Masiyazi ngenkqubo yomzi-mveliso wethu wokudaya!

1. Ukusika ubungakanani

Eli linyathelo lokuqala kumzi-mveliso ofayo. Okokuqala yinkqubo yokususa ubungakanani. Ilaphu elingwevu lifakwa kwibhakethi enkulu enamanzi ashushu abilayo ukuze kuhlanjwe ezinye izinto eziseleyo kwilaphu elingwevu. Ukuze kuthintelwe iziphene ezifayo ngexesha lenkqubo yokususa ubukhulu. Iibhakethi ngamanzi ashushu ngexesha lenkqubo yokususa ubukhulu. Ngoko ke le nkqubo ithatha ixesha.

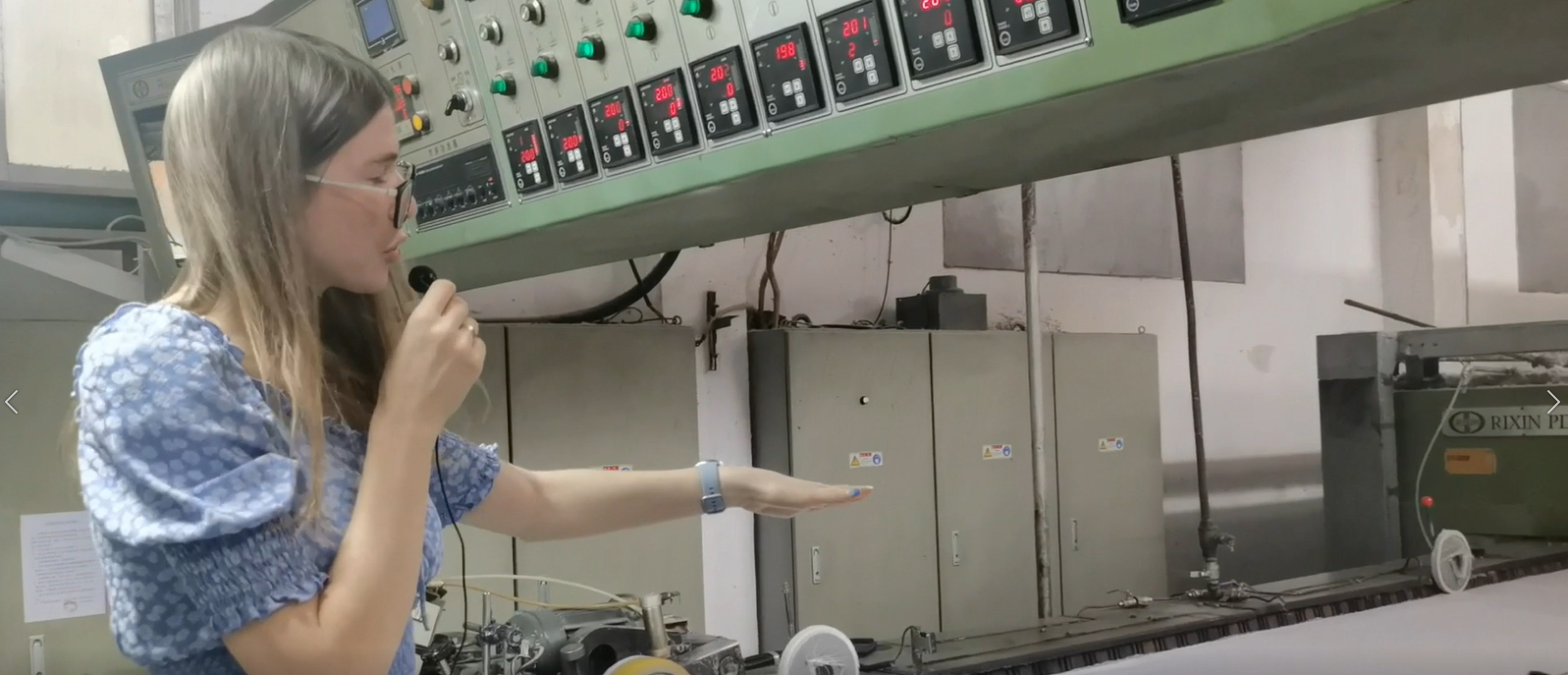

2. Useto lwelaphu elingwevu

Ngokwesiqhelo ububanzi belaphu elingwevu yi-1.63m, kodwa sifuna ububanzi bemveliso yi-1.55m. Ngoko ke ilaphu elingwevu lidlula kubushushu obuphezulu obuyi-160 ukuya kwi-180 degrees ukulawula ububanzi. Le nkqubo ibizwa ngokuba yi-grey fabric heat setting.

3.Ukucula

Inkqubo elandelayo kumzi-mveliso wokudaya kukutsha. Ungawubona umlilo. Lo ngumlilo. Ilaphu elingwevu lidlula emlilweni ukuze lisuse uthuli olukumphezulu walo. Ukuze licoceke kwaye lilungiselele ukudaya.

4.Ukunciphisa Ubunzima

Inkqubo elandelayo kwifektri yokudaya kukunciphisa ubunzima. Ngaphambi kokuba idaye, imicu kufuneka ibe mncinci nge-alkali. Ngale nkqubo, singalawula ubunzima belaphu size silenze lithambe. Kwangaxeshanye, sisusa ulwelo kumphezulu ukuthintela iziphene zokudaya.

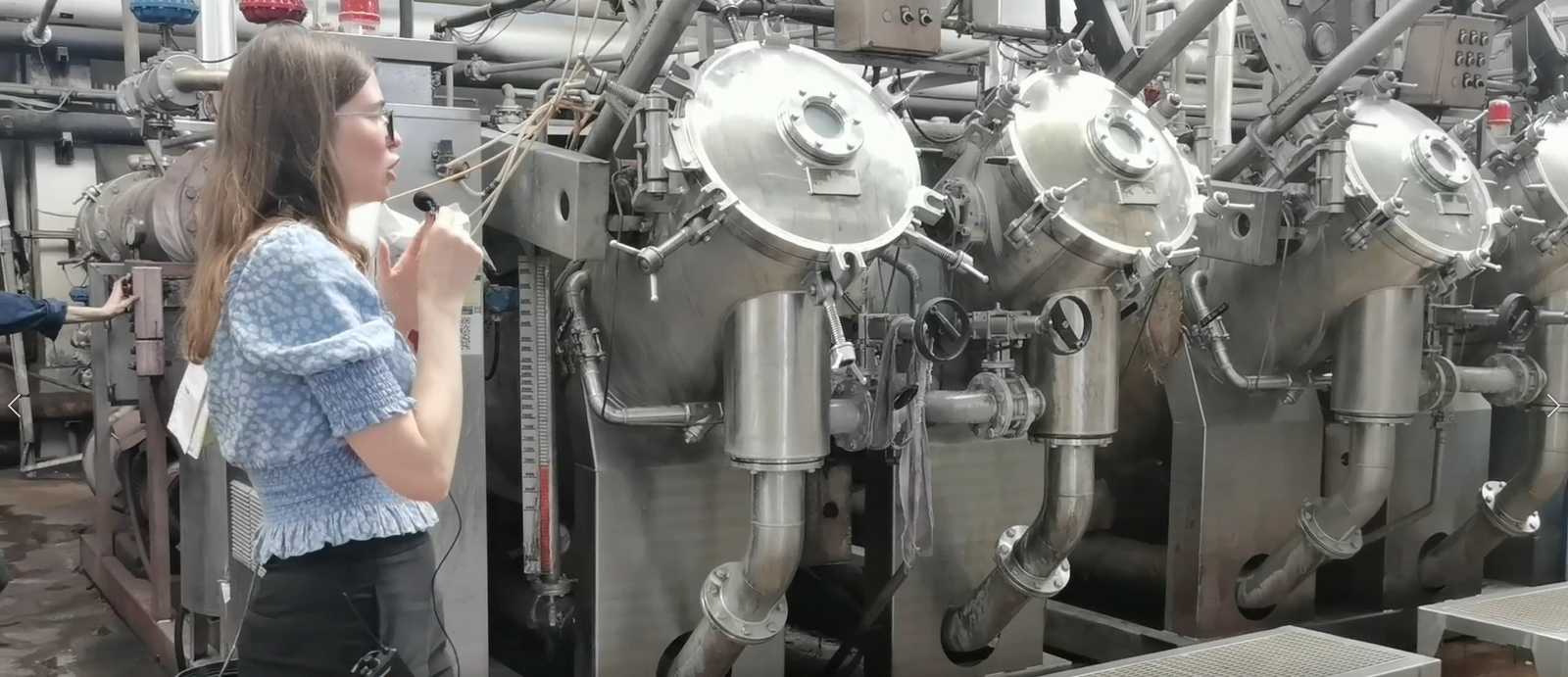

5.Ukudaya ngeBatch/Lot

Ukudaya ngeqela okanye ukudaya ngobuninzi, le yeyona nkqubo iphambili kwifektri yokudaya. Ukudaya ngefayibha zepolyester, sifuna idayisi ezisasazekileyo kunye nobushushu obungama-80 degrees. Kuthatha iiyure ezi-4 ukudaya ifayibha yepolyester ukuze kudaye i-viscose, sifuna iidayi ezisabelayo kunye nobushushu obungama-85 degrees. Kuthatha iiyure ezi-3. Emva koko sifuna ukugcinwa kobushushu kangangesiqingatha seyure. Emva koko sifuna ukusefa ngeetoni ezintlanu zamanzi ukususa iidayi kunye nokungcola. Abanye abathengi baneemfuno ezikhethekileyo kwinqanaba le-PH kunye nomgangatho wemveliso yelaphu. Ngoko ke songeza ixesha elingakumbi lokusefa ukuze sihlangabezane neemfuno zabathengi.

6.Ukuseta ioyile

Emva kokuba kugqityiwe ukudaya, kuya kubakho umatshini wokuseta ioyile ye-silicone. Ioyile ye-silicone iya kungena ize ingene kwifayibha yelaphu ize igqume ngokupheleleyo. Ukuze sikwazi ukulungisa ubunzima belaphu kunye nokuziva kwesandla. Emva koko, ilaphu liya kwi-oven yobushushu. Ubushushu be-oven buyi-180-210 degrees. Emva kokuba ilaphu lomile, lithambe kwaye ubunzima buyalungiswa.

7.Ukuhlolwa komgangatho

Olu luvavanyo lomgangatho. Ukuba kukho iziphene kumphezulu welaphu, abasebenzi bethu banokuzisusa. Ngoko ke siqinisekisa ukuba yonke imitha yelaphu lethu isemgangathweni olungileyo.

Ixesha lokuthumela: Meyi-17-2022