The whole process from yarn to cloth

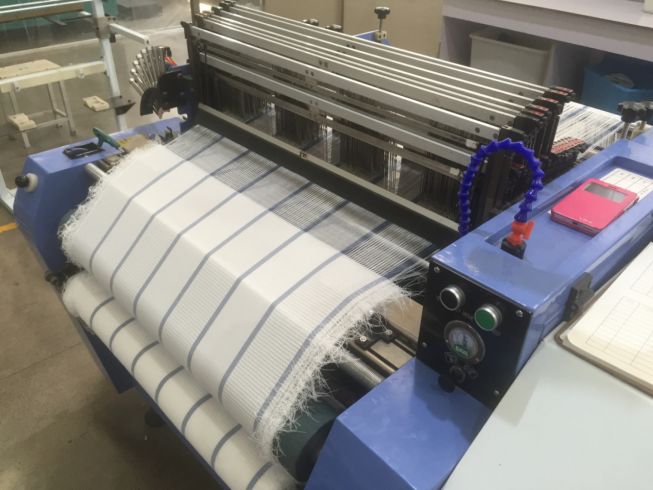

1.Warping process

2.Sizing process

3.Reeding process

4.Weaving

5.Finished product embryo inspection

Dyeing and finishing

1.Fabric pre-treatment

Singeing: Burn off the fluff on the cloth surface to make the cloth surface clean and beautiful, and prevent uneven dyeing or printing defects due to the presence of fluff during dyeing or printing.

Desizing: remove the size of the gray cloth and added lubricants, softeners, thickeners, preservatives, etc., which is beneficial to the subsequent boiling and bleaching processing.

Smelting: remove natural impurities in gray fabrics such as waxy substances, pectin substances, nitrogenous substances and some oils, etc., so that the fabric has a certain degree of water absorption, which is convenient for the adsorption and diffusion of dyes during the printing and dyeing process.

Bleaching: remove the natural pigments on the fibers and natural impurities such as cotton seed hulls, give the fabric the necessary whiteness, and improve the brightness and dyeing effect of dyeing.

Mercerization: Through concentrated caustic soda treatment, stable size, durable gloss and improved adsorption capacity for dyes are obtained, and physical and mechanical properties such as strength, elongation and elasticity are improved.

2.Types of commonly used dyes

Direct dye: Direct dye refers to a dye that can be heated and boiled in a neutral or weakly alkaline medium to directly dye cotton fibers. It has high directness to cellulose fibers, and it is not necessary to use dyes related to chemical methods to color fibers and other materials.

Reactive dye: It is a water-soluble dye with active groups in the molecule, which can covalently bond with the hydroxyl groups on the cellulose molecules under weakly alkaline conditions. The daytime fastness of reactive dyes is generally better. After fully washing and floating, the soaping fastness and rubbing fastness are high.

Acid dyes: It is a kind of water-soluble dyes with acidic groups in the structure, which are dyed in acidic medium. Most of the acid dyes contain sodium sulfonate, soluble in water, bright in color and complete in color spectrum. It is mainly used for dyeing wool, silk and nylon, etc. It has no coloring power to cellulose fibers.

Vat dyes: Vat dyes are insoluble in water. When dyeing, they must be reduced and dissolved in a strong alkaline reducing solution to form leuco-chromatic sodium salts to dye fibers. After oxidation, they will return to insoluble dye lakes and fix them on the fibers. Generally washable, light fastness is higher.

Disperse dyes: Disperse dyes have small molecules and no water-soluble groups in the structure. They are uniformly dispersed in the dyeing solution with the help of dispersants for dyeing. The polyester cotton dyed with disperse dyes can be dyed polyester fiber, acetate fiber and polyester amine fiber, and becomes a special dye for polyester.

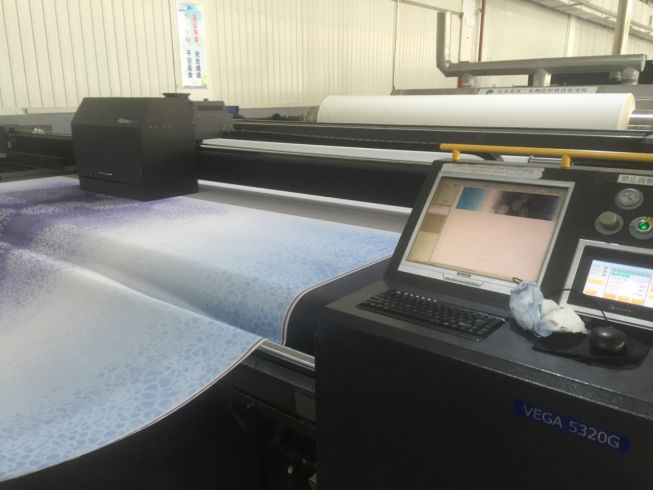

Finishing

Stretching, weft trimming, shaping, shrinking, whitening, calendering, sanding, raising and shearing, coating, etc.

Post time: Jan-07-2023