Modal fiber is a kind of cellulose fiber, which is the same as rayon and is a pure man-made fiber. Made from wood slurry produced in European shrubs and then processed through a specialized spinning process, Modal products are mostly used in Production of underwear. Modal can also demonstrate its weavability during the weaving process of woven fabrics, and can also be interwoven with yarns of other fibers to weave into a variety of fabrics. Modal products have broad development prospects in modern clothing.

Modal knitted fabrics are mainly used to make underwear. However, modal has the characteristics of silvery luster, excellent dyeability and bright color after dyeing, which are enough to make it suitable for outerwear. Because of this, modal is increasingly becoming a material for outerwear and decorative fabrics. In order to improve the shortcomings of poor stiffness of pure modal products, modal can be blended with other fibers and achieve good results. JM/C(50/50) can make up for this shortcoming. Blended fabrics woven with this yarn make the cotton fibers more supple and improve the appearance of the fabric.

Main features

1. The raw material of Modal fiber comes from natural wood and can be naturally degraded after use.

2. The fineness of Modal fiber is 1dtex, while the fineness of cotton fiber is 1.5-2.5tex, and the fineness of silk is 1.3dtex.

3. Modal fiber is soft, smooth, bright in color, the fabric feels particularly soft, and the cloth surface has a bright luster. It has better drape than existing cotton, polyester, and rayon. It has luster and hand feel. It is a natural mercerized fabric.

4. Modal fiber has the strength and toughness of synthetic fibers, with dry strength of 3.56cn/tex and wet strength of 2.56cn/tex. The strength is higher than that of pure cotton and polyester cotton, which reduces breakage during processing.

5. The moisture absorption capacity of Modal fiber is 50% higher than that of cotton fiber, which allows Modal fiber fabric to stay dry and breathable. It is an ideal close-fitting fabric and health-care apparel product, which is beneficial to the human body's physiological circulation and health.

6. Compared with cotton fiber, Modal fiber has good morphological and dimensional stability, making the fabric naturally wrinkle-resistant and non-ironing, making it more convenient and natural to wear.

7. Modal fiber has good dyeing performance and remains as bright as new after many washes. It is also moisture-absorbent and has good color fastness. Compared with pure cotton, it is more comfortable to wear and does not have the shortcomings of pure cotton clothing such as fading and yellowing. . Therefore, the fabrics are brightly colored and have stable wearing properties. After being washed together with cotton fabrics for 25 times, the hand feel will become harder with each wash. Modal fiber fabrics are just the opposite. They become softer and brighter the more they are washed.

The main purpose

Modal fiber meets the requirements of the ECO-TEX standard, is physiologically harmless and biodegradable. It has special advantages for textiles that are in direct contact with the body, and the fine denier fiber gives knitted fabrics comfortable wearing properties, soft hand feel, flowing drape, attractive luster and high moisture absorption. Because of this, many warp knitting and weft knitting manufacturers have begun to use this fiber as raw material to produce daywear and pajamas, sportswear and casual wear, and also for lace. This fabric has a particularly ideal effect when used with other close-fitting clothing, allowing your skin to always feel dry and comfortable. Even after washing, it can still maintain a certain degree of water absorption and light and soft feeling. This is all due to the smooth surface of the material. The surface prevents the fibers from tangling with each other during the cleaning process.

Which is better, modal fabric or pure cotton fabric?

Modal fabric has the characteristics of softness, breathability, and good hygroscopicity. It is more wear-resistant and less prone to shrinkage than pure cotton. It has better anti-wrinkle performance, has higher gloss and softness than pure cotton, and is more comfortable to the touch.

Pure cotton fabric is a natural fiber that is soft and comfortable, has good breathability, is also very hygroscopic, is skin-friendly, and is not prone to static electricity.

In addition, modal fabrics are better than pure cotton in terms of softness, comfort, hygroscopicity, wear resistance, easy dyeing, and high gloss. Pure cotton fabrics are better in terms of cost and durability. Therefore, modal fabrics and pure cotton fabrics have their own applicable scenarios, and they need to be selected according to specific circumstances.

Which is better, modal fiber or polyester fiber?

Modal and polyester each have their own pros and cons. In appearance, Modal fabric is delicate, smooth, and colorful, just like silk fabric. Secondly, the modal fabric feels very good and feels very comfortable to wear. Moreover, it is anti-wrinkle and does not require ironing, which has advantages that other fabrics cannot match. Polyester fiber has poor hygroscopicity, poor air permeability, poor dyeing performance, weak water absorption, poor melt resistance, and easily absorbs dust. However, if we consider aspects such as washability, dirt resistance, and wear resistance, polyester fiber is better. Therefore, we need to choose appropriate fabrics based on specific usage scenarios and needs.

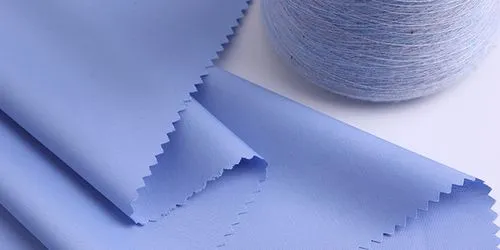

We offer a variety of colors in our polyester modal fabric, perfect for crafting stylish shirts.

Post time: Oct-16-2023