Let‘s know about the process of our dyeing factory!

1.Desizing

This is the first step on the dying factory.First is a desizing process.Gray fabric is put in a large barrel with boiling hot water to wash off some leftovers on the gray fabric.So as later to avoid dying defects during the dying process.Barrels with hot water during the desizing process.So this process takes some time.

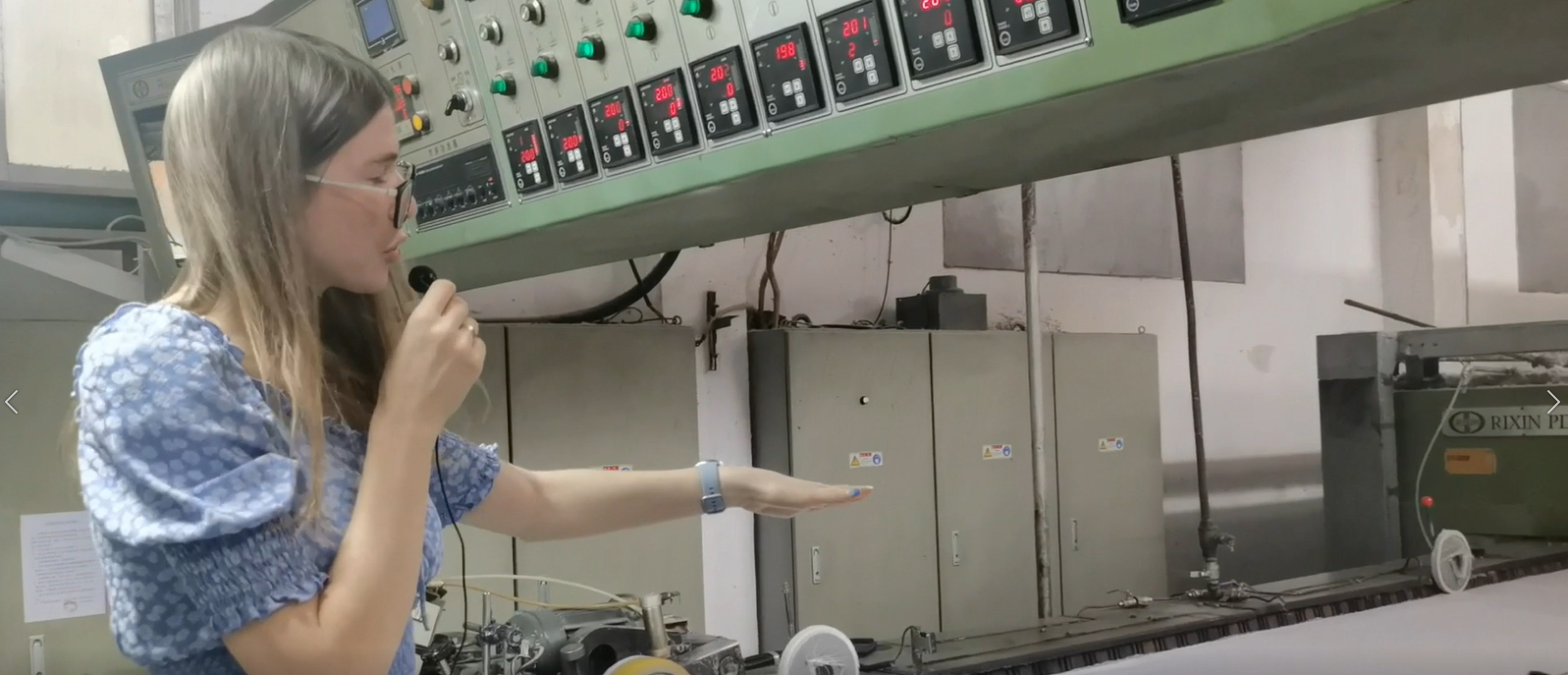

2.Gray fabric setting

Usually the width of the gray fabric is 1.63m,but we require the width of the product 1.55m.So the gray fabric go through the high temperature 160 to 180 degrees to control the width.This process is called gray fabric heat setting.

3.Singeing

The next process in the dyeing factory is singeing.You can see the fire.This is a fire.The gray fabric go through the fire to remove the fluff on its surface.So to make it clean and prepare it for the dyeing.

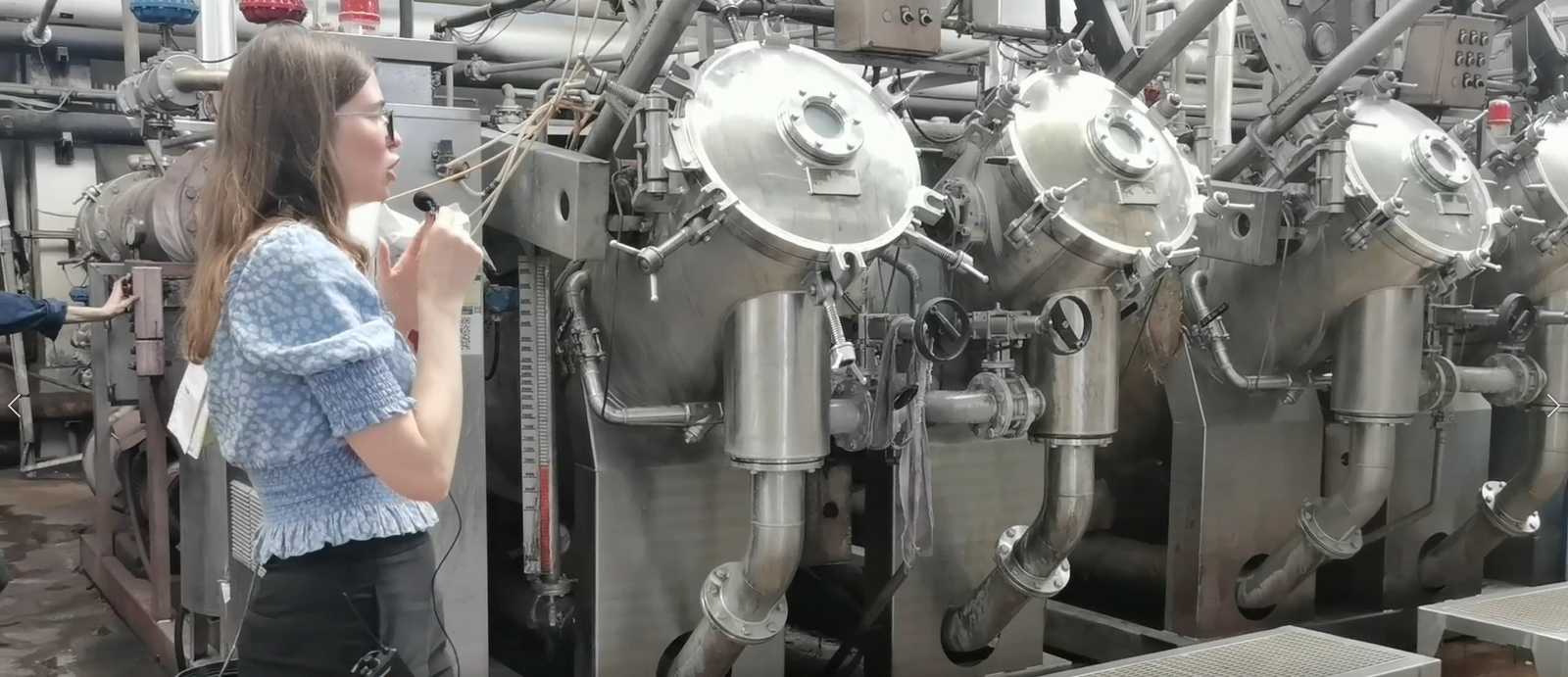

4.Weight Reduction

The next process in the dyeing factory is weight reduction.Before dyeing,the fibers needs to become thinner with alkali.With this process,we can control the weight of fabric and also make it softer.At the same time,we remove the fluff from the surface to prevent dyeing defects.

5.Batch/Lot Dyeing

Batch dyeing or lot dyeing,this is the main process on the dyeing factory.For polyester fibers dyeing,we need dispersed dice and temperature of 80 degrees.It takes 4 hours to dye the polyester fiber for viscose dyeing we need reactive dyes and 85 degrees temperature.It takes 3 hours.Then we need heat preservation for half an hour.After that we need soaping with five tons of water to remove the dyes and impurities.Some customers have special requirements on PH level and environmental production grade of the fabric.so we add more time of soaping to fulfill the customers requirements.

6.Oil setting

After the dyeing is finished,there will be the silicone oil setting machine.The silicone oil will be penetrating and entering the fabric fiber and fully cover in.So that,we can adjust the fabric wight and the hand feeling.After that, fabric goes into a temperature oven.The temperature of the oven is 180-210 degrees.After fabric is dried,it become soft and the weight is adjusted.

7.Quality inspection

This is quality inspection.If there are some defects on the surface of fabric,our workers can remove them.So we make sure that every meter of our fabric is good quality.

Post time: May-17-2022