Yarn dyed fabric is created by dyeing individual yarns before they are woven, a process that allows for the creation of intricate and lasting patterns, such as uniform checks. This method ensures superior colorfastness and distinct, clear designs. The market for yarn dyed fabric is substantial, with an estimated size of USD 4.80 billion in 2024, and is projected to experience significant growth. This woven yarn dyed fabric is highly valued for its quality and aesthetic appeal.

The yarn dyed fabric process involves carefully selecting and dyeing yarns, which are then meticulously woven together to form the final textile. This technique is favored by yarn dyed fabric manufacturers for its ability to produce textiles with exceptional depth and durability. One popular application is yarn dyed oxford fabric, known for its characteristic basket weave and robust nature, making it ideal for shirting and other apparel.

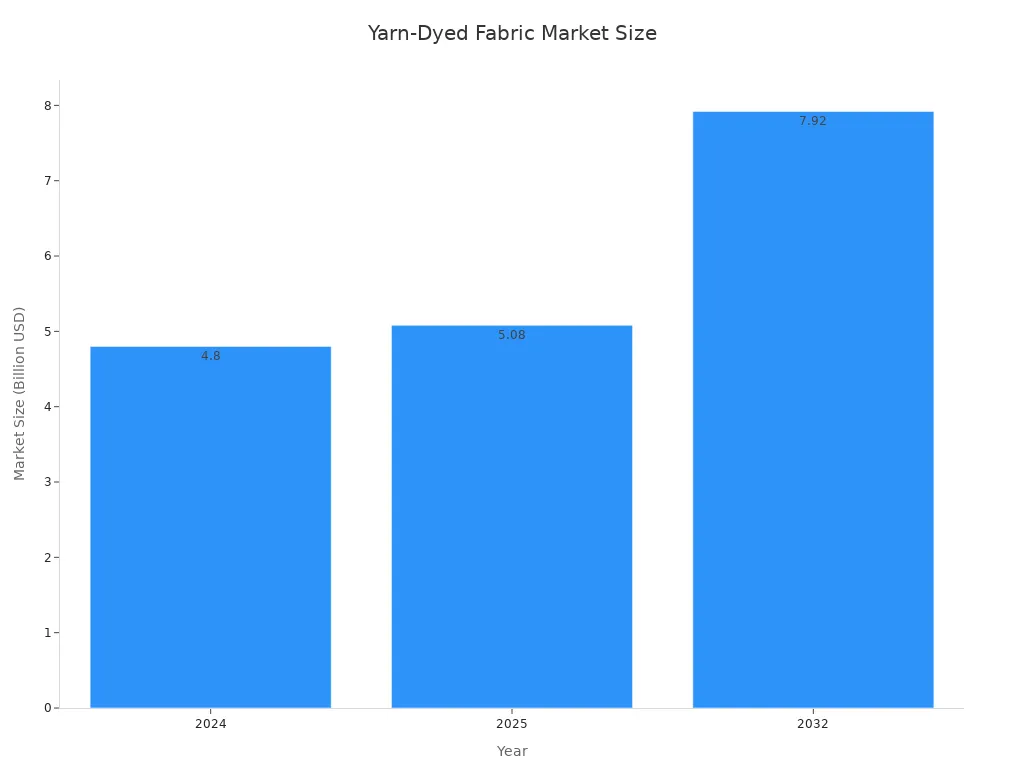

| Metric | Value |

|---|---|

| Estimated Market Size (2024) | USD 4.80 billion |

| Expected Market Size (2025) | USD 5.08 billion |

| Projected Market Size (2032) | USD 7.92 billion |

| CAGR (2025-2032) | 6.45% |

Key Takeaways

- Yarn-dyed fabric is made by coloring individual threads before weaving. This makes patterns clear and colors last longer.

- This fabric is strong and keeps its color well, even after many washes. It is good for uniforms and other clothes that need to last.

- Yarn-dyed fabric allows for many different designs, like stripes and checks. This makes clothes look nice and unique.

Understanding Yarn-Dyed Fabric

Defining Yarn-Dyied Fabric

Yarn-dyed fabric is a woven material. Manufacturers color individual yarns before weaving them into the final textile. This process sets it apart from piece-dyed fabric. With piece-dyed fabric, the entire textile receives dye after weaving from an undyed, greige state.

Unique Characteristics of Yarn-Dyed Fabric

Yarn-dyed fabric possesses several unique characteristics. The dyeing process involves coloring individual yarns before weaving them into a pattern. This method ensures excellent color retention. Colors tend to fade less quickly compared to piece-dyed fabric. The weave design, such as stripes or plaids, appears on both sides of the fabric. This differs from printed fabric, which has a distinct right and wrong side. Creating designs in yarn-dyed fabric requires additional time, planning, and engineering during the weaving process. The fabric often has a soft feel and a gentle drape. It presents a relaxed, comfortable look. Its price point can be slightly higher due to the more involved production process.

The front and back of the cloth may not perfectly match. Fabrics often feature slightly raised textures woven into them. They tend to look more artisanal and rustic. Sophisticated engineering efforts during weaving create these designs. Most fabrics with stripes, checks, plaids, gingham, dotted, or cross patterns are yarn-dyed. Denim and fabrics with Dobby type weaving, which includes tiny crosses, dots, or lines, are common examples of yarn-dyed fabrics.

Yarn-dyed fabric also offers distinct aesthetic and functional properties. Designs are an integral part of the fabric. This is because manufacturers dye the yarns before weaving. This often results in double-sided fabric. The design is visible and useful on both sides. The fabric possesses an “old-world charm and character.” It appeals to styles combining southwestern, tribal, native, and eastern cultures.

| Characteristic | Yarn-Dyed Fabric | Other Acrylic Fabrics (Piece-Dyed) |

|---|---|---|

| Production Process | Yarns are dyed first, then woven into fabric. This allows for intricate, detailed designs. | Fabric is woven first with undyed yarns, then dyed as a whole. This is simpler and cost-effective for solid colors. |

| Visual Effects | Rich, vibrant, sharp, and clear patterns have a three-dimensional quality. It offers unique texture and depth. | A more uniform and flat appearance is ideal for solid colors. It lacks intricate patterns and visual depth. |

| Colorfastness | It has better colorfastness. Color is deeply embedded, making it less likely to fade from washing or sunlight. Patterns are more resistant to wear. | It is more prone to fading, especially without proper color-fixing agents. Color can bleed or transfer. |

| Durability & Quality | It is generally higher quality. Patterns are less likely to wear off or distort. It withstands multiple washes without significant fading or degradation. | It can be durable but is more susceptible to color changes and wear. This is especially true with harsh washing or prolonged sunlight. |

| Applications | High-end fashion items like shirts, blouses, and dresses use it. Home decor items such as curtains and upholstery also use it due to intricate patterns and elegance. | Sportswear, underwear, and basic clothing items use it where solid color and simplicity are preferred. It is cost-effective for mass production. |

Common Patterns in Yarn-Dyed Fabric

Yarn-dyed techniques create a variety of common patterns.

- Solid: Immersion dyeing with consistent temperature and dye concentration achieves this pattern.

- Semi-Solid: Gently manipulating yarn during immersion or kettle dyeing creates subtle tonal shifts.

- Tonal: Kettle dyeing distributes colors unevenly, or dip dyeing creates gradual transitions.

- Variegated: Hand painting different sections of yarn with various colors produces this. Resist dyeing also creates a mix of colors.

- Speckled: Sprinkling dry or diluted dye powder onto damp yarn creates crisp dots and bursts of color.

- Gradient/Fade/Ombre: Hand painting allows for controlled transitions. Dip dyeing slowly lowers yarn into a dye bath at varying depths for this effect.

- High-Contrast Multicolor: Hand painting achieves distinct color placement. Resist dyeing creates bold, unpredictable mixes.

The Manufacturing Process of Yarn-Dyed Fabric

Yarn Selection and Preparation

The creation of yarn-dyed fabric begins with careful yarn selection. Manufacturers choose specific fiber types and yarn counts to achieve desired fabric characteristics. Cotton yarns are popular for their softness, breathability, and absorbency. Combed cotton, known for its smoothness and strength, appears in premium fabrics like dress shirts. Carded cotton, a less expensive option, offers a slightly rougher texture for casual fabrics such as denim. Environmentally conscious producers often select organic cotton, grown without pesticides. Polyester yarns provide strength, durability, and resistance to wrinkles and shrinkage. Filament polyester, smooth and shiny, suits sportswear, while staple polyester offers a more natural texture for casual wear. Wool yarns, natural and warm, provide insulation and luxurious textures.

Cotton yarns come in various counts and twists. These factors significantly influence the fabric’s final texture and appearance. For example, a higher count cotton yarn produces a finer, smoother fabric. Conversely, a lower count yarn results in a more textured, rustic look.

After selecting the yarns, preparation for dyeing begins. Manufacturers often rewind yarn into larger skeins, though using yarn as it comes is also acceptable. They secure skeins in at least six places using a figure-8 style tie with waste yarn to prevent tangling. For larger skeins, ties are placed approximately every 12 inches. Presoaking the yarn is a crucial step, especially for protein fibers like wool, cashmere, silk, and mohair. These fibers have a scaly cuticle that slows water absorption. Presoaking allows water to permeate the yarn’s core, facilitating even dye absorption through diffusion. Dye molecules move from areas of high concentration to low concentration, bonding with the fiber beneath the outer cuticle.

To presoak, one fills one side of a sink with about three inches of cold water and adds a cup of vinegar. Workers submerge tied yarn hanks in the water, gently pushing all yarn under the surface for 30-60 seconds to ensure thorough wetting. The yarn soaks for at least 30 minutes, or up to an hour, while preparing dyes. Alternatively, one can open the yarn hank into a large circle and add a shower curtain ring as a handle, ensuring it slides freely. They create loose figure-8 ties with cotton or spare yarn, replacing original tight ties to avoid undyed sections. Then, they fill a basin with water and add 1/2 cup of white vinegar. The prepped skeins go into the basin and soak for 30 minutes, or until no bubbles appear when squeezed. Soaking for more than two hours can dull the yarn.

Methods of Yarn Dyeing

Several techniques exist for dyeing yarns. Common methods include immersion dyeing, where yarn fully submerges in a dye bath. Pour-over dyeing involves pouring dye directly onto the yarn. Dip or gradient dyeing creates gradual color transitions. Hand-painting dye directly onto the skein allows for intricate, custom designs.

Industrial processes also employ specific methods. Skein dyeing involves forming yarn into a skein and then immersing it in a dyeing machine. Packaging dyeing winds yarn onto a perforated bobbin, places it in a package dyeing machine, and circulates dye solution through it. Warp beam inclination winds warp yarns onto perforated loops, installs them in a dyeing machine, and circulates dye solution for dip dyeing. Yarn dyeing, also known as ball dyeing, bundles raw yarn into a spherical shape, repeatedly immerses, rolls, and air-oxidizes it in a tank to achieve indigo dyeing.

Yarn-dyed fabric offers several advantages. It possesses a strong three-dimensional sense, achieved by using different colored yarns and fabric structures. It boasts good color fastness due to thorough dye penetration. The fabric is rich in color, as weaving with multi-shuttle and multi-arm machines allows for diverse fiber and yarn count combinations. This results in a unique style with distinctive and beautiful designs. High-temperature treatment during production ensures dyes and fibers combine tightly, leading to excellent washability and durability without discoloration or wear.

However, yarn-dyed fabric also has disadvantages. Its high cost stems from significant losses in dyeing, weaving, and post-processing, lower production capacity compared to white fabric, and high investment and technical requirements. Most dyes are not light-resistant, making the fabric susceptible to fading with prolonged sun exposure. The complex multi-process production results in a long production cycle, extending manufacturing and delivery times. Solution-dyed yarns, a specific type, require large lot sizes, typically 4500 KGS or 10000 Lbs. They also have limited color availability, making custom colors impossible without very large quantities. Sometimes, they may exhibit slightly lower tenacity depending on the fiber produced.

Drying and Winding Dyed Yarns

After dyeing, manufacturers unload the yarn packages from the carrier. They then dry the yarn to achieve the correct moisture content. Radio-frequency (RF) drying is the most common method. This technique dries packages evenly from the inside out using electromagnetic energy.

Once dry, winding prepares the dyed yarns for weaving. For stronger yarns, such as 60/2 silk, direct winding onto pirns or cones is possible. For weaker yarns, winding onto a spool or bobbin first is recommended for smoother winding. A double-ended electric bobbin winder with a foot pedal, regulated for speed, works well. This is especially true when winding onto spools or bobbins first for delicate yarns, then onto cones or pirns. A manual ball winder is also effective, particularly when an index card prevents the ball from collapsing. Yarns can also be wound into a hank using a book or into center-pull balls using a nostepinne.

Weaving Yarn-Dyed Fabric

Weaving yarn-dyed fabric involves interlacing the pre-dyed warp and weft yarns to create the desired pattern. This process requires precision to ensure the colors align correctly and form the intended design. Weavers carefully set up the loom with the various colored warp yarns. They then introduce different colored weft yarns according to the pattern specifications.

Weaving intricate patterns in yarn-dyed fabrics presents specific challenges. Creating very fine and detailed patterns is difficult due to the inherent nature of the yarn-dyeing and weaving process. This leads to limited availability of certain intricate patterns, as they are harder to achieve. Pattern matching also poses a challenge; even minor deviations in weaving can lead to mismatches, especially for complex or large patterns. Weavers must exercise extreme care to ensure correct yarn alignment for seamless patterns, though irregularities can still occur.

Finishing Processes for Yarn-Dyed Fabric

After weaving, yarn-dyed fabric undergoes several finishing processes to enhance its quality and performance. These steps include cleaning, scouring, and bleaching to remove impurities and prepare the fabric. Mercerizing, a chemical treatment, improves strength, luster, and dye uptake. Sometimes, additional dyeing occurs at this stage, though the primary dyeing happens at the yarn stage. Special finishing treatments further enhance the fabric. These can include durable press finishes to reduce wrinkling, water repellency treatments, and flame resistance applications. Shrinkage control processes also ensure dimensional stability.

Benefits of Yarn-Dyed Fabric for Uniform Checks Fabric Suppliers

Superior Colorfastness and Durability

Yarn-dyed fabric offers significant advantages in color retention and strength. Manufacturers dye individual yarns before weaving. This process embeds color deeply within the fibers. Consider the difference between a carrot and a radish. Solution-dyed fabrics, like a carrot, have consistent color throughout. Piece-dyed fabrics, like a radish, only have color on the surface. This built-in color significantly improves colorfastness. It also increases durability, especially after industrial laundering. Yarn-dyed fabrics resist fading and bleeding. They maintain their vibrant color longer than fabric-dyed materials. The dyeing process also makes fibers more tightly held together. This results in stronger fabric, more resistant to wear and tear.

Design Versatility and Depth

Yarn-dyed fabrics provide extensive design possibilities. They incorporate colored yarns into the weaving process. This creates a vibrant interplay of colors and patterns. The fabric becomes rich in texture and visual interest. It achieves a stunning three-dimensional effect. This depth of color from multiple yarns makes patterns appear dynamic and lively. Yarn dyeing allows for intricate patterns like stripes, checks, and jacquards. It supports a wide range of color combinations. This method facilitates contrasting or monochromatic schemes. Different dyeing techniques also create unique textures. This elevates the fabric’s overall look.

| Feature | Yarn-Dyed Fabric | Piece-Dyed Fabric |

|---|---|---|

| Dyeing Process | Yarn dyed before weaving | Fabric dyed after weaving |

| Color Depth | Richer, more vibrant colors; deeper dye penetration | Lighter colors; dye coats the surface |

| Pattern Complexity | More intricate and unique patterns | Less complex patterns |

| Design Versatility | Allows for detailed, eye-catching designs | Limited in pattern complexity |

| Durability | Better colorfastness, more resistant to fading | Colors may fade or look less vibrant over time |

Yarn-Dyed Fabric vs. Other Dyeing Methods

Yarn-dyed fabric stands apart from other dyeing methods. Its unique process of pre-dyeing yarns offers distinct benefits. Unlike piece-dyed fabrics, where dye coats the surface, yarn-dyed materials have color deeply integrated. This results in superior color depth and vibrancy. The method allows for more intricate and unique patterns. Piece-dyed fabrics typically offer less complex designs. This difference in process directly impacts durability and design versatility.

Ideal Applications for Uniforms

Yarn-dyed fabric is highly suitable for uniform production. It offers a wide range of hues and tones. This enables colorful and aesthetically pleasing garments. The process ensures consistent color saturation across the fabric. This leads to a uniform appearance. Its design flexibility facilitates intricate patterns and multicolored designs. These add depth and detail to the fabric. For example, school uniforms, like skirts and jumper dresses, often use yarn-dyed properties for plaid patterns and wrinkle resistance. Uniform fabrics require durability, abrasion resistance, and colorfastness. Yarn-dyed materials meet these demands effectively.

Yarn-dyed fabric consistently offers distinct advantages. It excels in color vibrancy, durability, and design versatility. These qualities make it a valuable choice for high-quality uniform production. Suppliers find it ideal for creating long-lasting, aesthetically pleasing garments. Its inherent strength and colorfastness meet rigorous demands.

FAQ

What is the main difference between yarn-dyed and piece-dyed fabric?

Yarn-dyed fabric uses pre-dyed yarns woven into patterns. Piece-dyed fabric is woven first, then dyed as a whole. This creates distinct color depth and pattern integration.

Why is yarn-dyed fabric more durable?

Dye penetrates individual yarns deeply before weaving. This process embeds color throughout the fibers. It results in superior colorfastness and increased resistance to fading and wear.

What patterns are common in yarn-dyed fabric?

Common patterns include solids, semi-solids, tonals, variegated, speckled, and gradients. Weavers create these by interlacing different colored yarns.

Post time: Jan-27-2026