I often see confusion about selvedge suit fabric. All woven fabrics, like TR selvedge fabric or worst wool selvedge fabric, have a selvedge. Knit fabrics do not. The selvedge is a strong edge that keeps suit selvedge fabric from fraying. I trust selvedge fabric for suit making because it shows quality.

Key Takeaways

- Selvedge suit fabric has a strong, self-finished edge that prevents fraying and shows high craftsmanship.

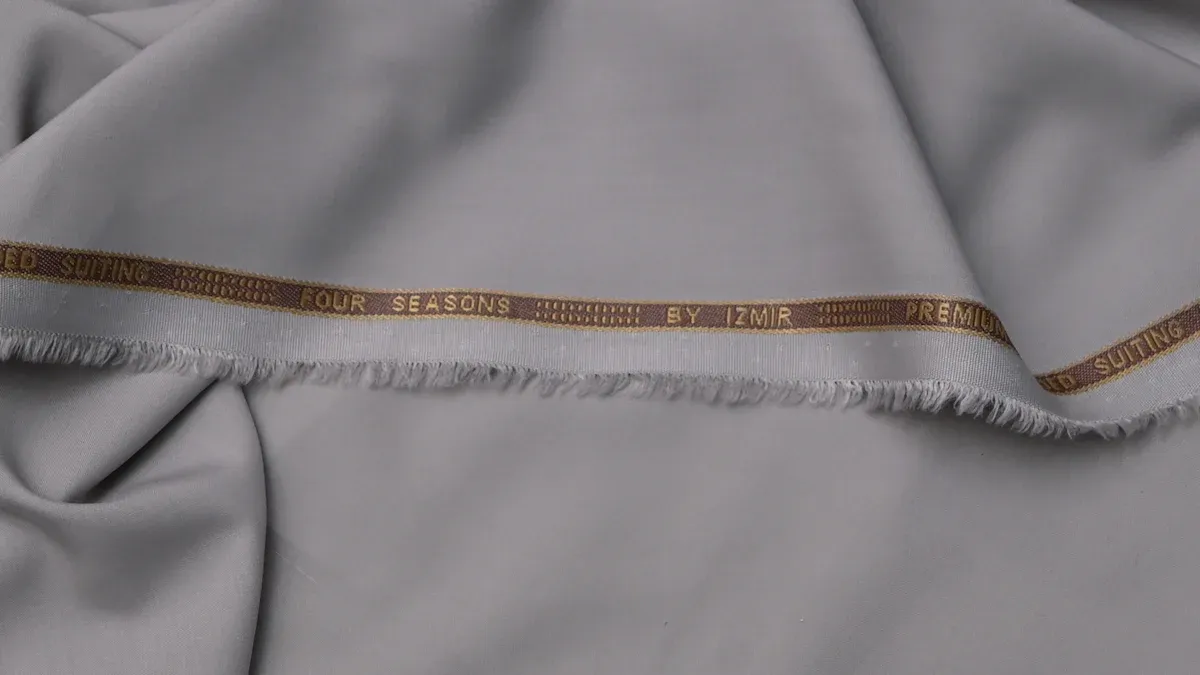

- You can identify selvedge fabric by its tight edge, less stretch along the grain, and often mill markings on the edge.

- Selvedge fabric costs more but lasts longer, keeps its shape, and needs careful washing and skilled tailoring.

Understanding Selvedge Suit Fabric

What Is Selvedge in Suit Fabric

When I work with selvedge suit fabric, I notice the difference right away. Selvedge, which means “self-edge,” describes the tightly woven edge of the fabric. This edge forms during weaving when the weft threads loop back at the end of each row. The result is a clean, finished boundary that resists fraying and holds the fabric together. In luxury tailoring, selvedge stands out as a mark of craftsmanship and quality. Mills use traditional shuttle looms to create this edge, producing fabric in smaller batches with great attention to detail. I value selvedge suit fabric because it reflects classic manufacturing techniques and superior durability. The weaving process requires skill and patience, making each piece unique and exclusive.

Selvedge suit fabric represents the highest standards in tailoring. The self-finished edge shows the care and tradition behind every yard.

How to Identify Selvedge Suit Fabric

I always check for selvedge when selecting fabric for a suit. Tailors use several methods to identify selvedge suit fabric:

- I inspect the edge of the fabric. The selvedge runs parallel to the lengthwise grain and looks tighter and cleaner than the rest of the fabric.

- I perform a stretch test by pulling the fabric diagonally. The bias stretches more, while the straight grain, which aligns with the selvedge, stretches less.

- I pull the fabric horizontally to find the direction with less stretch, confirming the straight grain.

- I make a small snip and tear the fabric. If it tears in a straight line, it follows the grain and likely includes the selvedge.

- I look for any print or weave patterns that help me spot the grain direction.

Manufacturers often add their mill name and location to the selvedge edge. This detail helps me confirm the fabric’s authenticity. I also rely on trusted recommendations and physical tests, such as a burn test, to avoid counterfeit materials.

Tip: Always check the edge for a tightly woven strip and any mill markings. These signs point to genuine selvedge suit fabric.

Selvedge vs. Non-Selvedge Suit Fabric

I compare selvedge suit fabric and non-selvedge fabric by looking at their structure and production methods. Selvedge fabric has a self-finished edge woven tightly as part of the fabric. This edge prevents fraying and gives the fabric a strong frame. Non-selvedge fabric lacks this edge and needs extra stitching to keep it from unraveling.

Here is a table that highlights the main differences:

| Feature | Selvedge Fabric | Non-Selvedge Fabric |

|---|---|---|

| Loom Type | Traditional shuttle looms (slower, older) | Modern projectile looms (faster) |

| Weft Yarn Insertion | Continuous, loops back at edge | Individual, cut at edges |

| Edge Finish | Self-finished, tightly woven | Cut edges, need extra finishing |

| Fabric Width | Narrower (28-36 inches) | Wider (58-60+ inches) |

| Production Speed | Slower | Faster |

| Edge Strength | Very strong, durable | Depends on finishing |

| Cost | Higher due to skill and time | Lower due to efficiency |

Selvedge suit fabric feels crisp and clean at the edges. It resists curling and damage better than non-selvedge fabric. The weaving process on shuttle looms takes more time and skill, which increases the cost but also the quality. Non-selvedge fabric, made on modern looms, offers wider rolls and faster production but sacrifices edge durability.

Note: I choose selvedge suit fabric for its strength, neatness, and lasting value. The extra care in production makes it worth the investment.

Why Selvedge Suit Fabric Matters

Quality and Durability of Selvedge Suit Fabric

When I choose fabric for a suit, I always look for quality and durability. Selvedge suit fabric stands out because of its strong, self-finished edge. This edge keeps the fabric from fraying, even after years of wear. I notice that suits made from selvedge fabric hold their shape better. The fabric feels dense and smooth, which gives the suit a crisp look. Mills use shuttle looms to weave selvedge fabric, and this process creates a tighter weave. The result is a fabric that resists stretching and tearing.

I have seen many suits lose their sharp lines after a few months. Selvedge suit fabric keeps its structure much longer. The edges do not curl or unravel. This makes the suit look new, even after many wears. I trust selvedge fabric for important events and daily business because it lasts. The extra strength in the weave means I do not worry about damage from regular use.

A suit made from selvedge fabric often becomes a favorite. It ages well and develops character over time.

Practical Considerations: Cost, Care, and Tailoring

When I recommend selvedge suit fabric, I always talk about cost, care, and tailoring. Selvedge fabric costs more than non-selvedge options. The weaving process takes more time and skill. Mills produce less fabric per hour, so prices go up. I believe the extra cost pays off in the long run. The suit lasts longer and looks better.

Caring for selvedge suit fabric requires attention. I follow these steps to keep my suits in top shape:

- I check if the fabric is sanforized or unsanforized to know how much it might shrink.

- I soak the suit inside out in warm water for 15-20 minutes to remove dirt and starch.

- I spot clean stains instead of washing the whole suit.

- I wash by hand with a gentle detergent like Woolite Dark to protect the color and texture.

- I rinse with cold water and hang the suit to air dry.

- I only wash the suit when needed to help it last longer.

I avoid hot water and harsh detergents. These can damage the fabric and fade the color. I also turn the suit inside out before washing to protect the surface. Air drying helps prevent shrinkage and keeps the fabric strong.

Tailoring selvedge suit fabric takes skill. The fabric is narrower, so tailors must plan carefully. I work with experienced tailors who know how to use every inch of the fabric. They often show off the selvedge edge inside the suit as a mark of quality. This detail adds value and shows the suit was made with care.

Tip: Choose a tailor who understands selvedge fabric. Good tailoring brings out the best in this special material.

I always look for quality and durability in suit fabrics. Selvedge fabric stands out for its clean, self-finished edge and strong construction.

- Selvedge fabric costs more but offers higher craftsmanship and durability.

- Non-selvedge fabric can be more affordable and still meets many needs.

- I weigh durability, cost, and style before making my choice.

FAQ

How do I store selvedge suit fabric?

I roll the fabric on a tube. I keep it in a cool, dry place. This method prevents wrinkles and protects the selvedge edge.

Tip: Avoid folding to prevent creases.

Can I use selvedge fabric for casual suits?

Yes, I often use selvedge fabric for both formal and casual suits. The fabric’s strength and clean edge work well for many styles.

Does selvedge fabric shrink after washing?

I notice some shrinkage, especially with unsanforized fabric. I always check with the mill or pre-wash the fabric to control the final fit.

Post time: Aug-14-2025