery | ASTM D3511 (Brush Pill) | Class 3 minimum |

| Pilling | Woven Upholstery | ASTM D4970 (Martindale) | Class 3 minimum |

| Abrasion | Woven Upholstery (Low Traffic) | Wyzenbeek (ASTM D4157) | 15,000 double rubs |

| Abrasion | Woven Upholstery (Low Traffic) | Martindale (ASTM D4966) | 20,000 cycles |

| Abrasion | Woven Upholstery (High Traffic) | Wyzenbeek (ASTM D4157) | 30,000 double rubs |

| Abrasion | Woven Upholstery (High Traffic) | Martindale (ASTM D4966) | 40,000 cycles |

| Abrasion | Coated Upholstery (High Traffic) | Wyzenbeek (ASTM D4157) | 50,000 double rubs |

| Tear Strength | Coated Upholstery (Knits & Woven Substrates) | ASTM D2261 (Tongue Tear) | 4 in x 4 lbs |

| Tear Strength | Coated Upholstery (Nonwoven Substrates & Composites) | ASTM D5733 (Trap Tear) | 15 in x 15 lbs |

These results demonstrate the fabric’s ability to withstand significant stress. I ensure my fabric maintains its smooth appearance. It resists the formation of unsightly pills. This means garments look new for longer.

Unwavering Colorfastness and Shape Retention

I understand colorfastness and shape retention are vital for professional apparel. My TRSP fabric delivers unwavering performance in these areas. I design it to maintain its original color and form. This ensures a consistently sharp appearance.

I rely on established industry standards to measure colorfastness:

- Colorfastness to Washing: AATCC TM61 (Colorfastness to Laundering: Accelerated)

- Colorfastness to Light: AATCC TM16.1 (Outdoor), AATCC TM16.2 (Carbon-Arc), AATCC TM16.3 (Xenon-Arc)

- Colorfastness to Rubbing (Crocking): AATCC TM8 (Crockmeter), AATCC TM116 (Rotary Vertical Crockmeter)

These tests are comprehensive. For example, AATCC 61 washing tests simulate multiple launderings. They use variations like 3A (71°C) and 4A/5A (chlorine-based bleach). Both EU and U.S. standards use stainless steel balls for abrasion. This ensures a thorough evaluation.

For light exposure, I use standards like ISO 105 B02 and AATCC 16. Both employ a Xenon Arc lamp. They assess color change using a blue wool reference scale or the Grey Scale. A grade 4 rating is typically accepted. This means the fabric resists fading from sunlight.

Rubbing tests, like ISO 105 X12 and AATCC 8, use a crockmeter. This device rubs test samples with dry and wet cloths. I assess staining using the Grey Scale for Staining. A grade 4 for dry rubbing and grade 3 for wet rubbing are commonly accepted. This confirms the fabric’s color will not transfer easily.

My fabric’s polyester component provides excellent shape retention. It resists stretching and shrinking. The spandex ensures dynamic stretch and recovery. This combination means garments keep their tailored silhouette. They do not sag or lose form, even after extended wear.

The Ideal Polyester Viscose Fabric for Suits and Structured Apparel

I find TRSP fabric is the ideal polyester viscose fabric for suit and other structured apparel. It combines the best qualities of its components. This creates a fabric with superior drape, wrinkle resistance, and hand feel.

For wrinkle resistance, my polyester viscose blends offer a “built-in memory” from polyester. This allows fabrics to return to shape. Viscose prevents deep creases. This combination ensures suit pants maintain crisp pleats. They avoid crumpling at natural bend points. Unlike wool, which requires steam ironing, these blends can self-straighten overnight when hung. This makes them ideal for travel. Industry insiders report that polyester viscose suits show approximately 80% less wrinkling after a full day compared to traditional wool mixtures. Financial analysts and lawyers note that lapels remain sharp. Consultants appreciate the absence of creases from prolonged sitting during flights. Around 85% of busy corporate workers confirm the fabric stays fresh throughout the day.

Regarding hand feel, the viscose component significantly enhances breathability and softness. It absorbs up to 50% more moisture than synthetic fibers. This effectively manages humidity while maintaining a soft touch. This breathability allows air circulation. It keeps areas like the collar and underarms cool. When combined with polyester’s stable structure, the material wicks sweat away without sticking to the skin. Research indicates that individuals wearing these fabrics experienced about 23% less tiredness during long meetings. This is due to better airflow and reduced body heating.

In terms of drape, my blend combines polyester’s stability with viscose’s natural flow. This ensures suits fall correctly without losing shape. These blended fabrics hold their form about 30% better than regular polyester. Research in Textile Tech Journal confirms this. This means crisp lines remain intact for business professionals. The material resists sagging at elbows and knees, unlike traditional wool. It maintains a tailored appearance all day. A 55/45 polyester-viscose ratio results in a silken luster comparable to premium wool. This specific blend improves drape quality by 22% over 100% polyester. Textile drape coefficient testing confirms this. It also maintains essential crease resistance for daily wear. The fabric, at 180 grams per square meter, achieves an optimal texture. It balances a wool-like softness (with 2.8 N friction resistance) with the tensile strength necessary for structured elements like lapels and seams. These qualities have led 68% of menswear brands to adopt polyester viscose blends for their entry-level luxury suits. The 2023 Textile World Report on formalwear material trends confirms this. My TRSP fabric is truly an excellent polyester viscose fabric for suit.

Effortless Care and Maintenance for Busy Professionals

I understand busy professionals need easy-care garments. My TRSP fabric offers effortless care and maintenance. This maximizes its lifespan and maintains its performance characteristics.

I recommend these simple care instructions:

- Hand or delicate machine wash with a low spin cycle.

- Use cold water only (colder than 85°F / 30°c).

- Wash with similar colors and materials.

- Do NOT dry clean, use bleach, or use fabric softeners.

- Air dry only; do NOT use a tumble dryer.

- Do not iron.

- Store out of direct sunlight.

I also advise caution with color bleeding. This is especially true with red and orange stripes, or dark/light combinations. New striped garments may release excess dye during initial washes. I recommend washing them separately for the first few cycles. Hot water significantly increases the risk of color bleeding. It has a 75% higher rate compared to cold water. I suggest using color-catching sheets in each wash cycle to trap loose dyes. Testing colorfastness on hidden seams before the first wash is also a good practice. Consistently washing items in cold water (below 30°C/86°F) preserves color integrity. Sorting laundry carefully by color intensity prevents dye transfer. For stain treatment, I apply solutions from the back of the fabric. I use a clean white cloth, dabbing gently without rubbing. Always test any stain removal product on an inside seam first. Soaking times vary by fabric. For synthetics like TRSP, I recommend cool water for 15 minutes.

These straightforward care steps ensure my TRSP fabric remains pristine. It continues to perform at its best. This makes it a practical choice for demanding professional environments.

Customization and Versatility: Tailoring TRSP to Your Brand’s Needs

Custom Weave and Finish Options for Unique Aesthetics

I know every brand wants a unique identity. My TRSP fabric offers extensive customization. You can choose specific weave patterns. This creates a distinct look and feel. I also provide various finish options. These finishes enhance the fabric’s aesthetics. They also improve its performance. For example, a brushed finish adds softness. A water-repellent finish protects against elements. These choices allow brands to create truly unique garments. I help you achieve your desired aesthetic.

Adapting TRSP for Diverse Uniform and Outerwear Applications

I see TRSP fabric as incredibly versatile. It adapts well to many uniform and outerwear needs. I design it for women’s suits and jackets. It also works for trousers and winter skirts. Bomber jackets also benefit from its properties. Its blend of strength and flexibility makes it ideal. This fabric performs in various professional settings. It provides comfort and durability. I ensure it meets the demands of diverse applications.

Accelerated Production with In-Stock Greige Fabric

I understand the need for quick production. My in-stock greige fabric helps accelerate your process. Greige fabric is undyed. This allows for custom dyeing with a short lead time. This significantly speeds up your production.

For textiles that are printed to order, the current lead time is approximately 3-4 weeks.

When utilizing in-stock greige fabric, custom dyeing can be completed with a short lead time, which helps brands accelerate their production process.

I offer this efficiency to my clients. It means you get your custom fabrics faster. This helps you bring your designs to market quickly.

I believe investing in custom heavyweight TRSP stretch fabric is a smart choice. It ensures uniforms and outerwear deliver exceptional durability, comfort, and performance. This provides long-term value and wearer satisfaction. This premium fabric, an ideal polyester viscose fabric for suit, goes beyond basic. It sets a new standard for quality and functionality in professional apparel.

FAQ

What makes TRSP fabric exceptionally durable?

I find TRSP fabric durable due to its blend. Polyester provides strength and resists wear. Spandex adds stretch and shape retention. Rayon enhances comfort and breathability.

Can I use TRSP fabric for various clothing types?

Yes, I design TRSP fabric for versatility. It works well for women’s suits, jackets, trousers, and winter skirts. It is also perfect for bomber jackets.

How do I care for garments made with TRSP fabric?

I recommend hand or delicate machine washing in cold water. Air dry only. Avoid dry cleaning, bleach, fabric softeners, and tumble drying.

Post time: Nov-11-2025