Bari mu san tsarin masana'antar rini!

1. Rage girman kai

Wannan shine mataki na farko a masana'antar da ke mutuwa. Da farko, ana yin gyaran girman. Ana saka yadi mai launin toka a cikin babban ganga da ruwan zafi mai tafasa don wanke ragowar da ke kan yadi mai launin toka. Daga baya kuma a guji lalacewa yayin da ake mutuwa. Ana amfani da ganga da ruwan zafi yayin gyaran girman. Don haka wannan tsari yana ɗaukar ɗan lokaci.

2. Saitin masana'anta mai launin toka

Yawanci faɗin yadin launin toka shine mita 1.63, amma muna buƙatar faɗin samfurin mita 1.55. Don haka yadin launin toka yana tafiya cikin zafin jiki mai zafi daga digiri 160 zuwa 180 don sarrafa faɗin. Wannan tsari ana kiransa saitin zafi na yadin launin toka.

3.Yin waƙa

Tsarin da ke gaba a masana'antar rini shine yin waƙa. Kuna iya ganin wutar. Wannan wuta ce. Yadin launin toka yana ratsawa ta cikin wuta don cire launin ruwan da ke saman sa. Don haka a tsaftace shi a shirya shi don rini.

4.Rage Nauyi

Tsarin da ke gaba a masana'antar rini shine rage nauyi. Kafin rini, zare yana buƙatar ya zama siriri da alkali. Da wannan tsari, za mu iya sarrafa nauyin yadi kuma mu sa shi ya yi laushi. A lokaci guda, muna cire launin ruwan kasa daga saman don hana lahani na rini.

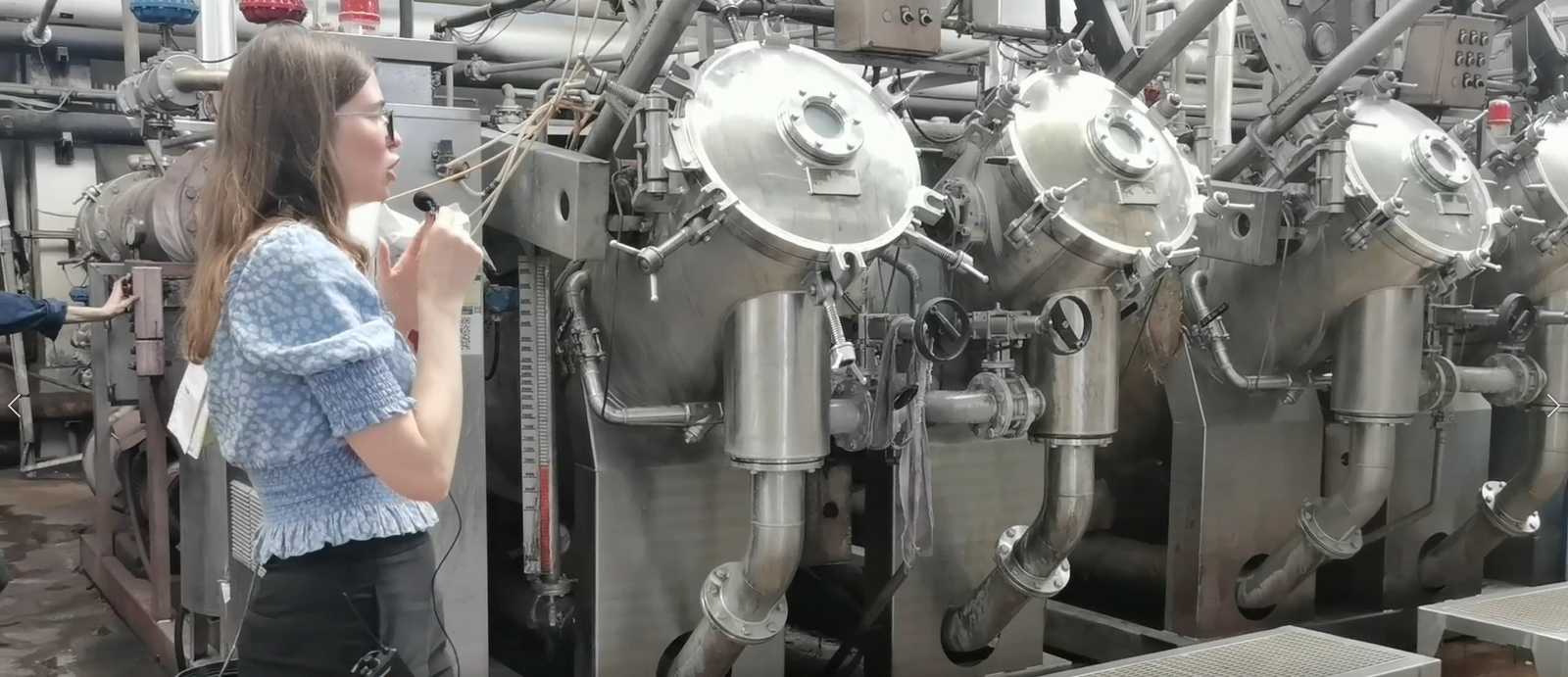

5.Rini na Rukunin/Rukunin Ruwa

Rini ko rini mai yawa, wannan shine babban tsari a masana'antar rini. Don rini na zaruruwan polyester, muna buƙatar dice mai warwatse da zafin digiri 80. Yana ɗaukar awanni 4 don rini da zaruruwan polyester don rini na viscose muna buƙatar rini mai amsawa da zafin digiri 85. Yana ɗaukar awanni 3. Sannan muna buƙatar adana zafi na rabin sa'a. Bayan haka muna buƙatar sabulu da tan biyar na ruwa don cire rini da ƙazanta. Wasu abokan ciniki suna da buƙatu na musamman akan matakin PH da matakin samar da muhalli na masana'anta. Don haka muna ƙara ƙarin lokacin sabulu don cika buƙatun abokan ciniki.

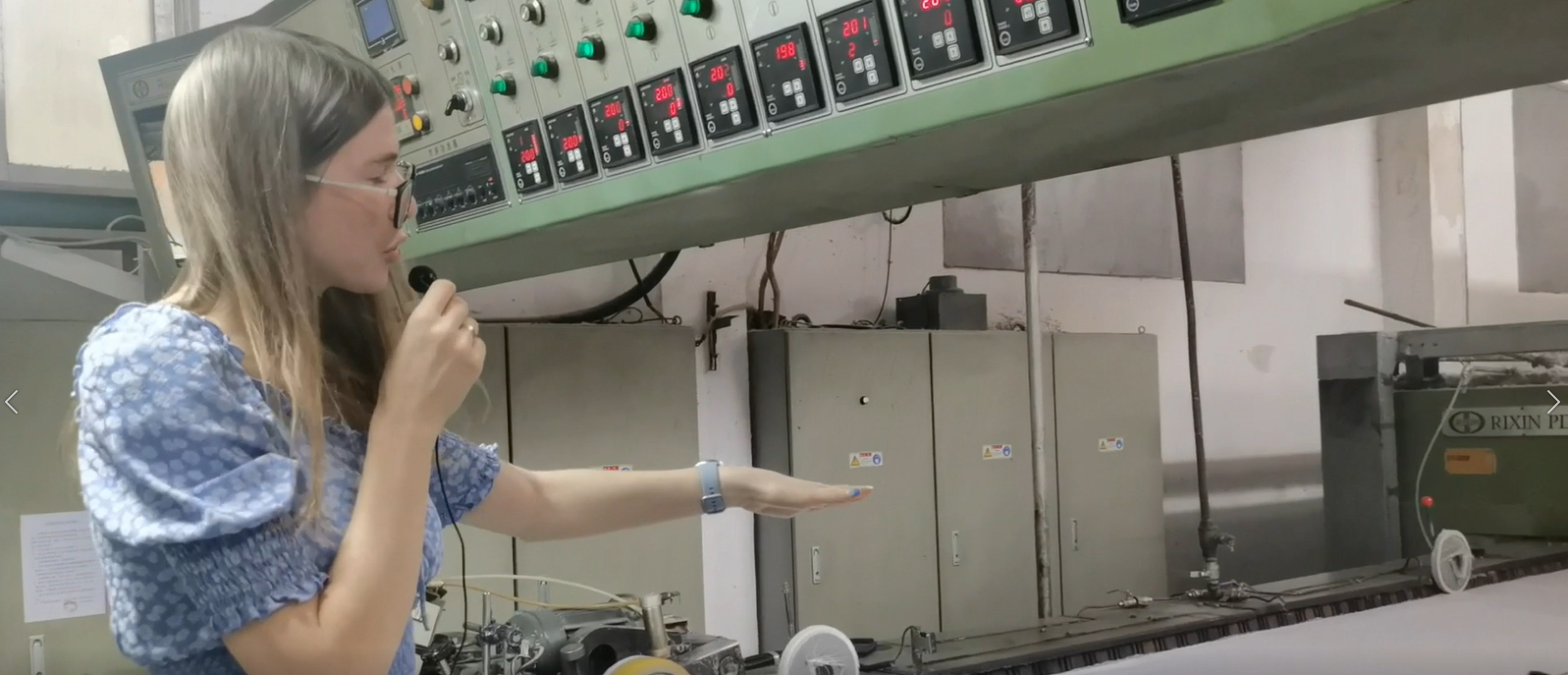

6.Saitin mai

Bayan an gama rini, za a sami injin saita mai na silicone. Man silicone zai shiga cikin zaren yadi kuma ya rufe shi gaba ɗaya. Don haka, za mu iya daidaita ƙarfin yadi da jin hannun. Bayan haka, yadi zai shiga cikin tanda mai zafi. Zafin tanda shine digiri 180-210. Bayan yadi ya bushe, sai ya yi laushi kuma an daidaita nauyin.

7.Duba inganci

Wannan duba inganci ne. Idan akwai wasu lahani a saman masakar, ma'aikatanmu za su iya cire su. Don haka muna tabbatar da cewa kowace mita ta masakarmu tana da inganci mai kyau.

Lokacin Saƙo: Mayu-17-2022