I see how crucial it is to select the right protective garment in healthcare. High contamination rates—up to 96% in some studies—show that even a small mistake with scrub uniform fabric or hospital uniform fabric can put safety at risk. I always check nursing scrub fabrics, medical uniform fabric, and healthcare uniform fabric for protection and comfort. Polyester viscose scrub fabric often offers both.

Key Takeaways

- Waterproof garments block all fluids and offer the highest protection for high-risk healthcare tasks, while water-resistant garments protect against light splashes and suit lower-risk jobs.

- Choosing the right healthcare garment means balancing safety, comfort, and durability to stay protected and comfortable during long shifts.

- Following safety standards and matching your uniform to your job role helps prevent infections and saves money by reducing replacements and workplace risks.

Defining Waterproof and Water-Resistant

What Does Waterproof Mean?

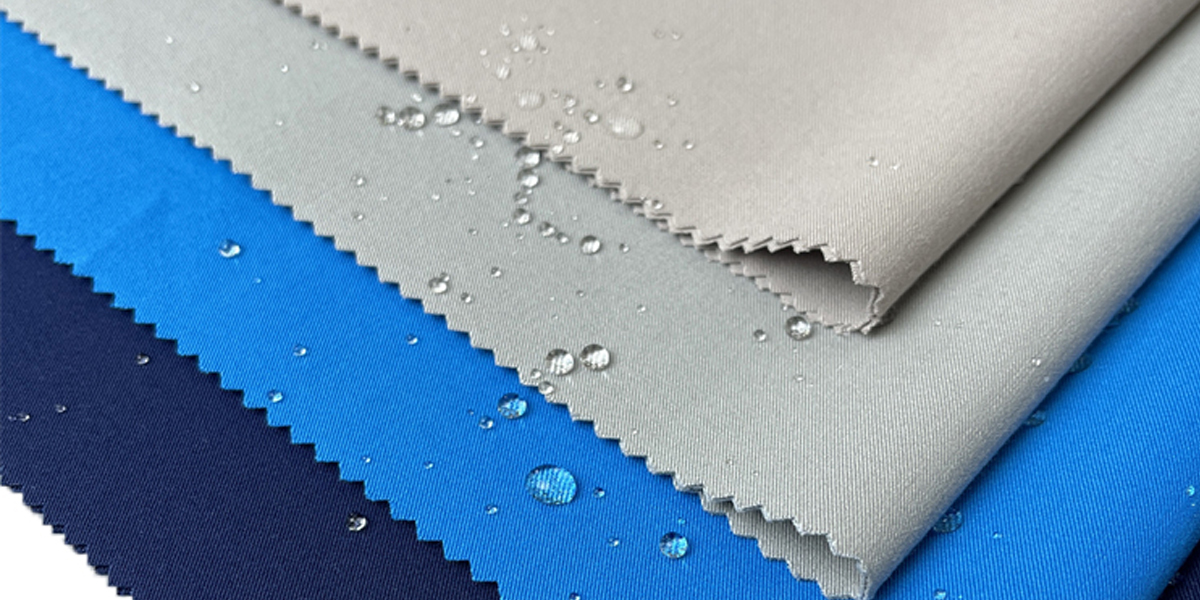

When I look for waterproof healthcare garments, I check for materials and construction that block all liquid from passing through. These garments use advanced fabrics like polypropylene, polyester, or special membranes such as expanded PTFE and polyurethane. I rely on industry standards to confirm true waterproof performance. Some of the most important features and tests include:

- High tensile, burst, and seam strength to prevent leaks.

- Barrier fabrics that resist liquid and viral penetration.

- Seams that are serged, taped, or welded to keep fluids out.

- Compliance with standards like BS EN 13795-1:2019, ASTM F1670/F1671, and ANSI/AAMI PB70:2003.

- Reusable options that maintain protection after many washes.

These technical details ensure that waterproof garments provide a strong shield against blood, bodily fluids, and pathogens.

What Does Water-Resistant Mean?

Water-resistant garments offer some protection but do not block all fluids. I often see these used in lower-risk healthcare settings. Their effectiveness depends on fabric treatments and construction. To measure water resistance, I look at several tests:

| Test Method | What It Measures | Criteria for Water Resistance |

|---|---|---|

| AATCC 42 | Impact penetration | Less than 4.5g water on blotter |

| AATCC 127 | Hydrostatic pressure | 20–50 cm-H2O, less than 1.0g water |

| ASTM D737 | Air permeability | Assesses fabric structure |

The fabric’s thickness, pore size, and any water-repellent finish all affect how well it resists fluids.

Importance of Definitions in Healthcare

Clear definitions help me choose the right garment for each job. In surgery or high-risk care, I need waterproof protection to block all fluids and pathogens. For routine care, water-resistant scrubs may be enough. Knowing the difference keeps me and my patients safer every day.

Protection Level in Healthcare Settings

Fluid and Contaminant Barrier

When I choose garments for healthcare, I always look for strong barriers against fluids and contaminants. A good barrier keeps blood, body fluids, and harmful germs from reaching my skin or clothes. Laboratory tests show that the way a garment fits and the type of fabric matter a lot. For example:

- Scientists used a robotic arm to test how much fluid leaks through the glove-gown area during real movements.

- They measured how much fluid passed through under different conditions, like soaking or spraying, and with different pressures.

- Soaking caused more leaks than spraying. More pressure and longer exposure also increased leaks.

- Most garments tested did not meet the highest standards for water resistance, except in some spray tests.

- The weakest spot was where gloves and gowns meet. Fluids can sneak in if gloves slip or if the fabric channels liquid.

These tests help me understand that even small design details, like the seam at the wrist, can make a big difference in protection. I always check if the scrub uniform fabric and seams are built to block fluids, especially for high-risk tasks.

Infection Control and Safety

I know that what I wear can help stop the spread of infections. Uniforms and scrubs can carry germs from one patient to another or even out into the community. Studies show that up to 60% of hospital staff uniforms have harmful bacteria, including drug-resistant types. In one study, 63% of healthcare workers had at least one spot on their uniforms contaminated. White coats often had dangerous bacteria like MRSA.

- Antimicrobial and fluid-repellent fabrics help lower the risk of spreading infections.

- Special textiles, like those coated with zinc oxide, reduced infection and death rates in burn centers.

- These fabrics also kept dangerous germs off bed linens and patient clothes.

- Nonwoven materials, such as SMS, offer both strong protection and comfort.

I always follow strict laundering rules, but I know that even the best washing may not remove all germs. That is why I prefer garments made with advanced fabrics and finishes for extra safety.

Note: Uniforms with high barrier properties and antimicrobial finishes can help protect both healthcare workers and patients from dangerous infections.

Regulatory Standards

I rely on clear standards to guide my choice of protective garments. In the United States, gowns and other healthcare clothing must meet strict rules. For example, the ANSI/AAMI PB70 standard uses tests like AATCC 42 to rate water resistance. Gowns get classified from Level 1 (basic) to Level 4 (highest protection). Level 3 and Level 4 gowns, like Medline Proxima Aurora and Cardinal Health Microcool, are often stored in hospital stockpiles for emergencies.

- Hospitals keep large supplies of high-filtration gowns and respirators to protect staff.

- Studies show that these garments are a top priority for safety, but their performance can change over time.

- Ongoing research checks how well these garments work after years in storage.

I always check that my garments meet the right level for my job. For surgery or high-risk care, I pick Level 3 or Level 4 gowns. For routine care, lower levels may be enough. Following these standards helps keep everyone safe and supports infection control in every setting.

Breathability and Comfort for Long Shifts

Impact on Heat and Moisture

When I work long shifts, I notice how much heat and sweat can build up under my uniform. If my clothing does not let air pass through, I feel hot and sticky. Studies show that non-breathable gowns can cause heat stress. This makes it harder for me to focus and do my job well. I have seen that breathable protective clothing helps me stay cooler and more comfortable. It also lowers my risk of overheating. Research using infrared thermography shows that sweat builds up in clothing and changes how much heat my body keeps. When moisture in my scrub uniform fabric reaches a certain level, it stops cooling me down, and I start to feel uncomfortable. Fabrics that manage sweat better help me stay dry and keep my body temperature steady.

Balancing Protection with Comfort

I always look for uniforms that protect me from fluids but also let my skin breathe. Good design means I do not have to choose between safety and comfort. Many studies show that comfort drops when clothing feels damp or sticky. I prefer scrub uniform fabric that feels smooth and does not cling to my skin. Designers test fabrics for both protection and comfort. They check how well the fabric covers my body, how it moves with me, and if it works with other gear like gloves and masks. I find that uniforms with the right fit and stretch let me move freely and stay safe.

Tip: Choose garments that cover you well, allow easy movement, and feel dry against your skin for the best balance of comfort and protection.

Considerations for Extended Wear

Wearing protective clothing for many hours can cause problems. I sometimes feel tired, sweaty, or even dizzy after a long shift. My skin can get itchy or sore if my uniform does not fit well or if it traps too much moisture. I have learned that discomfort makes me less likely to wear my gear the right way. Over time, masks and gowns can lose their ability to block germs and keep me comfortable. For example, masks may become harder to breathe through or start to feel wet after a few hours. I always check that my uniform fits well and is made from high-quality materials. This helps me stay safe and comfortable, even during the longest shifts.

| Problem with Extended Wear | How It Affects Me | What I Do About It |

|---|---|---|

| Sweating and heat | Makes me tired, less alert | Pick breathable fabrics |

| Skin irritation | Causes itching or rashes | Choose smooth, soft fabrics |

| Mask discomfort | Harder to breathe, wet | Change masks every few hours |

Durability and Maintenance of Scrub Uniform Fabric

Cleaning and Disinfection

I always look for scrub uniform fabric that stands up to frequent washing and sanitizing. In my experience, the best fabrics are machine washable, quick-drying, and resist stains. Many top brands use blends of polyester, rayon, and spandex. These blends keep their color and shape, even after many washes. I find that wrinkle resistance and antimicrobial properties make my job easier. I do not have to spend extra time ironing or worrying about germs staying on my clothes.

- Scrub uniform fabric should be easy to clean and disinfect.

- Stain resistance helps keep uniforms looking professional.

- Quick-drying materials save time and reduce the risk of bacteria growth.

Wear and Tear Over Time

I notice that some uniforms last longer than others. High-quality scrub uniform fabric features reinforced seams and strong stitching. These details help prevent rips and tears during busy shifts. I have seen that fabrics with four-way stretch and pilling resistance keep their smooth look, even after months of use. Laboratory tests show that reusable gowns can handle up to 75 industrial washes and still meet strength standards. Minimal shrinkage means my uniforms fit well, wash after wash.

| Durability Test | What It Measures | Why It Matters |

|---|---|---|

| Breaking strength | Fabric toughness | Prevents rips |

| Tear strength | Resistance to tearing | Extends garment life |

| Seam strength | Stitch durability | Stops seams from splitting |

| Pilling resistance | Surface smoothness | Keeps fabric looking new |

| Colorfastness | Color retention | Maintains professional look |

Longevity in Healthcare Use

I rely on scrub uniform fabric that lasts through daily wear and frequent cleaning. Blends like 65% polyester and 35% cotton resist spills and keep their shape over time. Reinforced stitching and wrinkle resistance add to the fabric’s lifespan. I appreciate that these uniforms stay comfortable and breathable, even after long shifts. The low-maintenance nature of these fabrics lets me focus on patient care, not uniform upkeep.

Tip: Choose scrub uniform fabric with proven durability and easy-care features to save money and time in the long run.

Cost-Effectiveness in Healthcare Garments

Upfront Costs vs. Long-Term Value

When I choose healthcare garments, I look at more than just the price tag. Waterproof garments often cost more at first. Water-resistant options usually have a lower upfront cost. I have learned that the true value comes from how long the garment lasts and how well it protects me. If a garment keeps its shape and barrier after many washes, I save money over time. I do not need to replace it as often. I also avoid extra costs from workplace injuries or infections. A higher-quality garment can mean fewer sick days and better safety for everyone.

Replacement Frequency

I track how often I need to replace my uniforms. Water-resistant garments may wear out faster, especially after repeated washing and exposure to harsh chemicals. Waterproof garments, especially those made with strong seams and advanced fabrics, last longer. I have seen that some reusable gowns can handle dozens of washes without losing their protective features. This means I buy new uniforms less often. Fewer replacements help my department stay within budget and reduce waste.

Budget Considerations

I work with my team to plan our uniform budget each year. We focus on both cost and safety. Our process includes:

- Reviewing supply costs and quality for each garment type.

- Planning for unexpected needs, like outbreaks or supply shortages.

- Making sure all uniforms meet safety and regulatory standards.

- Assigning clear responsibility for managing funds and supplies.

- Adjusting our plan as prices or needs change.

Note: Good communication and regular reviews help us balance cost efficiency with patient and staff safety. This approach supports both our financial health and our commitment to high-quality care.

Factors Unique to Healthcare Environments

Exposure Risk Levels

When I work in healthcare, I see that not all jobs carry the same risk. The CDC explains that my exposure risk depends on the disease stage, how sick the patient is, and what tasks I perform. For example, if I care for a patient with a contagious illness, I face a higher risk than someone who only interviews patients. The way germs spread—by touch, droplets, or through the air—also changes what kind of protection I need. I always think about these risks before choosing my garments. In my experience, emergency department nurses often face more unpredictable situations, while ICU nurses may have stricter routines and better compliance with protective gear.

Role-Specific Needs

I know that my job role shapes what I need from my uniform. Here are some things I consider:

- Protection against blood, body fluids, and viruses.

- Proper fit and sizing for comfort and movement.

- Easy donning and doffing to avoid contamination.

- Thermal comfort to prevent heat stress.

- Acceptance by staff and cost-effectiveness.

- Maintenance and safe areas for changing clothes.

I also look for garments with strong seams and closures. I want materials that meet fluid resistance standards. I avoid “one size fits all” because I need a good fit for safety and comfort. I follow CDC and OSHA guidelines for my specific tasks.

Tip: Always match your garment features to your daily tasks and the risks you face.

Compliance with Healthcare Regulations

I follow strict rules for cleaning and maintaining my uniforms. Regulations like EN14065 and HTM 01-04 require industrial laundering with careful hazard controls. Hospitals use special laundry processes to kill germs and prevent recontamination. I avoid washing my uniforms at home because studies show that home machines can spread infections. Some hospitals use antimicrobial fabrics, but results vary. I trust regulated laundering and proper garment features to keep me and my patients safe.

Choosing the Right Garment for Your Role

Matching Garment Type to Job Function

When I choose what to wear at work, I always think about my daily tasks. My job in healthcare can change from one shift to the next. If I work in surgery or handle a lot of body fluids, I need the highest level of protection. Waterproof garments give me that shield. They block all fluids and keep me safe during high-risk procedures. If I work in outpatient care or do routine check-ups, I may not need as much protection. Water-resistant garments work well for these jobs. They protect me from small splashes and keep me comfortable. I always match my garment to my job function. This helps me stay safe and do my best work.

Practical Tips for Selection

I use a simple checklist when I pick my uniforms. Here are some tips that help me make the right choice:

- I check the level of fluid exposure in my daily tasks.

- I look for garments that fit well and allow me to move easily.

- I read the labels to see if the fabric meets safety standards.

- I ask my team about their experiences with different brands.

- I choose scrub uniform fabric that feels comfortable and stands up to many washes.

- I make sure the garment is easy to put on and take off.

Tip: Always try on new uniforms before buying in bulk. A good fit and feel can make a big difference during long shifts.

When to Choose Waterproof vs. Water-Resistant

I often use a decision matrix to help me decide between waterproof and water-resistant garments. This table helps me compare the key factors:

| Decision Factor | Waterproof Garments | Water-Resistant Garments |

|---|---|---|

| Nature of Work | High-risk, lots of fluid exposure | Low-risk, occasional splashes |

| Comfort | Maximum protection, less breathable | More breathable, lighter, more comfortable |

| Mobility | Heavier, may limit movement | Lighter, easy to move in |

| Durability | Very durable with proper care | Durable, but coatings may wear off |

| Cost | Higher upfront cost, lasts longer | Lower cost, may need more frequent replacement |

If I expect to face a lot of fluids or work in a high-risk area, I always pick waterproof garments. They give me peace of mind and meet strict safety rules. If my job involves less risk, I choose water-resistant options. They keep me cool and let me move freely. I also think about my budget and how often I need to replace my uniforms. This helps me find the best balance between safety, comfort, and cost.

I choose waterproof garments for high-risk roles because they offer the best protection. Water-resistant options work well for comfort and lower-risk tasks. Studies show that comfort and safety improve patient outcomes. I always match my uniform to my job, follow infection prevention policies, and consider cost, comfort, and regulatory needs.

FAQ

What is the main difference between waterproof and water-resistant garments?

I see waterproof garments block all fluids. Water-resistant garments only stop light splashes. I always check the label for the right level of protection.

How do I know if my uniform meets healthcare safety standards?

I look for certifications like ANSI/AAMI PB70 or EN 13795. These show the garment passed strict tests for fluid resistance and safety.

Can I wash waterproof and water-resistant uniforms at home?

I always follow hospital guidelines. Most hospitals require industrial laundering. Home washing may not remove all germs or keep the garment’s protective features.

Post time: Jun-18-2025