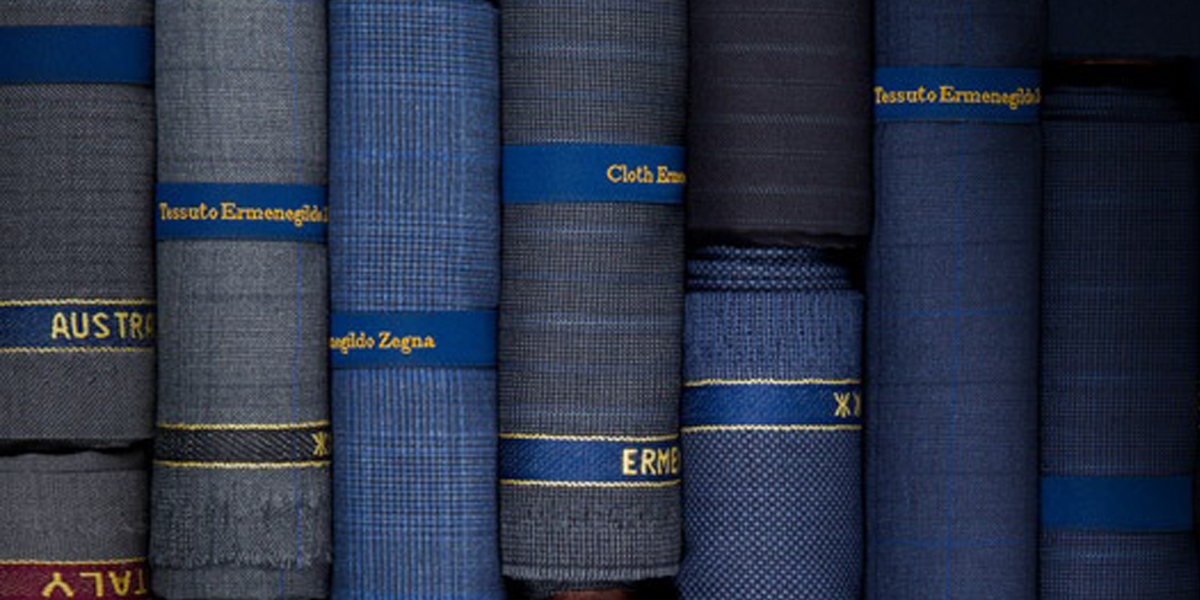

Not all fabrics age equally. I know a fabric’s inherent structure dictates its long-term appearance. This understanding empowers me to choose lasting styles. For instance, 60% of consumers prioritize durability for denim, impacting fabric appearance retention. I value a polyester rayon blended fabric structure for long wear fabric. This ensures TR uniform fabric appearance retention and good suit fabric appearance retention, often through uniform fabric weave technology.

Key Takeaways

- Fabric structure affects how clothes look over time. Woven fabrics are strong. Knitted fabrics are flexible. Non-woven fabrics are economical.

- A fabric’s density and texture change how long it lasts. Tightly woven fabrics resist wear. Smooth fabrics resist small balls forming on the surface.

- Good care helps fabrics last longer. Following washing and drying instructions keeps clothes looking new. This protects your investment.

Understanding Fabric Structures

When I evaluate fabrics, I know their fundamental structure tells me a lot about their future. Different construction methods give fabrics unique properties. This directly impacts how they look and perform over time.

Woven Fabrics: Interlaced Strength

I recognize woven fabrics by their distinct interlaced pattern. Here, warp threads run lengthwise, and weft threads cross them at right angles. This creates a strong, stable material. I see how the yarn count, interlacing order, and thread density all influence the final structure. For example, simple woven structures use one series of warp and weft threads. This over-under pattern gives woven fabrics resistance to diagonal stretch. I also notice that when I cut woven fabrics, they tend to fray at the edges. This stability and firmness set them apart.

Knitted Fabrics: Looped Flexibility

Knitted fabrics offer a different experience; I appreciate their inherent flexibility. Their structure comes from inter-meshed loops. This gives them high elasticity, especially along the vertical axis, making them incredibly soft and comfortable. I find knitted fabrics more resilient than other structures; they bend without distortion. Their porosity also allows gas or liquid to pass through easily. I know two main types exist: weft knitting, where yarns flow horizontally, and warp knitting, where yarns follow a more vertical path. Warp knits, in particular, resist fraying.

Non-Woven Fabrics: Bonded Simplicity

Non-woven fabrics represent a fascinating category. I see their production as incredibly fast and efficient, moving from raw material to finished fabric in one continuous process. This makes them very economical, especially for single-use items. I also value the customization options non-wovens offer. Manufacturers can select various fibers and bonding methods to achieve specific properties. Their look and feel differ significantly from woven fabrics; they can feel paper-like, felt-like, or even have a uniform, plastic-like texture. While they might not always match the tensile strength of heavy wovens, I find non-wovens often excel in permeability and stretch.

Structure’s Impact on Durability and Wear

I know a fabric’s structure directly influences how well it withstands daily use. This impacts its durability and how it shows wear over time. Understanding these factors helps me choose fabrics that maintain their appearance.

Weave Density and Abrasion Resistance

I find weave density crucial for a fabric’s ability to resist abrasion. Abrasion happens when friction, rubbing, or chafing wears down a fabric. Fabrics with a tighter construction and higher yarn counts offer superior protection against this friction. I see how the density of both warp and weft yarns, along with the specific weave pattern, affects this. Weaves with more interlacing points per unit length enhance fiber attachment to the yarn. This happens even when the thread count per unit length is the same.

In my experience, smooth, flat woven fabrics generally exhibit better abrasion resistance than textured knits. Woven types like twill and plain weaves tend to outperform satin or other weaves with wider yarn spacing. Loose weaves and knits allow more yarn-on-yarn movement. This makes them less resistant to abrasion.

I also know that industry standards exist to measure abrasion resistance. These tests help me understand a fabric’s potential longevity. Common methods include:

- Martindale test method: This test is widely used for various textile types. It assesses abrasion resistance and appearance changes. Key indicators are the number of cycles a fabric can endure.

- Taber Abrasion test: I use this test for floor coverings and coated textiles. It focuses on the amount of abrasion.

Several international and national standards guide these tests:

- ISO12947.3-1998: This standard focuses on determining quality loss in textiles using the Martindale method.

- ASTMD4966-2010: This is an American standard for the Martindale Abrasion Tester.

- ASTM D3885-07a(2024): This standard test method determines the abrasion resistance of woven or nonwoven textile fabrics using a flexing and abrasion tester. I find this method applicable to most woven and nonwoven fabrics that do not stretch excessively.

Surface Texture and Pilling Resistance

I observe how a fabric’s surface texture plays a significant role in its resistance to pilling. Pilling occurs when short or broken fibers on the fabric surface tangle together. They form small balls or “pills.” I prefer fabrics that naturally resist this.

Certain fabric textures exhibit high resistance to pilling:

- Smooth Fabrics: These fabrics are less prone to pilling. Their fibers do not lift or tangle easily. This helps them maintain their appearance over time.

- Chenille and Velvet: These materials have plush surfaces. This reduces pilling by preventing fibers from lifting and tangling. They maintain a smoother look for longer.

- Linen: I value linen for its long and sturdy fibers. It exhibits better pilling resistance and is less prone to tangling.

- Silk: Silk fibers are naturally smooth and strong. This prevents them from breaking and forming pills. It contributes to better pilling resistance.

- Rayon: As a semi-synthetic fiber, rayon has a slicker texture. This helps deter pilling. However, it can pill with rough washing or frequent friction.

Snagging Susceptibility

I understand that some fabric structures are more prone to snagging. Snagging happens when a fabric catches on a sharp object. This pulls loops or yarns out of the fabric surface. It creates an unsightly defect. I have identified specific fabric structures that show poor snag resistance:

- Terry loop knit (fabric #8): This fabric exhibited poor snag resistance. It often received worst grades of 1–2 in testing.

- 1×1 rib knit (fabric #5): I found this knit also showed poor snag resistance. It often received worst grades of 3.

- A decorative woven fabric (fabric #12): This fabric had a worst-grade rating of 1–2 in the warp direction. This indicates poor snag resistance.

- A mesh fabric (fabric #9): This fabric achieved a worst-grade rating of 2–3 in the weft direction. This also indicates poor snag resistance.

I always consider these structural weaknesses when selecting fabrics for specific uses. This helps me avoid future disappointment.

Maintaining Shape and Form for Fabric Appearance Retention

I know a fabric’s ability to hold its original shape is crucial for its long-term aesthetic. This directly impacts fabric appearance retention. When fabrics lose their form, they look worn and old, even if the fibers themselves are intact.

Shape Retention and Stability

I prioritize fabrics that maintain their shape. This stability prevents stretching, sagging, or distorting over time. Manufacturers use several techniques to enhance a fabric’s shape retention:

- They select the correct yarn count or denier to achieve a specific GSM (Grams per square meter).

- They implement appropriate loop or weave density/tightness factor (loop length).

- They apply chemical treatments like mercerizing for cotton or resination for woven cotton materials.

- They utilize heat setting, pre-heat-setting, and post-heat setting for synthetic and blended fabrics. This thermal process imparts dimensional stability.

- Finishing processes on machines like sanforizing or compacting mechanically shrink the fabric. This minimizes residual shrinkage after laundering.

- They pre-shrink fabrics in the factory to prevent later shrinkage issues.

- They apply the London shrunk process to specific woolen materials. This enhances dimensional stability and shrinkage resistance.

Wrinkle Resistance and Recovery

I value fabrics that resist wrinkles and recover quickly from creasing. This significantly contributes to good fabric appearance retention. Different fabric structures influence these properties. Lofty knits, high-twist yarns, and stretch blends enhance mechanical recoil. This helps flatten minor creases. Dense weaves, such as gabardine, are effective at concealing wrinkles. Loose, open constructions, however, allow folds to set more easily.

I find that solid structures, with their higher density and more interlacing points, provide better crease recovery. This is due to greater elastic recovery force. In contrast, semi-transparent structures, having lower density and fewer interlacing points, exhibit weaker crease recovery. Their effect can be complex and dependent on proportion. Mesh structures, characterized by high porosity and minimal interlacing points, deform easily and have difficulty recovering. They do offer benefits like air permeability. The proportion of solid structure within a fabric blend significantly influences overall crease recovery. A higher proportion generally leads to improved recovery properties.

Drape and Hand Over Time

I understand that a fabric’s drape and hand define its aesthetic flow and feel. Drape refers to how a fabric hangs or falls. Hand describes its tactile qualities. A fabric’s structure dictates these characteristics. Over time, structural changes can alter them. A well-constructed fabric maintains its intended drape and hand, contributing to its lasting appeal. Poorly constructed fabrics might stiffen, soften excessively, or lose their original flow.

Color and Aesthetic Longevity

I know a fabric’s structure significantly influences how its color appears and endures. This is a critical aspect of long-term aesthetic appeal.

How Structure Affects Color Appearance

I observe how a fabric’s structure directly impacts its color. The fiber composition and weave structure influence a fabric’s ability to absorb and retain dye. This affects the final color appearance. For example, linen’s unique texture contributes to the depth of colors. This makes them appear richer. Silk’s natural protein structure allows it to absorb and reflect colors with notable depth and luster. This results in vibrant and brilliant hues.

I also see how advanced materials enhance color. The incorporation of black materials like MXene and polydopamine (PDA) can significantly enhance the vibrancy and saturation of structural colors. They absorb scattered light. This improves visual contrast and richness. The arrangement of black MXene layers specifically diminishes coherent light scattering. It minimizes reflection. This leads to more vibrant structural colors. I also understand that the size of microspheres, like MSiO2/PDA@MXene, directly influences the resulting hues. This allows for the generation of diverse structural colors.

Fading and Environmental Exposure

I recognize that a fabric’s structure also plays a role in its resistance to fading. Environmental factors like sunlight and washing can degrade dyes. A tightly woven fabric often offers more protection to its fibers and dyes. This reduces direct exposure to UV radiation. Looser weaves or knits might allow more light penetration. This can accelerate fading. The way fibers are structured and how tightly they hold the dye molecules also impacts color fastness. I always consider these structural elements when evaluating a fabric’s potential for long-term color retention.

Choosing Fabrics for Lasting Style

I know choosing the right fabric is key for long-lasting style. This means I consider how the fabric’s structure will perform over time. I always think about the intended use and how I will care for the item.

Matching Structure to Use

I always match a fabric’s structure to its intended use. This ensures the item performs well and maintains its look. For high-wear applications, I look for structures designed for durability. For example, industrial fabric structures need to withstand harsh conditions.

I have learned that certain materials offer superior protection against wear:

- High-density polyethylene (HDPE) fabric provides increased protection. It has a high strength-to-density ratio.

- PVC can help a structure withstand damage from severe weather and heavy use.

- Hot-dip galvanized (HDG) steel reinforces frameworks. It boosts their ability to weather corrosion and rust. This material can last for generations.

I know industrial fabric structures are guaranteed to have a long lifespan. They last 15 to 25 years when made with durable fabric. Steel-framed fabric structures can last 15 to 40 years. This shows their suitability for long-term, high-wear applications. I choose a tightly woven denim for jeans. I pick a soft knit for a comfortable sweater. This careful selection helps me achieve lasting satisfaction.

The Importance of Fabric Density

I understand fabric density directly impacts a textile product’s longevity. It influences strength, durability, and resistance to wear. Higher fabric density means the yarns are more closely interwoven. This creates a stronger, more durable material. It also increases resistance to wind, abrasion, and wrinkles.

Conversely, less dense fabrics have a looser construction. This leads to easier wear and reduced durability. This relationship is very clear in woven textiles. Higher fabric density, measured by EPI (ends per inch) x PPI (picks per inch), is a significant factor. It determines fabric strength and overall performance.

I use this table to guide my choices:

| Parameter Combination | Durability |

|---|---|

| High Count, High Density | High |

| Low Count, High Density | Very High |

| High Count, Low Density | Low |

| Low Count, Low Density | Low |

I always aim for high density when durability is a priority.

Fiber Type and Structural Synergy

I know fiber type and fabric structure work together. This synergy greatly influences a fabric’s long-term appearance. A strong fiber in a weak structure will not perform well. A weak fiber in a strong structure also has limitations. For example, I find natural fibers like cotton or linen in a plain weave offer breathability and comfort. However, they might wrinkle more easily than synthetics. Polyester fibers, known for their strength and wrinkle resistance, perform exceptionally well in a tight twill weave. This combination creates a very durable and low-maintenance fabric. I always consider how the fiber’s inherent properties complement the fabric’s construction. This helps me predict how the material will age.

Care Instructions and Longevity

I always follow care instructions. This maximizes a fabric’s structural integrity and appearance. Proper care extends the life of my garments and textiles.

Here are my smart washing tips:

- I always check care labels. This prevents damage and prolongs fabric life.

- I use gentle detergents. I choose mild, liquid detergents for delicate fabrics. This avoids harshness and residue.

- I use cold water settings. Washing in cold water prevents fiber shrinkage and color fading. This preserves material integrity.

- I set my machine to delicate. This is gentler on fabric. It prevents stretching or tearing.

- I avoid overloading the machine. This allows fabric to move freely. It ensures thorough cleaning and prevents wrinkles.

I also have clever drying tips:

- I tumble dry on low heat if permitted. This avoids damaging delicate fibers and shrinkage.

- I remove items promptly. I take out bedding while slightly damp. This avoids wrinkles and maintains shape.

- I air dry when possible. This is the gentlest method. I hang items flat in a well-ventilated area away from direct sunlight.

- I smooth by hand. I gently smooth out wrinkles after drying. This enhances appearance.

For stain removal, I follow these tips:

- I act fast. Fresh stains are easier to remove.

- I blot, I do not rub. I gently blot with a clean, white cloth. This avoids pushing the stain deeper or damaging fibers.

- I use cold water first. I rinse with cold water as a first step. Hot water can set stains.

- I choose gentle stain removers. I use mild products designed for delicate fabrics. I avoid bleach or harsh chemicals.

- I test first. I always test cleaning solutions on a hidden area.

- I use natural alternatives for lighter stains. I use a baking soda paste or diluted white vinegar.

- I rinse thoroughly. After treating, I rinse with cold water. This removes all cleaning agents.

- I air dry first. I avoid using a dryer until the stain is completely gone. Heat can set it permanently.

Proper care offers many benefits. It contributes to structural integrity and fabric appearance retention:

- It enhances comfort and sleep quality. Regular care keeps fabrics soft, cozy, and inviting. It eliminates allergens, odors, and dust mites.

- It extends the lifespan of my bedding. Specialized care prevents damage like fraying, thinning, or pilling. This allows high-end materials to last longer.

- It maintains aesthetic appeal. Gentle care prevents fading. It preserves vibrant colors and elegant designs. This keeps fabrics looking polished and luxurious.

- It improves health and hygiene. Regular maintenance removes allergens. This contributes to a healthier environment.

- It maximizes my investment. Caring for fabrics protects their quality and value. This ensures long-term enjoyment.

Seasonal maintenance and proper storage are also crucial for maximizing longevity and appearance:

- I rotate bedding for the seasons.

- I switch to appropriate weight fabrics. For example, I use linen for warm months and flannel for cold. This prevents unnecessary wear.

- I deep clean and thoroughly dry seasonal bedding before storing. This prevents discoloration or mildew.

- I store properly in breathable cotton bags or boxes. I avoid plastic bins that trap moisture.

- I refresh each season.

- I air out linens outdoors on a sunny day. This removes odors.

- I invest in professional cleaning at least once per season. This provides thorough cleaning of delicate items.

- I inspect for wear and tear. I look for loose threads or holes. This helps me address issues early.

- I store between uses.

- I fold loosely. This avoids creases that weaken fibers.

- I include freshening agents like lavender or cedar. This repels pests.

- I store in a cool, dark, and dry place. This protects materials from fading or mold.

I find understanding fabric structure fundamental. It helps me make informed choices for garments and textiles. A fabric’s long-term aesthetic comes from its inherent structural integrity. I always consider fabric structure when purchasing. This ensures lasting satisfaction and excellent fabric appearance retention.

FAQ

What is the main difference between woven and knitted fabrics?

I know woven fabrics interlace threads. This creates a strong, stable structure. Knitted fabrics loop threads. This gives them flexibility and stretch.

How does fabric density affect durability?

I find higher fabric density increases durability. It makes the material stronger. It resists wear and abrasion better.

Why is proper care important for fabric longevity?

I believe proper care extends fabric life. It maintains appearance. It preserves structural integrity. This maximizes my investment.

Post time: Jan-05-2026