Fabric washing fastness is essential for ensuring high-quality textiles. As an apparel buyer, I prioritize garments that retain their vibrant colors even after numerous washes. By investing in high colorfastness fabric, including durable workwear fabric and medical uniform fabric, I can ensure satisfaction and longevity. Additionally, partnering with a reliable TR fabric supplier allows me to access custom textile solutions that meet my specific needs.

Key Takeaways

- Fabric washing fastness is crucial for maintaining vibrant colors in garments after multiple washes. Choose fabrics with high ratings to ensure durability.

- Understanding ISO and AATCC standards helps buyers make informed decisions. These standards guide the testing of fabric color retention under various conditions.

- Selecting fabrics with high washing fastness reduces risks like fading and reputational damage. This choice enhances customer satisfaction and builds brand trust.

What Is Fabric Washing Fastness?

Fabric washing fastness refers to a textile’s ability to retain its color after being washed. I find this characteristic crucial when selecting fabrics for apparel. It ensures that garments maintain their original appearance even after multiple laundering processes. The assessment of fabric washing fastness involves colorfastness to washing tests, which evaluate how laundering impacts fabric color.

To understand this better, I look at two primary standards: ISO and AATCC. These organizations set the benchmarks for testing fabric washing fastness.

ISO and AATCC Standards

- ISO 105-C06:2010: This standard simulates normal household washing conditions. It evaluates color change and staining after washing under various conditions. The testing includes:

- Single (S) Test: Represents one wash cycle, assessing color loss and staining.

- Multiple (M) Test: Simulates up to five wash cycles with increased mechanical action.

- AATCC 61: This standard also assesses color change and staining but uses a specific washing machine method. It focuses on specific laundering conditions, which can differ from ISO standards.

Here’s a comparison of the two standards:

| Aspect | ISO 105 | AATCC 61 |

|---|---|---|

| Washing Temperature | Range (e.g., 40°C, 60°C) | 49°C |

| Washing Time | Varies (e.g., 30 minutes) | 45 minutes |

| Testing Method | Multifiber test fabric | Specific washing machine method |

| Evaluation Method | Gray scale for color change | Gray scale for color change |

| Focus | Comprehensive conditions | Specific laundering conditions |

Understanding these standards helps me make informed decisions when sourcing fabrics. I know that the differences in temperature and time can significantly affect the results of color fastness tests. A fabric that performs well under ISO conditions may not yield the same results under AATCC conditions. This knowledge is vital for ensuring that the fabrics I choose will meet my quality expectations.

Why Buyers Should Care About Fabric Washing Fastness

Understanding fabric washing fastness is crucial for apparel buyers like me. Poor washing fastness can lead to several risks that affect both consumers and brands.

Risks of poor washing fastness (fading, returns)

When I choose fabrics with low washing fastness, I expose myself to various risks:

- Health Risks: Poor fabric washing fastness can lead to exposure to hazardous chemicals and heavy metals in clothing. These toxicants can permeate the skin and potentially enter the bloodstream, causing systemic health issues.

- Environmental Impact: Low washing fastness contributes to microplastic pollution, which has detrimental effects on our environment.

- Reputational Damage: If my products do not meet quality standards, my brand may suffer reputational damage. This can lead to a loss of consumer trust, which is hard to regain.

- Chemical Exposure: Dye molecules can migrate from fabric to skin, especially under conditions of sweat and friction. This increases the risk of chemical exposure for consumers.

- Financial Penalties: Non-compliance with quality control regulations can lead to significant financial penalties and operational challenges for apparel brands.

These risks highlight the importance of selecting fabrics with high washing fastness ratings.

Benefits of reliable fabrics

On the other hand, choosing fabrics with high washing fastness ratings offers numerous benefits:

- Enhanced Durability: Fabrics that resist fading and color bleeding improve the longevity of garments. This elevates the overall quality perception among consumers.

- Customer Satisfaction: High color-fastness fabrics ensure that colors remain vibrant after washing. This reduces the likelihood of customer dissatisfaction and returns, positively impacting brand reputation.

- Accurate Washing Instructions: By selecting fabrics that maintain their color integrity, I can provide accurate washing instructions. This assurance of quality is crucial for maintaining a positive brand image.

- Consumer Trust and Loyalty: Reliable fabric washing fastness is essential for customer satisfaction. Brands known for good color retention are more likely to gain customer trust and loyalty, as they are viewed as reliable and high-quality.

Our Testing Process for Fabric Washing Fastness

To ensure the quality of fabrics, I follow a systematic testing process for fabric washing fastness. This process consists of four key steps: prepare, simulate washing, dry, and assess. Each step is crucial for obtaining accurate results.

4 key steps: prepare → simulate washing → dry → assess

- Prepare Fabric Samples: I start by cutting the fabric into uniform pieces. This ensures consistency in testing. I also remove any contaminants that could affect the results.

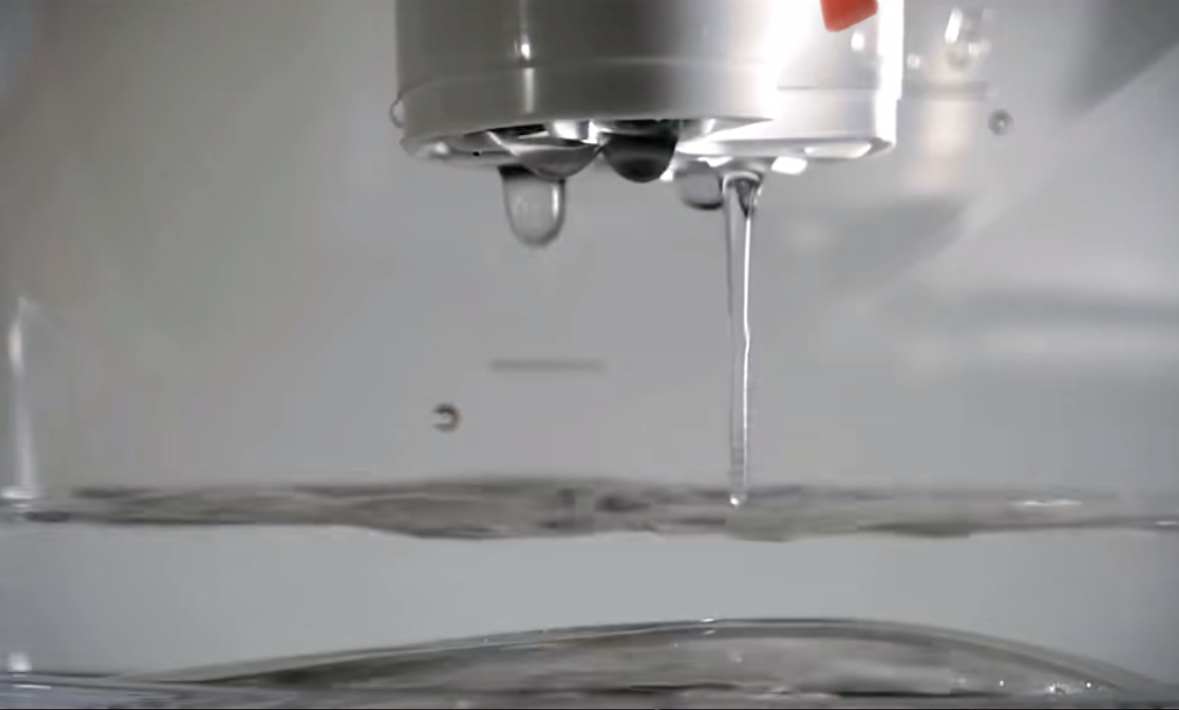

- Simulate Washing: Next, I select the appropriate testing method based on the fabric type and industry standards, such as ISO or AATCC. I prepare a test solution with water, detergent, and any necessary additives. After setting up the washing fastness tester, I place the fabric sample and steel balls in the cup and start the machine. This step simulates real-world washing conditions, allowing me to evaluate how the fabric will perform in everyday use.

Aspect Simulated Laundering Real-World Laundering Control over Variables High (temperature, duration, agitation) Low (varies by machine and cycle) Reproducibility High (consistent conditions) Low (inconsistent due to machine logic) Microfibre Collection >99% effective in closed canister Variable, often not collected effectively - Dry: After the washing simulation, I dry the fabric samples according to standard procedures. Proper drying is essential to prevent any additional color changes that may occur during this phase.

- Assess: Finally, I evaluate the fabric for color changes, bleeding, or fading using standardized scales. This assessment helps me determine the fabric’s washing fastness rating.

Grading scale from 1 (poor) to 5 (excellent)

The grading scale I use to assess fabric washing fastness ranges from 1 to 5. Each grade reflects the fabric’s performance after testing:

| Rating | Qualitative Description |

|---|---|

| 5 | Excellent |

| 4 – 5 | Very Good to Excellent |

| 4 | Very Good |

| 3 – 4 | Good to Very Good |

| 3 | Good |

| 2 – 3 | Fair to Good |

| 2 | Fair |

| 1 – 2 | Poor to Fair |

| 1 | Poor |

Most fabrics I test typically achieve grades of 3-4 or higher after proper processing. High-end brand clothing often meets washing fastness requirements above level 4, thanks to appropriate dyeing and treatment. This rigorous testing process ensures that I select fabrics that not only look good but also maintain their quality over time.

Case Example of Fabric Washing Fastness

As an apparel buyer, I often face challenges when selecting fabrics. One particular experience stands out. I was sourcing materials for a new line of activewear. I wanted vibrant colors that would appeal to my customers. However, I was concerned about how these colors would hold up after repeated washing.

I decided to conduct fabric washing fastness testing on several samples. This testing helped me understand how each fabric would perform over time. I focused on the color fastness ratings, which played a crucial role in my decision-making process. Here’s how the testing impacted my choices:

- Informed Choices: The ratings allowed me to choose fabrics that would maintain their appearance after multiple washes. I learned that higher color fastness ratings are essential for frequently laundered items like activewear. This knowledge influenced my purchasing decisions significantly.

- Quality Assurance: Understanding these ratings ensured that I selected fabrics that would meet my quality standards. I wanted to provide my customers with products that would last, and the testing confirmed which fabrics could deliver that longevity.

- Customer Satisfaction: By prioritizing fabrics with high washing fastness, I could guarantee that my customers would be satisfied with their purchases. This focus on quality helped build trust in my brand.

Ultimately, the fabric washing fastness testing not only solved my initial concerns but also enhanced the overall quality of my product line. I felt confident in my selections, knowing that I had made informed decisions based on reliable data.

Fabric washing fastness plays a vital role in ensuring the quality of apparel. High color retention enhances aesthetic appeal, assures customers of durability, and promotes environmental sustainability. To make informed purchasing decisions, I recommend focusing on dye type and quality, as well as simulating real-life washing conditions.

FAQ

What is the importance of fabric washing fastness?

Fabric washing fastness ensures that colors remain vibrant after multiple washes, enhancing garment durability and customer satisfaction.

How can I test fabric washing fastness?

I recommend using ISO or AATCC standards to simulate washing conditions and assess color retention accurately.

What should I look for in fabric labels?

I check for washing fastness ratings, which indicate how well the fabric will maintain its color after laundering.

Post time: Oct-08-2025