What do you know about the functions of textiles? Let's take a look!

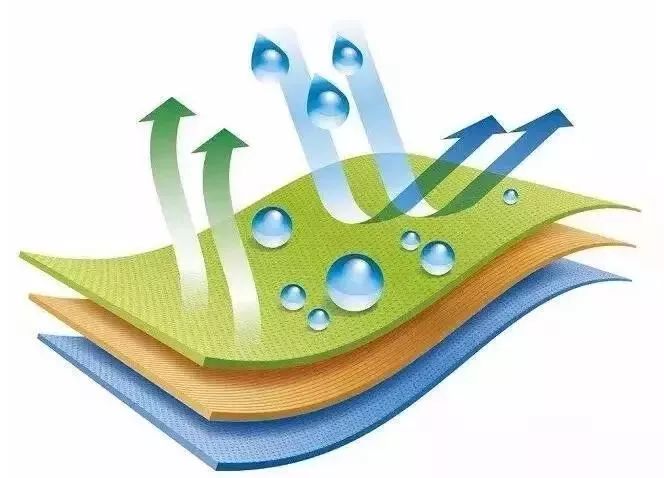

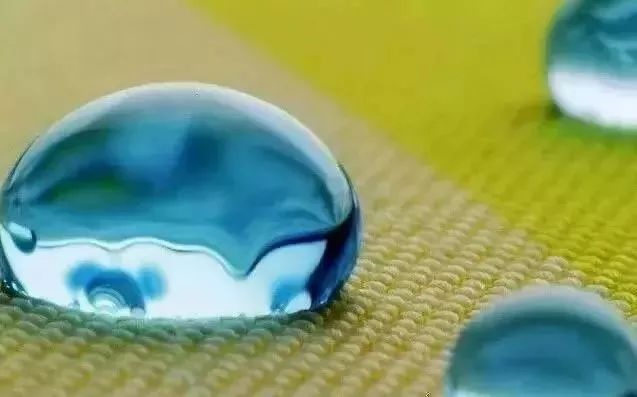

1.Water repellent finish

Concept: Water-repellent finishing, also known as air-permeable waterproof finishing, is a process in which chemical water-repellent agents are used to reduce the surface tension of fibers so that water droplets cannot wet the surface.

Application: Waterproof materials such as raincoats and travel bags.

Function: easy to handle, low price, good durability, and the fabric after water-repellent treatment can still maintain its breathability. The water-repellent finishing effect of the fabric is related to the structure of the fabric. It is mainly used for cotton and linen fabrics, and can also be used for silk and synthetic fabrics.

2.Oil repellent finishing

Concept: Oil-repellent finishing, the process of treating fabrics with oil-repellent finishing agents to form an oil-repellent surface on fibers.

Application: high-grade raincoat, special clothing material.

Function: After finishing, the surface tension of the fabric is lower than that of various oils, making the oil beaded on the fabric and difficult to penetrate into the fabric, thus producing an oil-repellent effect. The fabric after oil-repellent finishing is both water-repellent and Good breathability.

3.Anti-static finishing

Concept: Anti-static finishing is the process of applying chemicals to the surface of fibers to increase the hydrophilicity of the surface to prevent static electricity from accumulating on the fibers.

Causes of static electricity: Fibers, yarns or fabrics are generated due to friction during processing or use.

Function: Improve the hygroscopicity of the fiber surface, reduce the surface specific resistance, and reduce the static electricity of the fabric.

4.Easy decontamination finishing

Concept: Easy decontamination finishing is a process that makes the dirt on the surface of the fabric easy to remove by general washing methods, and prevents the washed dirt from re-contaminating during the washing process.

Causes of dirt formation: During the wearing process, fabrics form dirt due to the adsorption of dust and human excrement in the air and contamination. Generally, the surface of the fabric has poor hydrophilicity and good lipophilicity. When washing, water is not easy to penetrate into the gap between fibers. After being washed, the dirt suspended in the washing liquid is easy to re-contaminate the surface of the fiber, causing re-contamination.

Function: reduce the surface tension between fiber and water, increase the hydrophilicity of the fiber surface, and make the fabric easier to clean.

5.Flame retardant finishing

Concept: After being treated with certain chemicals, textiles are not easy to burn in case of fire, or extinguish as soon as they are ignited. This treatment process is called flame-retardant finishing, also known as fire-proof finishing.

Principle: The flame retardant decomposes to produce incombustible gas, thereby diluting the flammable gas and playing the role of shielding the air or inhibiting flame combustion. The flame retardant or its decomposition product is melted and covered on the fiber net to play a shielding role, making the fiber difficult to burn or preventing the carbonized fiber from continuing to oxidize.

We are specialized in functional fabric,if you want to learn more,welcome to contact us!

Post time: Dec-23-2022