Understanding colorfastness is critical for textile quality, especially when sourcing from a durable fabric supplier. Poor colorfastness can lead to fading and staining, which frustrates consumers. This dissatisfaction often results in higher return rates and complaints. Dry and wet rubbing fabric tests serve as essential methods to assess colorfastness, ensuring that fabrics, such as medical uniform fabric or TR fabric for workwear, meet high standards. By partnering with a supplier that offers high colorfastness fabric and custom textile solutions, businesses can enhance their product offerings and customer satisfaction.

Key Takeaways

- Dry and wet rubbing tests are essential for assessing fabric colorfastness and durability, helping to prevent color bleeding.

- Understanding test results allows buyers to make informed decisions, ensuring they select high-quality fabrics that meet durability standards.

- Conducting these tests regularly supports brand reputation and compliance with global quality standards, enhancing customer satisfaction.

What is a Fabric Test?

Fabric tests are essential evaluations that help determine the quality and durability of textiles. Among these tests, the dry and wet rubbing tests stand out as crucial methods for assessing colorfastness. Understanding these tests can significantly impact the quality assurance process in the textile industry.

Definition of Dry Rubbing Test

The dry rubbing test evaluates how well a fabric can withstand abrasion without losing its color. This test simulates the wear and tear that fabrics experience in everyday use. I often refer to two popular methods for conducting this test: the Wyzenbeek and Martindale tests.

- Wyzenbeek Test: This method rubs the fabric back and forth along its warp and weft. It measures the fabric’s resistance to wear by counting the number of double rubs it can endure before showing signs of damage.

- Martindale Test: This approach uses a figure-8 motion to rub the fabric. It provides a more comprehensive assessment of how the fabric will perform under various conditions.

The primary objective of the dry rubbing test is to ensure that the fabric maintains its appearance and functionality over time. This test is particularly important for products like upholstery and workwear, where durability is paramount.

Definition of Wet Rubbing Test

The wet rubbing test assesses colorfastness by measuring how much color transfers from the fabric to a rubbing cloth when wet. This test simulates real-world conditions, such as washing or exposure to moisture.

- The process involves using a standard white cotton cloth, which is rubbed against the test fabric under controlled conditions. The moisture content, friction method, and fabric structure all play significant roles in the results.

I find that the wet rubbing test is crucial for ensuring that fabrics retain their color even after repeated exposure to water. This is especially important for items like clothing and home textiles, where color retention directly affects consumer satisfaction.

Standards for Rubbing Tests

Understanding the standards for rubbing tests is essential for ensuring fabric quality. Various organizations set these standards to maintain consistency and reliability in testing methods.

International Standards Overview

International standards play a crucial role in fabric testing. They ensure that manufacturers and consumers can trust the results of rubbing tests. Here are some key standards:

| Standard | Organization | Description |

|---|---|---|

| BS EN ISO 105 X 12 | European Committee for Standardization (CEN) | Method for determining color fastness to rubbing. |

| ISO 105 X 12 | International Organization for Standardization | Series of standards for color fastness tests, including rubbing. |

These standards help unify testing methods across different regions, ensuring that fabrics meet global quality expectations.

Industry-Specific Standards

Different industries have unique requirements for fabric performance. Industry-specific standards address these challenges effectively. For example:

| Key Factors Influencing Rubbing Fastness | Description |

|---|---|

| Material Characteristics | The quality of fibers or yarns and the surface structure of the fabric significantly impact rubbing fastness. Smoother surfaces tend to have better resistance to color transfer. |

| Dye Selection and Depth of Shade | The type of dye and the intensity of the color applied can affect fastness. Darker shades often show lower rubbing fastness due to higher dye concentration. |

| Dyeing and Printing Techniques | Proper fixation of dyes during these processes is crucial. Unfixed dyes are more likely to transfer during rubbing. |

| Textile Chemicals & Surface Finish | Softening agents and other finishing chemicals can enhance the fabric’s resistance to abrasion and improve overall fastness. |

| Environmental Conditions | Factors like moisture can exacerbate color transfer, making wet rubbing fastness a key consideration. |

By adhering to these standards, manufacturers can ensure that their products meet the specific needs of their target markets.

Methodology of Conducting Rubbing Tests

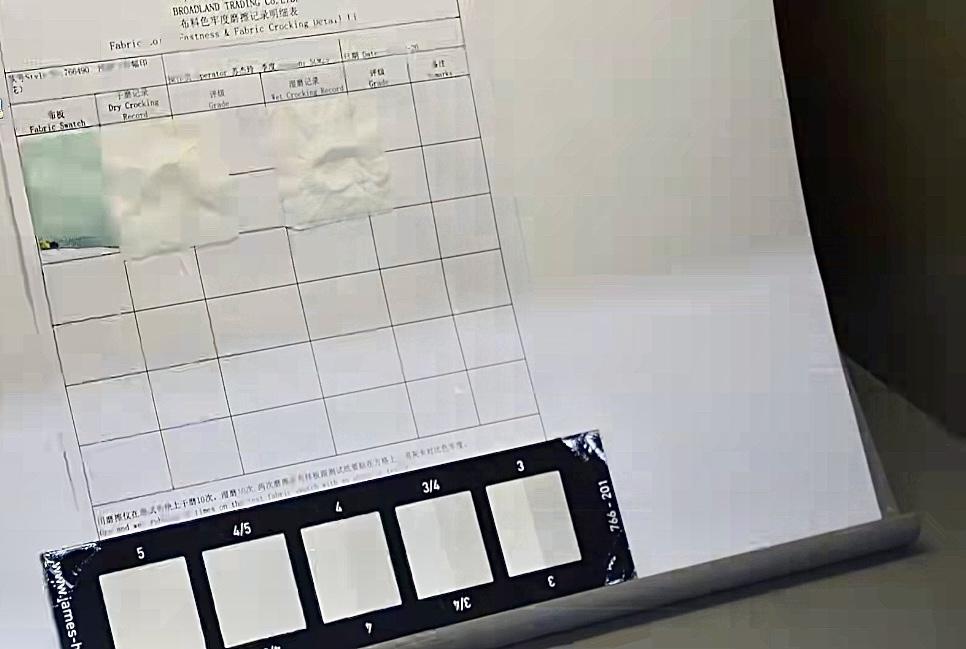

Conducting dry and wet rubbing tests requires specific equipment to ensure accurate and reliable results. I have found that using the right tools significantly impacts the quality of the test outcomes. Below, I outline the essential equipment used in these tests.

Equipment Used

| Equipment Type | Description |

|---|---|

| Rubbing Fastness Tester | Also known as a crock meter, this device tests dye adhesion strength under dry and wet conditions. |

| Dry Rubbing Cloth | This cloth is used for testing dye stability in a dry state. |

| Wet Rubbing Cloth | A pre-wetted cloth simulates actual washing and wet rubbing conditions. |

| Adjustable Weight | This allows for setting the loading pressure to meet different fabric testing needs. |

| Reciprocating Friction Times | Users can set the number of friction cycles according to standard requirements (e.g., 10, 20). |

Using these tools ensures that I can accurately assess the colorfastness of various fabrics. The choice of equipment directly affects the reliability of the results. For instance, a motorized arm ensures precise rubbing against standard abradants, while consistent testing conditions enhance the reliability of the outcomes.

Step-by-Step Testing Process

Performing a standardized dry rubbing test involves several key steps. I follow these procedures to ensure accuracy:

- Clip a 2×7-inch test strip to the four-pound test block, ensuring the abrasive surface faces away from the rubber pad.

- Securely mount the test specimen on the rubber pad of the base plate with the printed side facing up, using the hold-down bracket.

- Thoroughly brush the test strip and test specimen with a camel-hair brush to remove dust or foreign material before starting the test.

- Place the weights over the sample, ensuring the rubber pad of the test block is positioned over the area being tested and both surfaces are clean.

- Preset the tester for ten strokes or any standard number of strokes for the specific test.

For the wet rubbing test, I take additional precautions to ensure consistent results. I carefully select wetting solutions to maintain isotonic conditions and avoid artificially increasing microorganism counts. I also record sampling and processing times to identify any unusual results.

By following these methodologies, I can confidently assess the colorfastness of fabrics, ensuring they meet the necessary quality standards.

Interpreting Rubbing Test Results

Understanding Test Ratings

Interpreting the results of fabric tests is essential for assessing quality. Different rating scales, such as the Wyzenbeek and Martindale tests, provide standardized methods for evaluating fabric durability. These scales allow manufacturers and consumers to gauge wear resistance based on rub counts. For instance, a higher rub count indicates that a fabric can withstand more use before showing signs of wear. Understanding these ratings is crucial when selecting upholstery fabrics.

Implications of Results for Buyers

The implications of rubbing test results extend beyond mere numbers. Prioritizing color fastness is vital for brands in the textile industry. It directly impacts product quality and customer satisfaction. Rigorous testing methodologies, including rubbing tests, help identify potential weaknesses in fabric durability.

Failing rubbing tests can lead to increased production costs, delays in delivery, potential waste of fabrics, and economic losses. Additionally, products that do not meet color fastness standards may cause staining issues and could even harm consumers’ skin, leading to reputational damage and compliance issues.

As a buyer, I always consider these factors when evaluating fabric options. The results of rubbing tests guide my decisions, ensuring that I choose high-quality materials that will satisfy customers and stand the test of time.

Importance of Rubbing Tests for Buyers

Ensuring Product Quality

Rubbing tests play a crucial role in ensuring the quality of fabrics. I rely on tests like the Martindale and Wyzenbeek to assess fabric durability and quality. These tests measure resistance to wear and tear, which is vital for ensuring longevity. A good score in these tests indicates that the fabric will last longer in practical use.

When I evaluate fabrics, I consider the following benefits of rubbing tests:

- They provide a reliable measure of how well a fabric will hold up over time.

- They help identify potential weaknesses in the fabric before it reaches consumers.

- They reduce the likelihood of defects and returns, which can be costly for both manufacturers and buyers.

The Sutherland Rub Tester is a standard tool in the industry for rub testing. This device assesses the durability of labels and materials, helping manufacturers ensure that their products meet quality standards. By implementing these tests, I can trust that the fabrics I choose will perform as expected, minimizing the risk of early wear and buyer dissatisfaction.

Making Informed Purchasing Decisions

Ignoring rubbing test results can lead to poor fabric choices. I have seen firsthand how overlooking these tests can result in selecting fabrics that do not meet durability requirements. This often leads to early wear and buyer dissatisfaction. Without proper test reports, I risk choosing fabrics based on misleading marketing claims, which may not reflect the actual durability of the material.

Here are some risks I consider when evaluating fabric options:

- Selecting fabrics that fail to meet durability standards can lead to premature fabric failure.

- Misleading marketing can result in unexpected issues after purchase.

- Overlooking necessary rub count ranges can cause significant problems down the line.

By prioritizing rubbing tests, I can make informed decisions that align with my quality expectations. This approach not only enhances customer satisfaction but also builds trust in the products I offer. Ultimately, I find that rigorous testing leads to better outcomes for both buyers and manufacturers.

In summary, dry and wet rubbing tests are vital for ensuring fabric quality. They enhance color retention and durability, which boosts consumer satisfaction. I encourage buyers to consider these tests when evaluating fabric products. Here are some key takeaways:

- They prevent color bleeding.

- They support brand reputation.

- They comply with global standards.

FAQ

What is the purpose of dry and wet rubbing tests?

Dry and wet rubbing tests assess fabric colorfastness and durability, ensuring that textiles maintain their appearance during use.

How often should fabrics undergo rubbing tests?

I recommend conducting rubbing tests for new fabric batches or when changing suppliers to ensure consistent quality and performance.

Can I trust the results of rubbing tests?

Yes, when performed according to established standards, rubbing tests provide reliable insights into fabric quality and durability.

Post time: Oct-07-2025