When choosing a swimsuit, in addition to looking at the style and color, you also need to look at whether it is comfortable to wear and whether it hinders movement. What kind of fabric is the best for a swimsuit? We can choose from the following aspects.

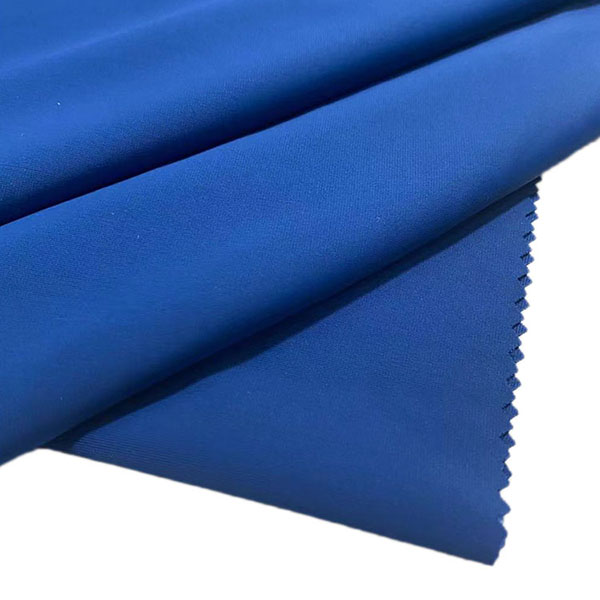

First, look at the fabric.

There are two common swimsuit fabric combinations, one is "nylon + spandex" and the other is "polyester (polyester fiber) + spandex". The swimsuit fabric made of nylon fiber and spandex fiber has high wear resistance, elasticity and softness comparable to Lycra, can withstand tens of thousands of times of bending without breaking, easy to wash and dry, and is currently the most commonly used swimsuit fabric. The swimsuit fabric made of polyester fiber and spandex fiber has limited elasticity, so it is mostly used to make swimming trunks or women's swimsuits, and is not suitable for one-piece styles. The advantages are low cost, good wrinkle resistance and durability.Formality.

Spandex fiber has excellent elasticity and can be freely stretched to 4-7 times its original length. After releasing the external force, it can quickly return to its original length with excellent stretchability; it is suitable for blending with various fibers to enhance the texture and drape and wrinkle resistance. Usually, the content of spandex is an important criterion for judging the quality of swimsuits. The spandex content in high-quality swimsuit fabrics should reach about 18% to 20%.

Swimsuit fabrics loosen and become thinner after being worn many times are caused by spandex fibers being exposed to ultraviolet rays for a long time and stored under high humidity. In addition, in order to ensure the sterilization effect of swimming pool water, the swimming pool water must meet the standard of residual chlorine concentration. Chlorine can linger on swimwear and accelerate the deterioration of spandex fibers. Therefore, many professional swimsuits use spandex fibers with high chlorine resistance.

Second, look at the color fastness.

Studies have shown that sunlight, swimming pool water (chlorine-containing), sweat, and sea water can all cause swimsuits to fade. Therefore, many swimsuits need to look at an indicator during quality inspection: color fastness. The water resistance, sweat resistance, friction resistance and other color fastness of a qualified swimsuit must reach at least level 3. If it does not meet the standard, it is best not to buy it.

Three, look at the certificate.

Swimsuit fabrics are textiles that are in close contact with the skin.

From fiber raw materials to finished products, it needs to go through a very complicated process. If in the production process, the use of chemicals in some links is not standardized, it will lead to the residue of harmful substances and threaten the health of consumers. The swimsuit with the OEKO-TEX® STANDARD 100 label means that the product is compliant, healthy, environmentally friendly, free of harmful chemical residues, and follows a strict quality management system during the production process.

OEKO-TEX® STANDARD 100 is one of the world-renowned textile labels for testing harmful substances, and it is also one of the internationally recognized and widely influential ecological textile certifications. This certification covers the detection of more than 500 harmful chemical substances, including substances prohibited and regulated by law, substances harmful to human health, and biologically active and flame-retardant substances. Only manufacturers who provide quality and safety certificates in accordance with strict testing and inspection procedures are allowed to use OEKO-TEX® labels on their products.

Post time: Aug-16-2023